Fully-sealed high-voltage DC relay

A high-voltage direct current, fully sealed technology, applied in the direction of relays, electromagnetic relays, electromagnetic relay details, etc., can solve problems such as long arcing time, polluted cavity, small arc extinguishing space, etc., to increase insulation resistance and expand openings The effect of increasing the area and increasing the arc extinguishing space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

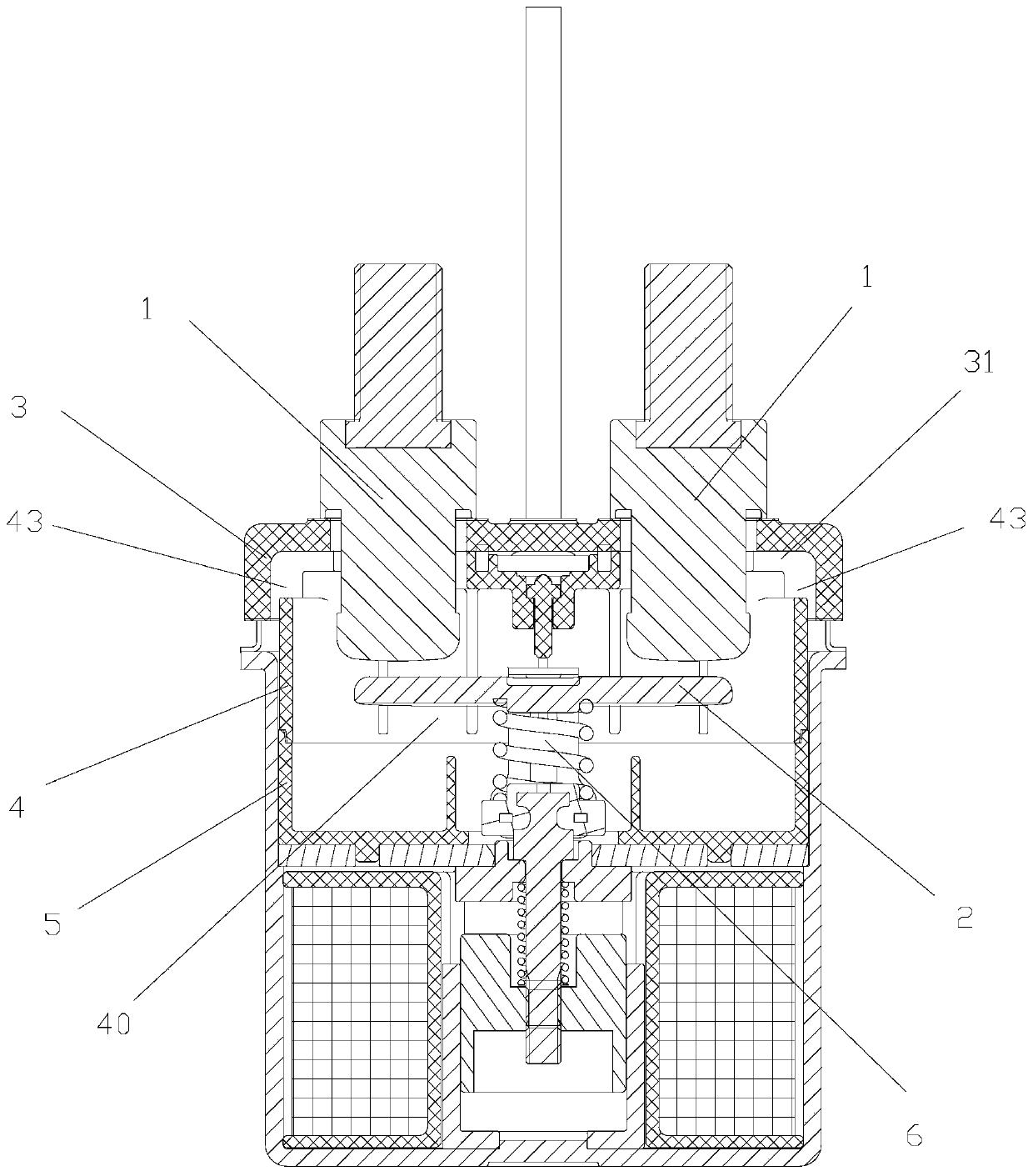

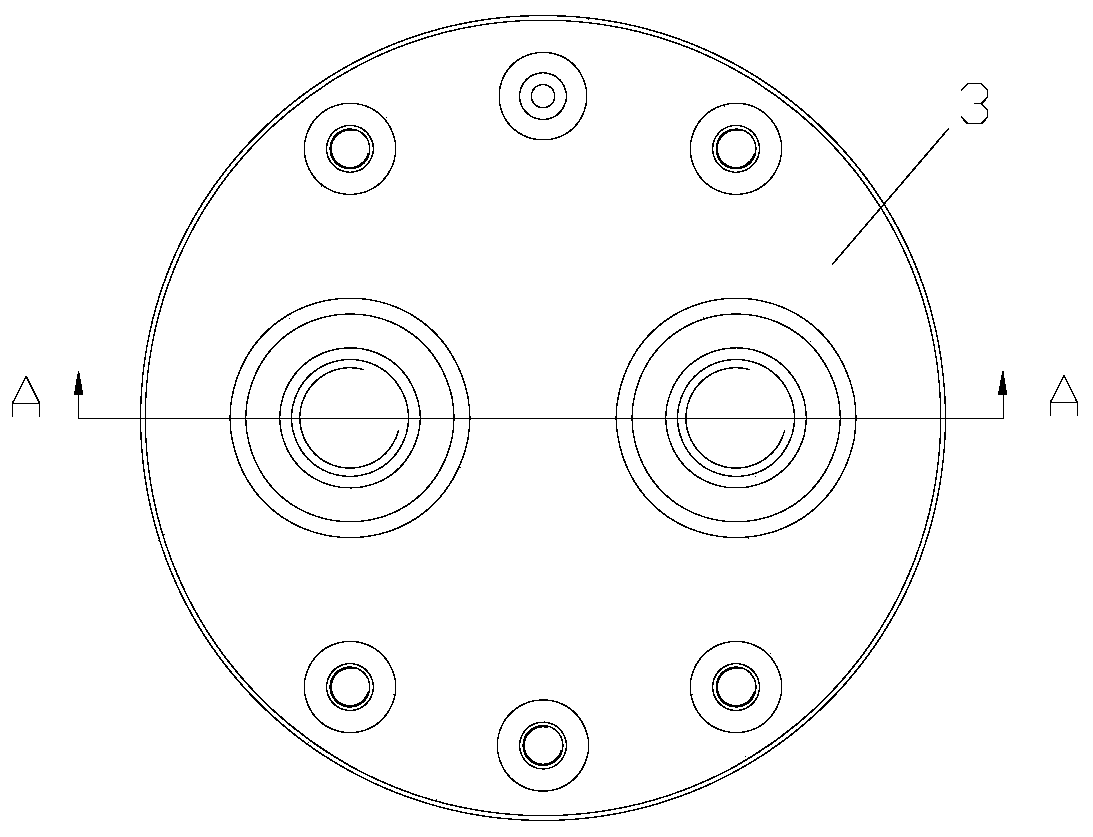

