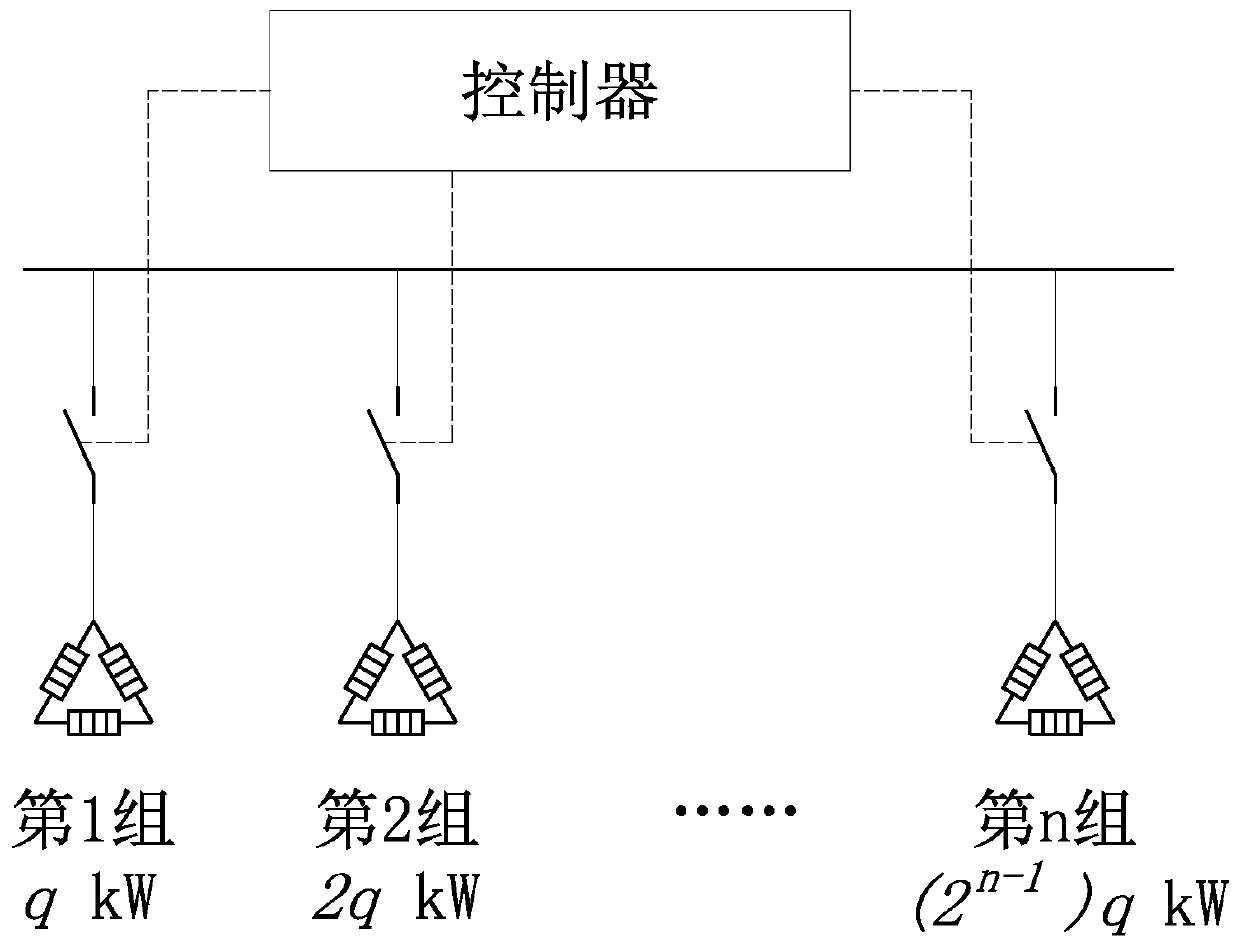

Temperature Control Method of Resistance Furnace Based on Arrangement and Combination of Geometric Sequences

A temperature control method, permutation and combination technology, applied in furnace control devices, furnaces, furnace components, etc., can solve the problems of low temperature control accuracy, easy to generate harmonics, low cost, etc., achieve high temperature control accuracy, overcome disturbance, No harmonic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

