Secondary device soft strap misoperation-preventive locking design method

A secondary equipment, anti-misoperation locking technology, applied in the direction of electrical components, information technology support systems, circuit devices, etc., can solve problems such as misoperation accidents, misoperations, and equipment inaction, and achieve the effect of avoiding misoperation accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

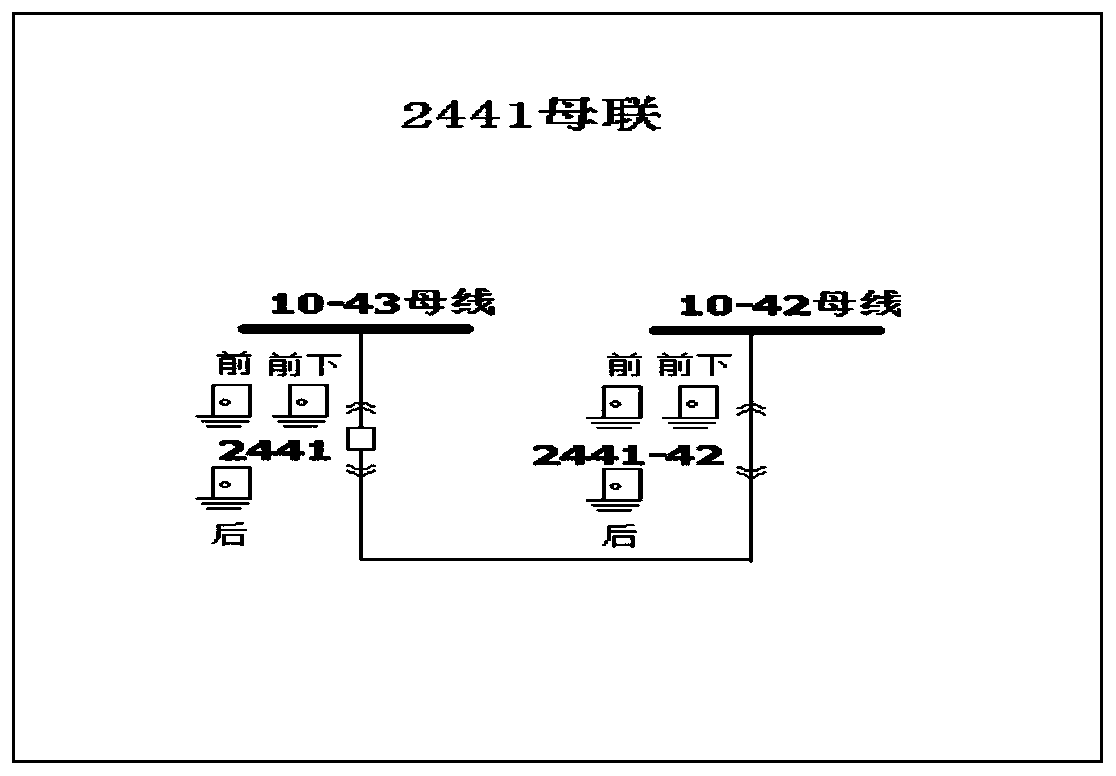

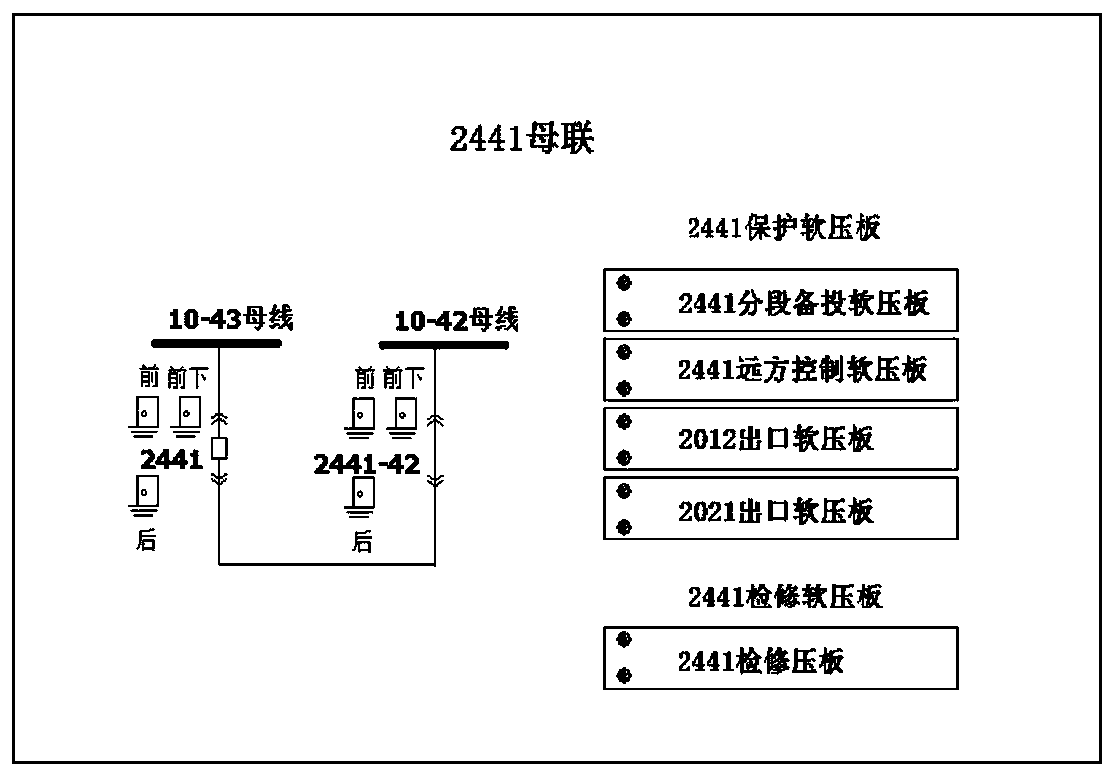

[0015] see figure 1 and figure 2 , the secondary equipment soft platen anti-misoperation locking design method of the present invention comprises the following steps:

[0016] 1. On the basis of the original interface, the anti-mistake management software is improved, and the virtual knob of the soft pressure plate of the secondary equipment is added to the interval of the primary equipment.

[0017] 2. Review the special regulations for on-site operation of the substation, combine the logic sequence of the switching operation of the primary equipment, and compile the anti-mistake logic formula including the soft pressure plate of the secondary equipment.

[0018] Pull the 2012 switch conditions: 2012 trolley is pushed in, 2011 switch is off, 2441 switch is closed, 2441 trolley is pushed in, 2022 switch is closed, 2022 trolley is pushed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com