Arc extinguishing structure of high-voltage DC relay

A high-voltage direct current and relay technology, applied in the direction of relays, electromagnetic relays, electromagnetic relay details, etc., can solve the problems of arc extinguishing space reduction, volume reduction, and affecting arc extinguishing effects, so as to increase arc extinguishing space and enhance magnetic field Intensity, the effect of ensuring arc extinguishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

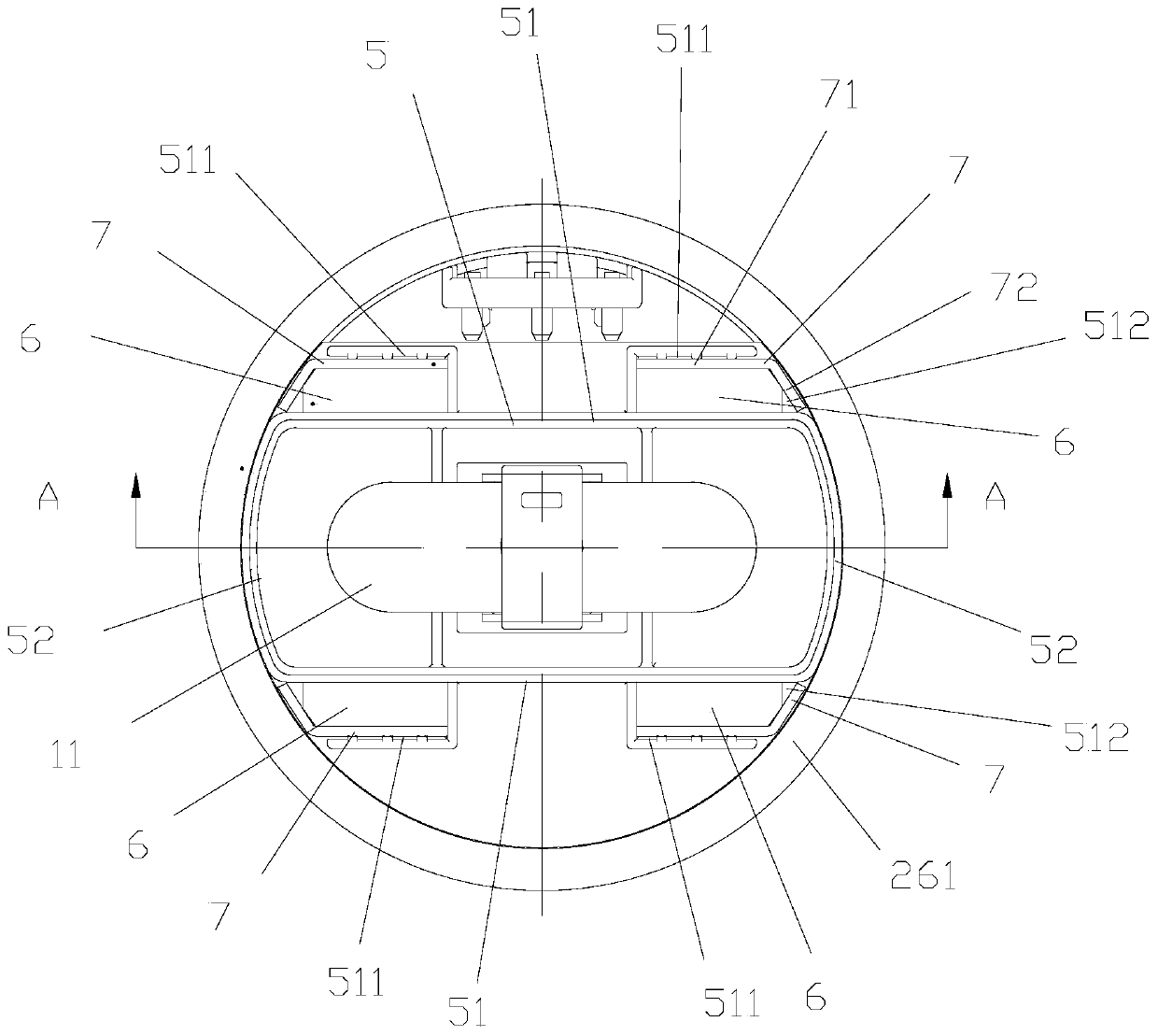

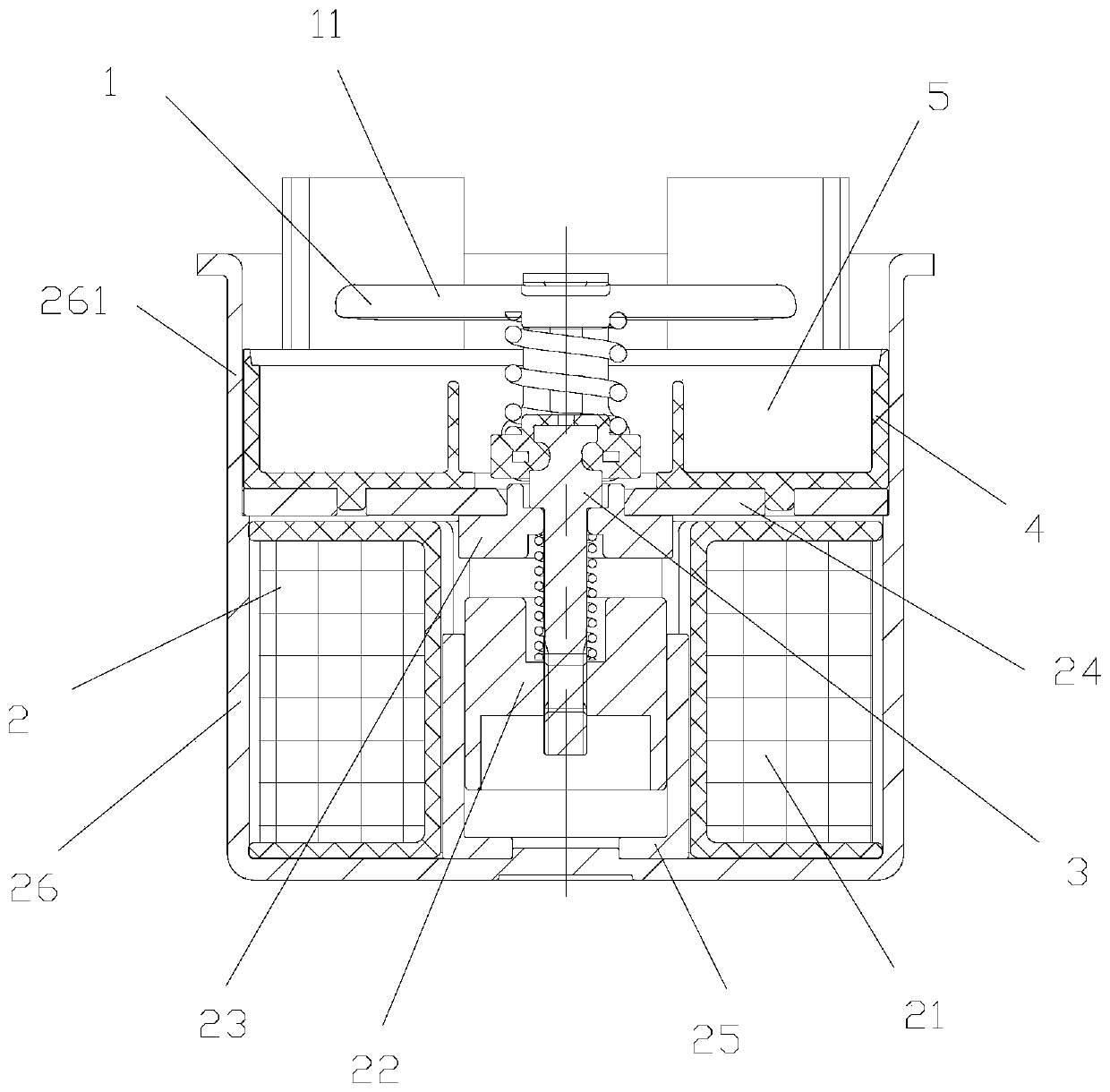

[0016] see Figure 1 to Figure 2 As shown, the arc extinguishing structure of a high-voltage DC relay of the present invention is applied to a high-voltage DC relay. The high-voltage DC relay includes a contact part 1 and a magnetic circuit part 2. The magnetic circuit part 2 adopts a direct-acting magnetic circuit structure. The contact part 1 is set on the upper part, and the magnetic circuit part 2 is set on the lower part. The contact part 1 includes two static contact lead-out ends (that is, two load lead-out ends, not shown in the figure) and a moving spring part. The moving spring part adopts a straight Sheet-type moving reed (also known as bridge-type moving reed), the moving spring parts include moving reed 11 and the moving contacts at both ends of the moving reed, the moving contacts can be directly formed on the moving reed 11 The two ends should also be riveted on the two ends of the moving reed 11 as separate parts. The magnetic circuit part 2 includes a coil 21,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com