Patch used for testing reflectivity of automobile lamp parts and reflectivity testing method

A reflective patch and component reflection technology, which is applied in the preparation of test samples, measurement of scattering characteristics, measurement devices, etc., can solve the problems of time-consuming and laborious detection, difficulty in obtaining objective and reasonable reflectance test data, and inaccuracy of products , to achieve the effect of high degree of customization, simple and reliable operation, and improved contrast efficiency

Active Publication Date: 2019-06-04

HASCO VISION TECHNOLOGY CO LTD

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Although there are corresponding instruments for detecting the reflectance of parts in the prior art, due to the diversification of part shapes in the actual production process and the variability of the location of reflectivity detection points, it is difficult to obtain a more objective and reasonable measurement of the actual product. Reflectivity test data, each test is time-consuming and inaccurate

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

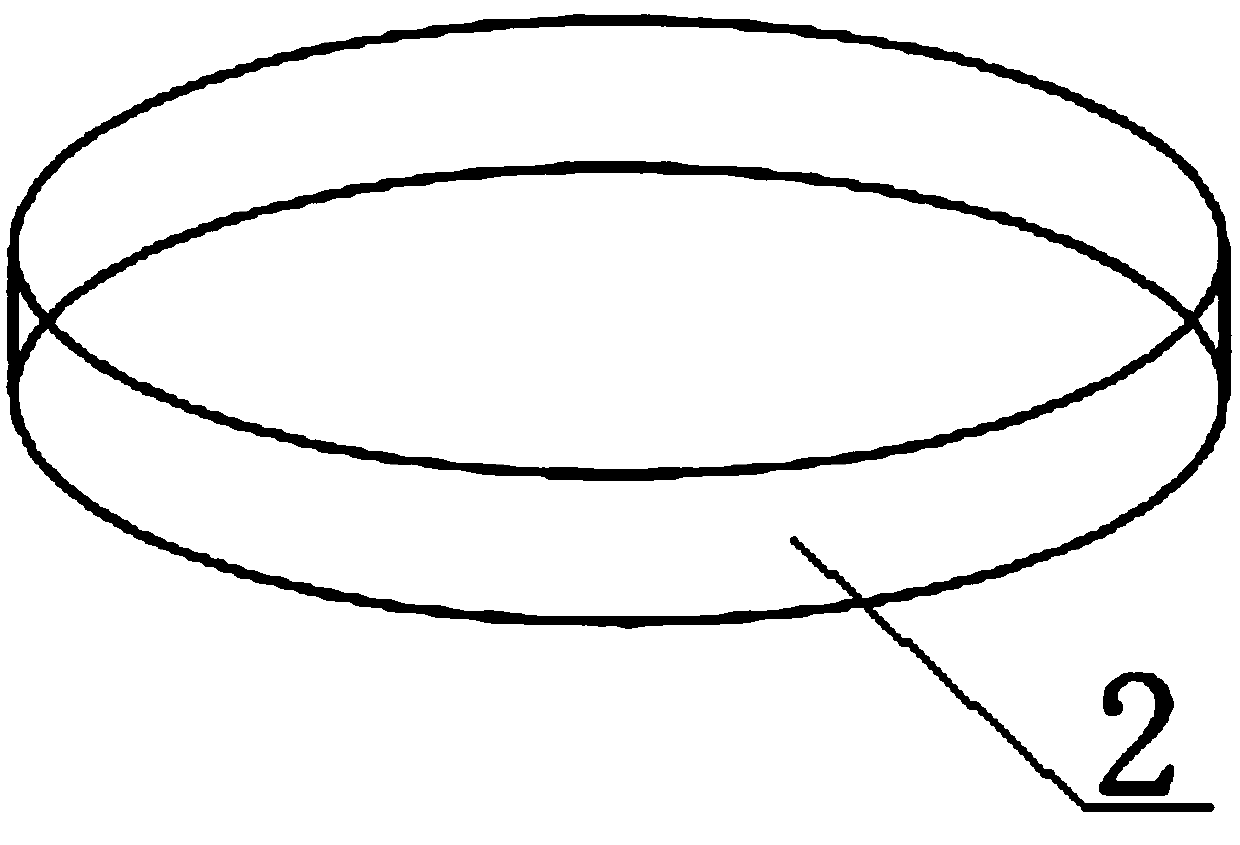

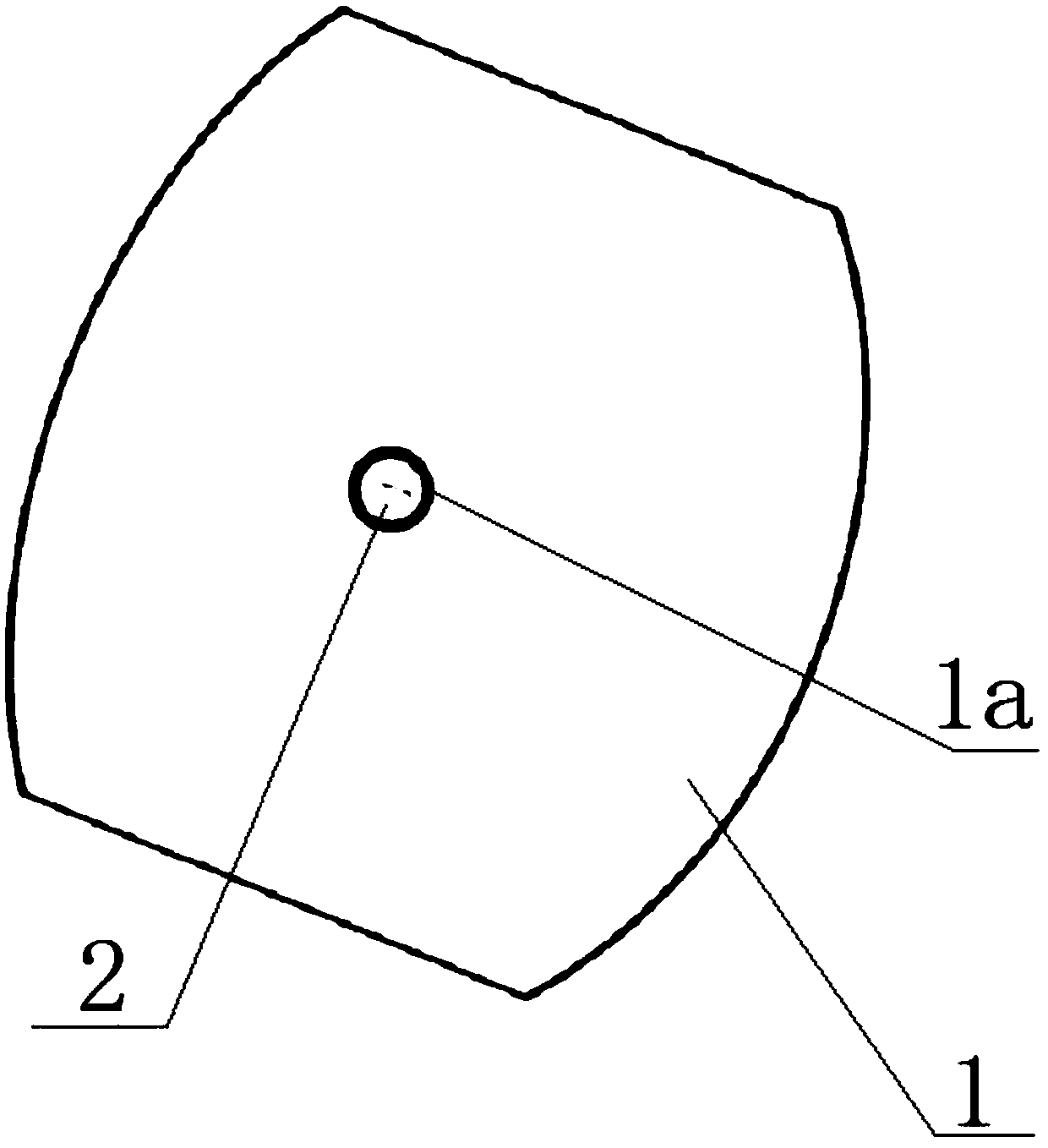

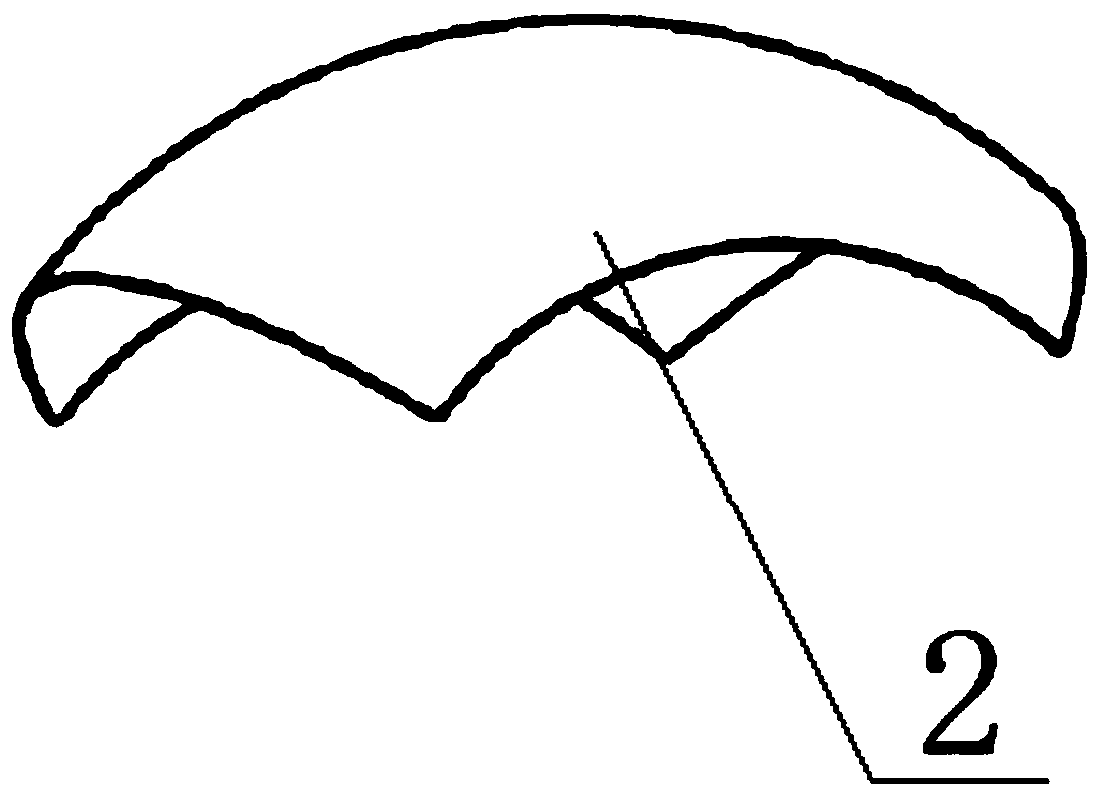