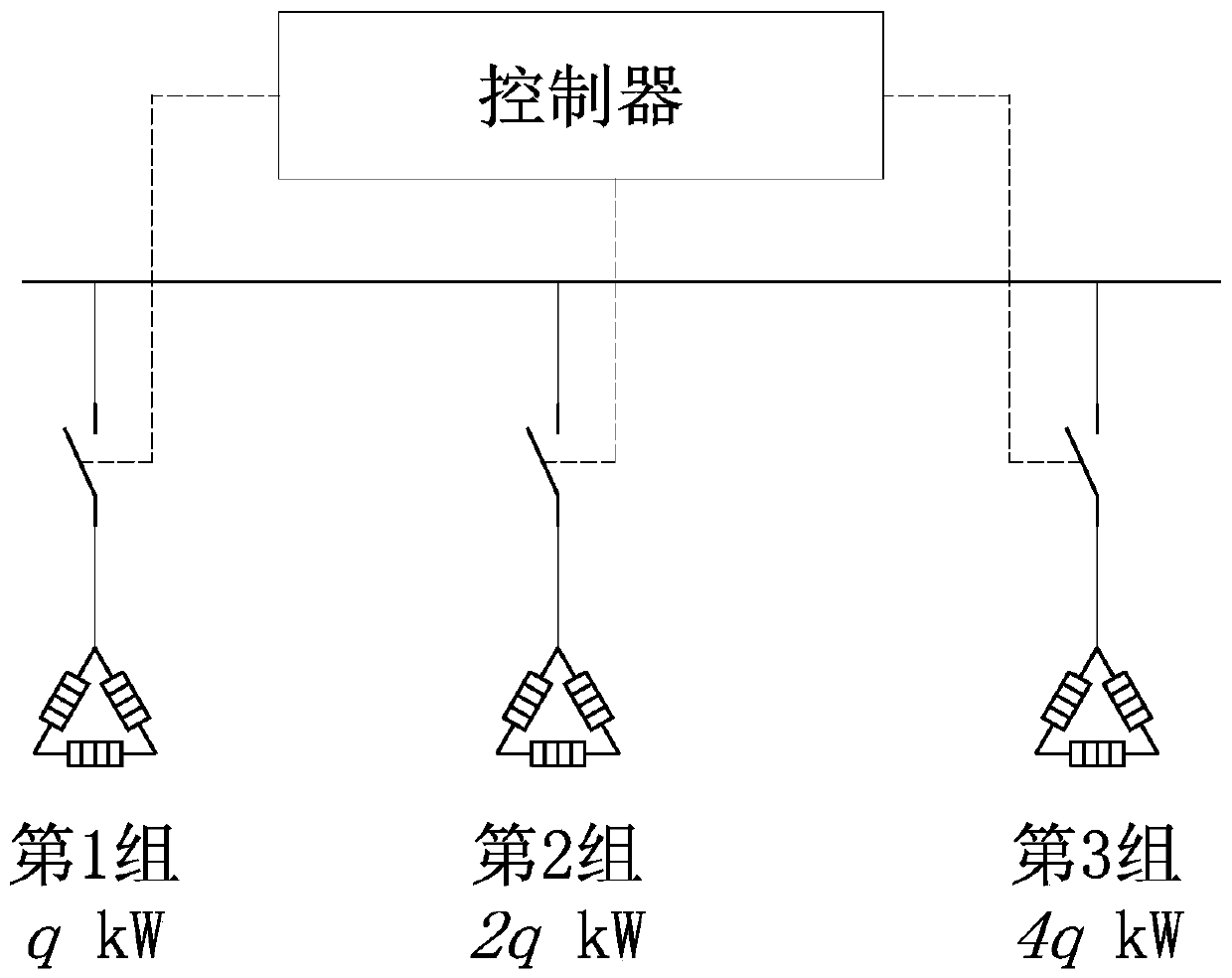

Embodiment 1

[0076] refer to figure 2 , in the first embodiment of the present invention, the grouping quantity of a single resistance furnace is recorded as 3, and the 1st, 2nd, and 3rd groups are recorded respectively, and the power of the 1st group is recorded as q, then the 2nd group is 2q, and the 3rd group is 4q. The power is 7q; if the installed power of the resistance furnace is p, then q=p / 7; the total output power is Arrange the above 7 kinds of power from small to large, that is, q, 2q, 3q, 4q, 5q, 6q, 7q, and the difference between the two adjacent powers is q; perform PID adjustment calculation and convert it into the required q for actual output Integer multiple, denoted as f k , build an index table, as shown in Table 1:

[0077] Table 1 Corresponding index table when a single resistance furnace is divided into 3 groups

[0078] f k

The serial number of the input group Corresponding output power 0 none 1 1 q 2 2 2q 3 1,2 q+2q ...

