Special wire box for prefabricated laminated plates and construction method thereof

A technology of laminated boards and wire boxes, applied in the direction of manufacturing tools, lighting and heating equipment, ceramic molding machines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below the present invention is further described:

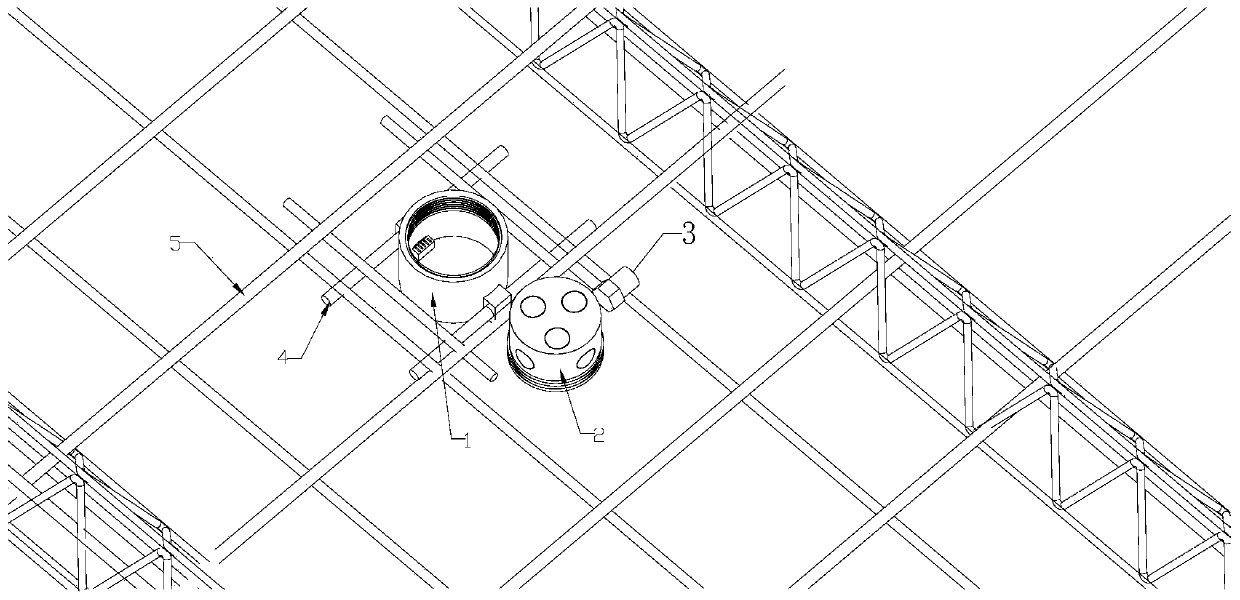

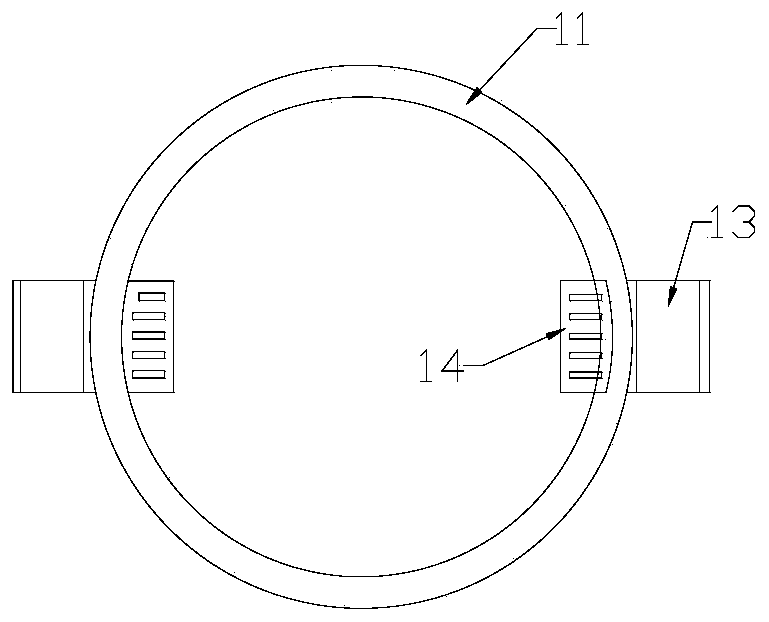

[0022] Such as Figure 1-5 As shown, a special line box for prefabricated laminated boards, which includes a bottom box 1 and a top box 2, the bottom box 1 consists of a box wall 11 in the shape of a through tube and two steel bar piercing blocks fixed on the box wall 11 13, the steel bar piercing block 13 is provided with a steel bar hole; the upper part of the bottom box is provided with an internal thread 12, and the lower part is provided with a screw fixing groove 14; the top box 2 is composed of a top plate 22 and a box body 21. All are provided with pipe hole 23, and box body bottom is provided with external screw thread 24.

[0023] The construction method of the above-mentioned special wire box for prefabricated laminated boards is carried out according to the following steps:

[0024] 1) Put steel bars 4 in the steel bar holes on both sides of the bottom box 1.

[0025] 2) The screw fixing groove side of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com