[0032] Such as Figure 1 ~ Figure 3 As shown, the patch used for the reflectivity test of automobile lamp parts includes the lamp part 1 to be tested, and the lamp part to be tested is provided with a reflective patch on its part reflective surface;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a patch used for testing the reflectivity of automobile lamp parts and a reflectivity testing method. The patch comprises an automobile lamp part to be tested, wherein the automobile lamp part to be tested is provided with a reflective patch on the reflection surface thereof; the reflective patch is specifically a flat cylindrical or thin-film reflective patch, the specific dimensions of the reflective patch are the same as those of a detection hole at the point to be detected of the automobile lamp part to be tested in size and thickness, the reflective patch is identical to the reflection surface of the automobile lamp part to be tested in performance parameters such as material and roughness, and the actual shape of the reflective patch can be correspondingly adjusted according to the structure and shape of a positioning hole of the automobile lamp part to be tested. The reflective patch is placed in the detection hole, then surface treatment is carried outon the part, and the reflective patch is taken out after the treatment and then placed on reflectivity detection equipment for reflectivity detection. The patch measures the reflectivity of the specific position, can meet the experimental detection effects of accuracy and ability of being close to the actual use state and provides a reliable experimental conclusion.

Description

technical field [0001] The invention relates to the detection field of components, in particular to a patch applied to the reflectance test of automobile lamp parts and a reflectance test method. Background technique [0002] At present, in the lighting field of automobile lamps, the technical core structure is the reflective surface of the lamp, and the optical performance of a lamp is closely related to the design and processing technology of the reflective surface of the lamp. There are many technical requirements, for example, the reflectivity of light intensity is one of the important technical indicators of the performance of automotive lamp parts. [0003] Although there are corresponding instruments for detecting the reflectance of parts in the prior art, due to the diversification of part shapes in the actual production process and the variability of the location of reflectivity detection points, it is difficult to obtain a more objective and reasonable measurement ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N21/55G01N21/01G01N1/28

Inventor 杨斌严浩南常林会刘果汤家伟金煜吴俊翁添捷

Owner HASCO VISION TECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com