Optical functional surface and laser radar outer cove using the same

A laser radar and optical function technology, applied in the optical field, can solve the problems of inability to meet the aesthetic needs of different customer designs, affect the appearance of the laser radar system, affect the receiving efficiency of the detector, etc., and achieve compatibility and hardware assembly and docking. The effect of smooth, strong plasticity and diversified structure and shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

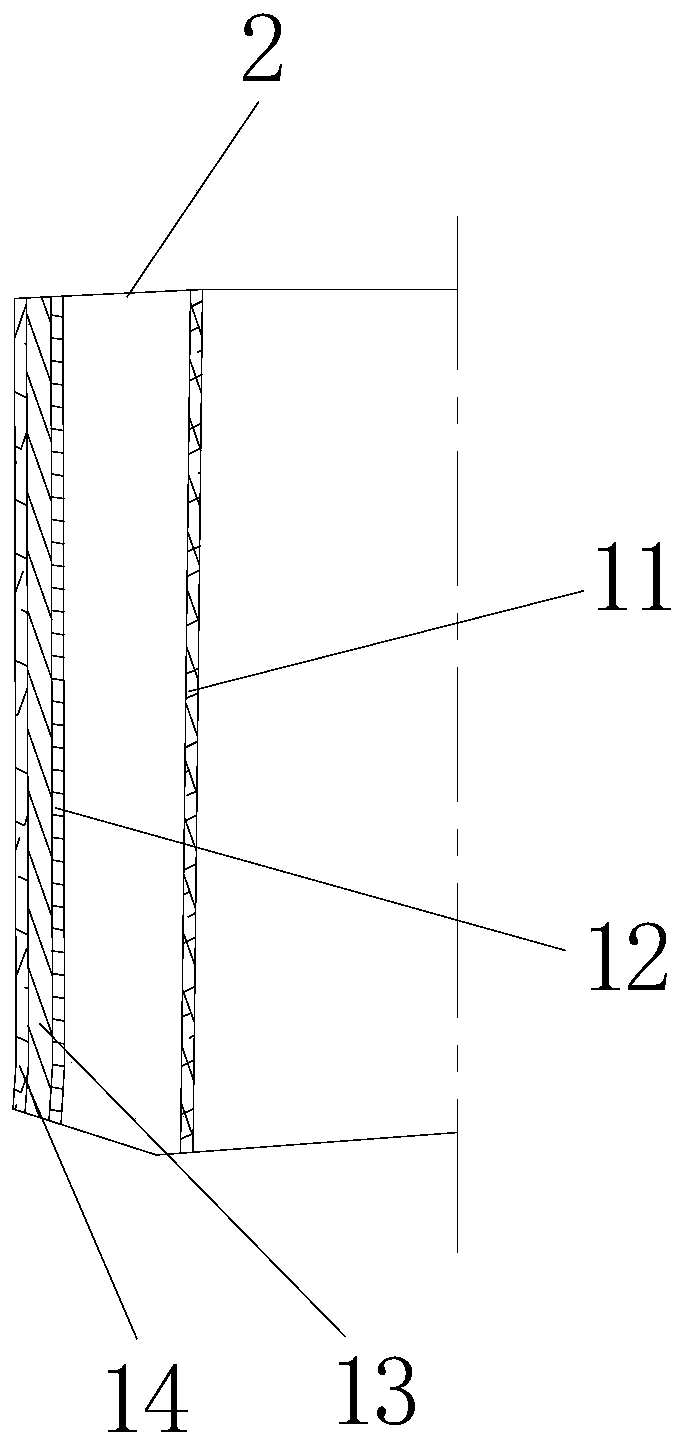

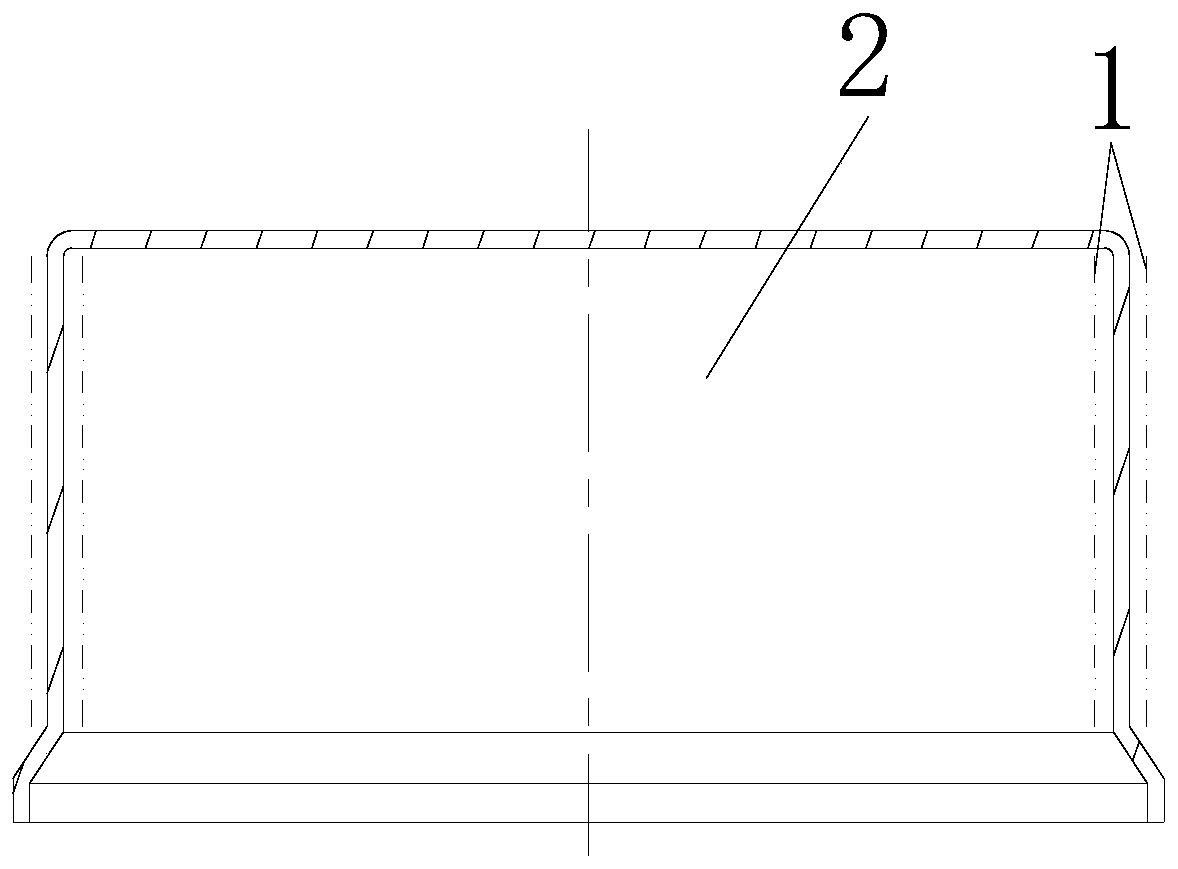

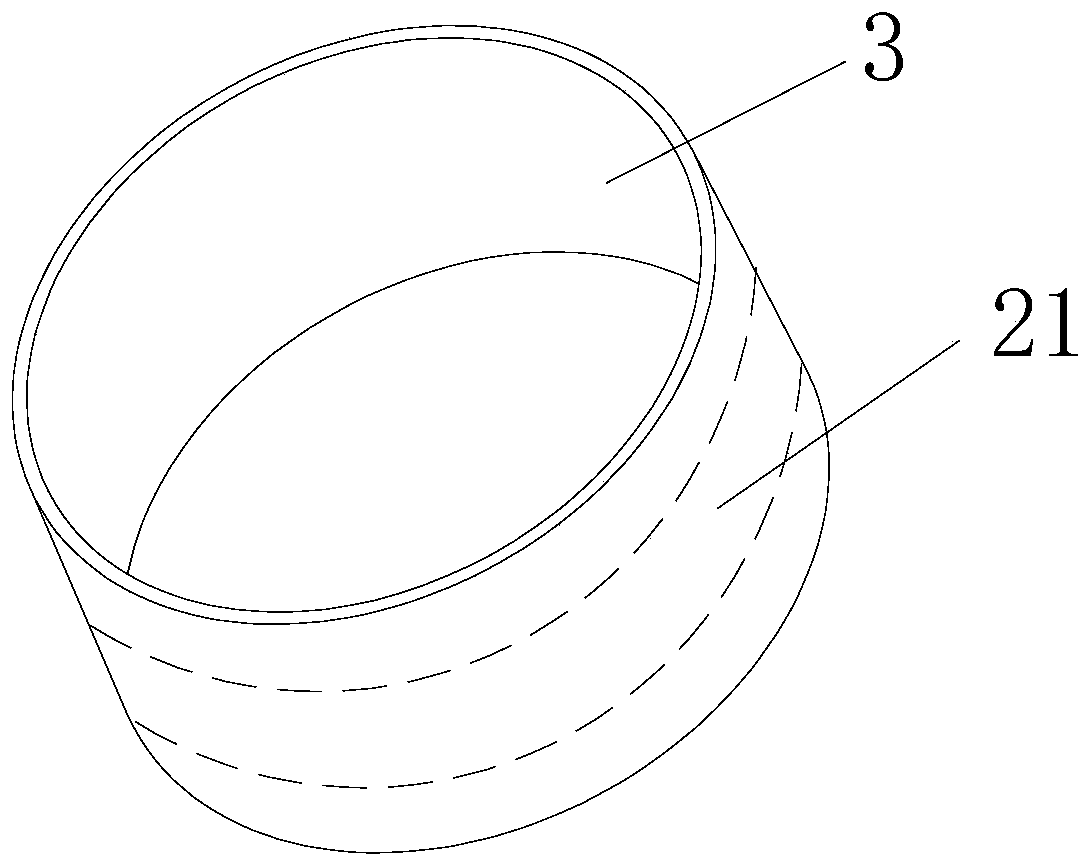

[0030] see figure 1 with figure 2 , the present invention provides an embodiment: an optical function surface 1, including an inner strengthening film 11, an outer strengthening film 12, a waterproof film 13 and an anti-reflection film 14; the inner strengthening film 11 is arranged on the inner side of the cover, and the The outer reinforcing film 12 is arranged on the outer side of the cover, and the waterproof film 13 and the anti-reflection film 14 are sequentially pasted on the outer reinforcing film 12 . It makes it possible to realize the high penetration function of the established ultraviolet and infrared lasers, and the penetration rate can reach 95%; it can be better used to enhance the receiving and transmitting efficiency of the laser radar.

[0031] In the present invention, the surface roughness Ra of the lidar cover can reach below 20nm, but it is no...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com