Embodiment 2

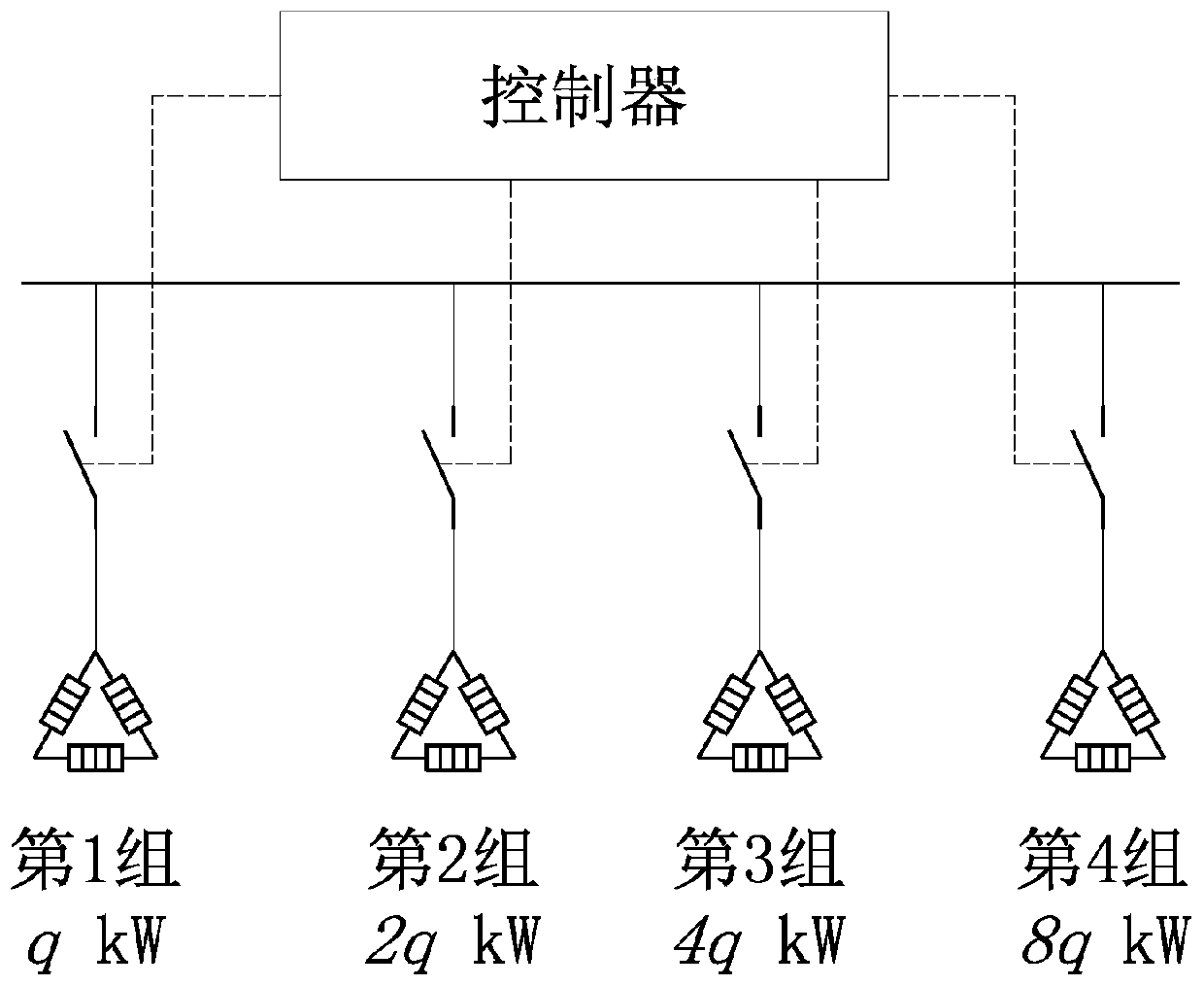

[0082] refer to image 3 , in the second embodiment of the present invention, the grouping quantity of a single resistance furnace is recorded as 4, and the 1st, 2nd, 3rd, 4th groups are recorded respectively, and the power of the 1st group is recorded as q, then the 2nd group is 2q, and the 3rd group is 4q , the fourth group is 8q, and the total power is 15q; if the installed power of the resistance furnace is p, then q=p / 15; the total output power is Arrange the above 15 powers from small to large, that is, q, 2q, 3q, 4q, 5q, 6q, 7q, 8q, 9q, 10q, 11q, 12q, 13q, 14q, 15q, the difference between two adjacent powers is q; carry out PID adjustment calculation and convert it into an integer multiple of q required for actual output, which is recorded as fk, and an index table is established, as shown in Table 2:

[0083] Table 2 Corresponding index table when a single resistance furnace is divided into 4 groups

[0084] f k

The serial number of the input group ...

Embodiment 3

[0088] refer to Figure 4 , in the third embodiment of the present invention, the grouping quantity of a single resistance furnace is recorded as 5, and the first, 2, 3, 4, and 5 groups are recorded respectively, and the power of the first group is recorded as q, then the second group is 2q, and the third group is 4q, the fourth group is 8q, the fifth group is 16q, and the total power is 31q; if the installed power of the resistance furnace is p, then q=p / 31; the total output power is Arrange the above 31 kinds of power from small to large, that is, q, 2q, 3q, 4q,..., 30q, 31q, and the difference between two adjacent powers is q; perform PID adjustment calculation and convert it into the required q for actual output Integer multiples of , denoted as f k , build an index table, as shown in Table 3:

[0089] Table 3 Corresponding index table when a single resistance furnace is divided into 5 groups

[0090]

[0091]

[0092] It can be seen from Table 3 that only 5 grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com