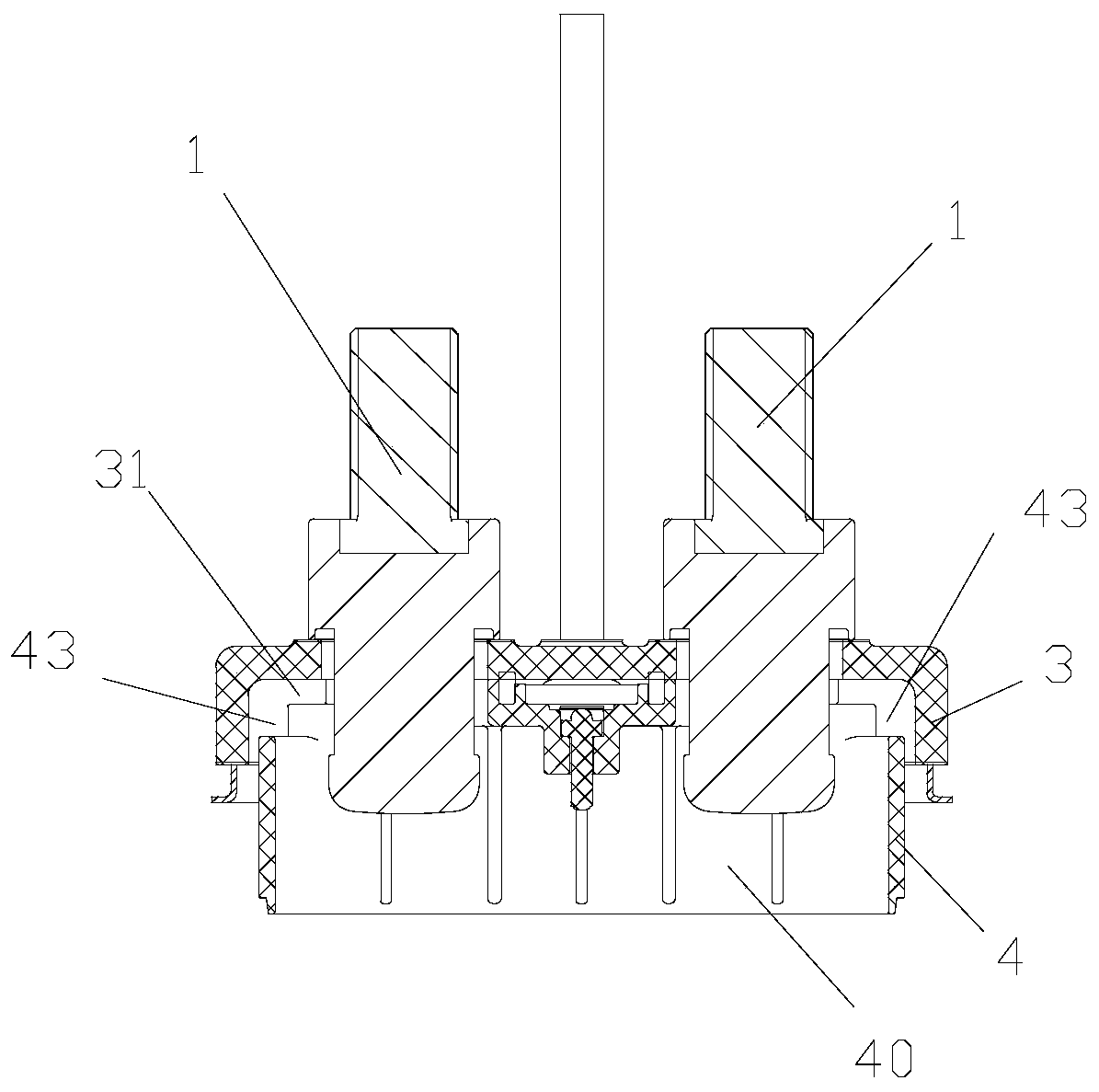

[0024] see Figure 1 to Figure 7 As shown, a fully sealed high-voltage DC relay of the present invention includes two static contact terminals 1, a moving reed 2, a ceramic cover 3 and a plastic frame; the plastic frame is composed of an upper plastic frame 4 and a lower plastic frame 5 , the plastic frame is divided into an upper plastic frame 4 and a lower plastic frame 5 in order to be able to install the push rod assembly 6, the bottom end of the static contact lead-out end 1 is provided with a static contact, and the two ends of the moving reed 2 are provided with a moving contact, In this embodiment, the static contact lead-out end 1 and the static contact are of an integrated structure, and the moving reed and the movable contact are also of an integrated structure; of course, the static contact can also be a separate part, the static contact riveted at the bottom of the lead-out end of the static contact; the movable contact can also be a separate part, and the movable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com