Novel cooling and heat dissipating device installed in motor casing

A technology for motor casings and heat dissipation devices, which is applied in cooling/ventilation devices, electromechanical devices, casings/covers/supports, etc., and can solve problems such as poor heat dissipation effects, lack of versatility of motor heat dissipation devices, and low motor heat dissipation efficiency , to achieve the effect of improved motor efficiency, simple structure, and reduced steel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be described in detail with reference to the accompanying drawings.

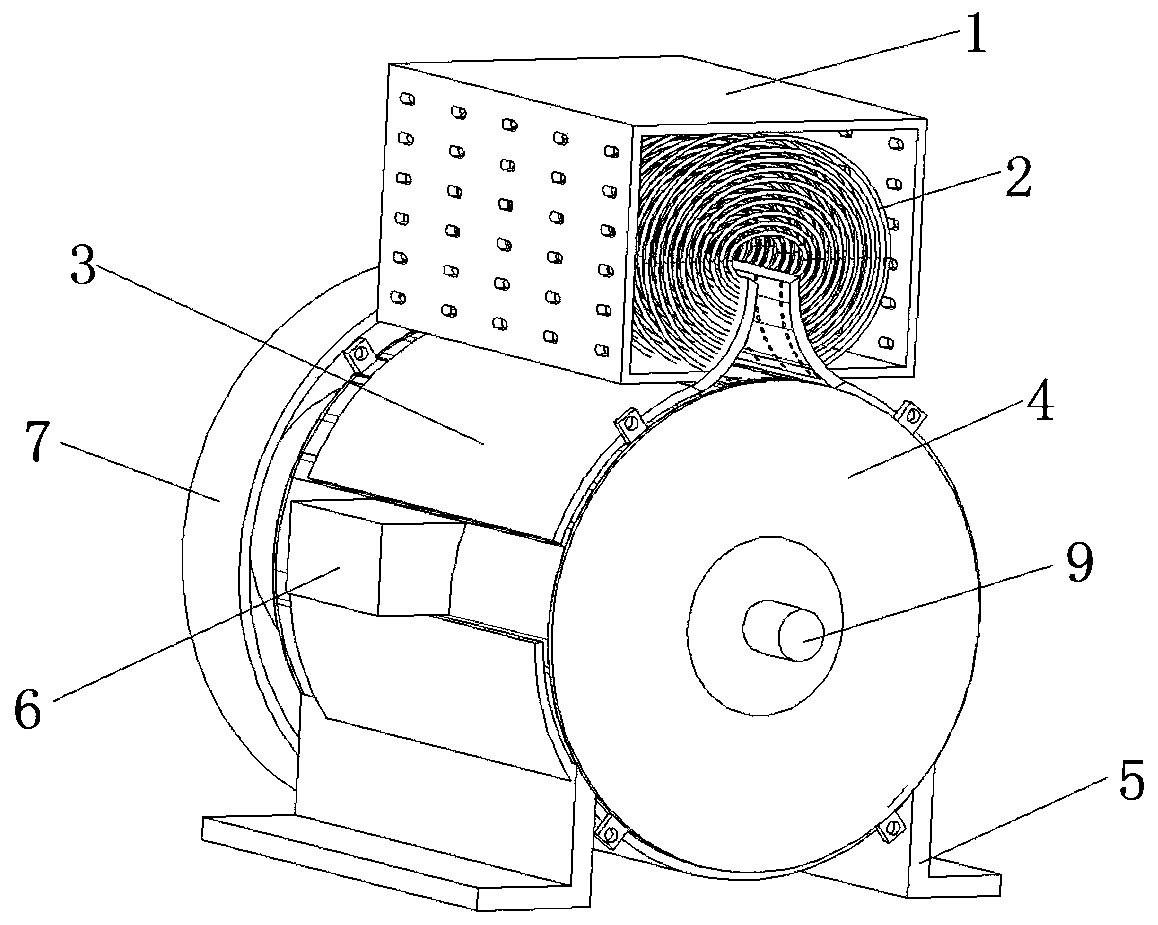

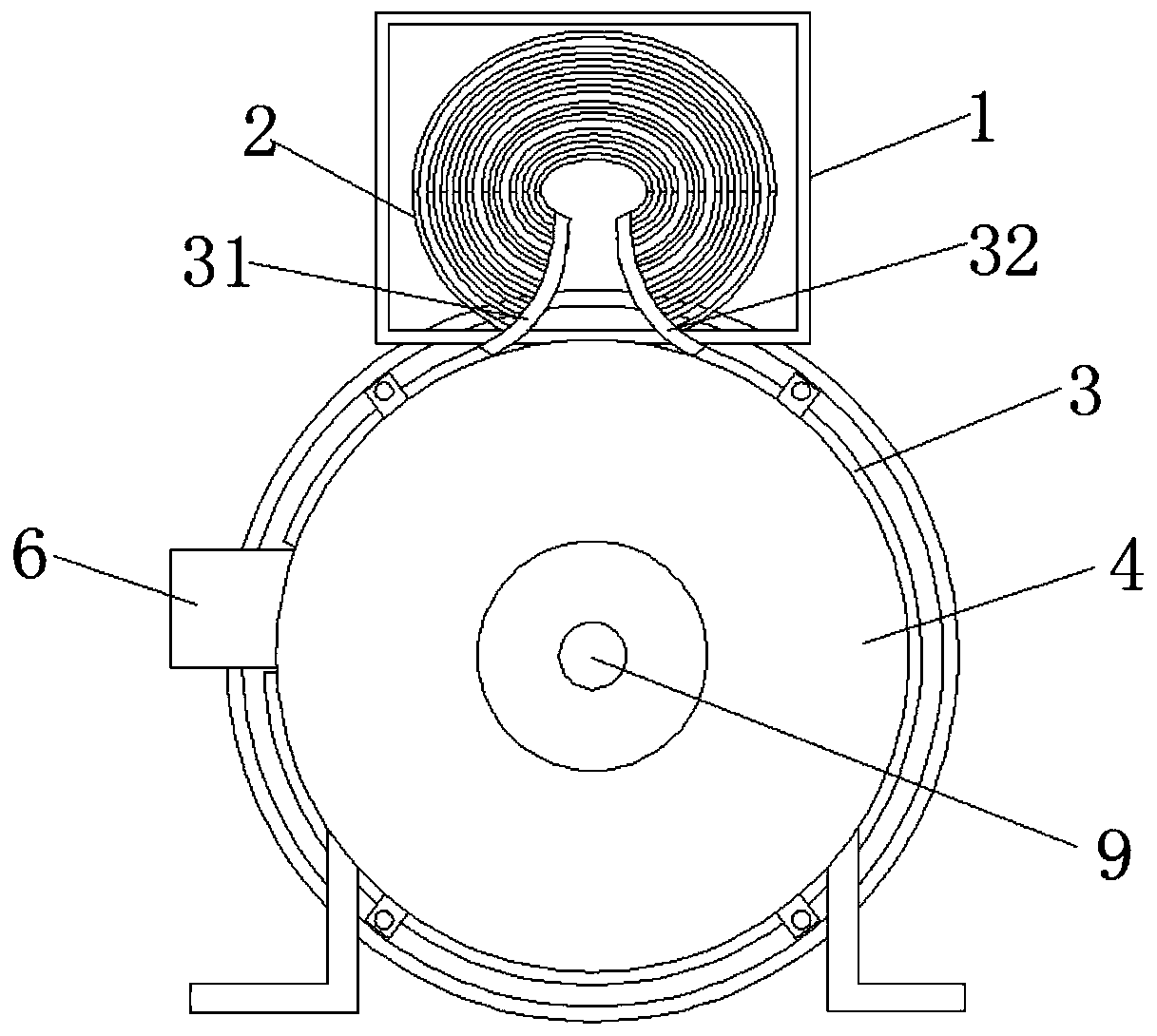

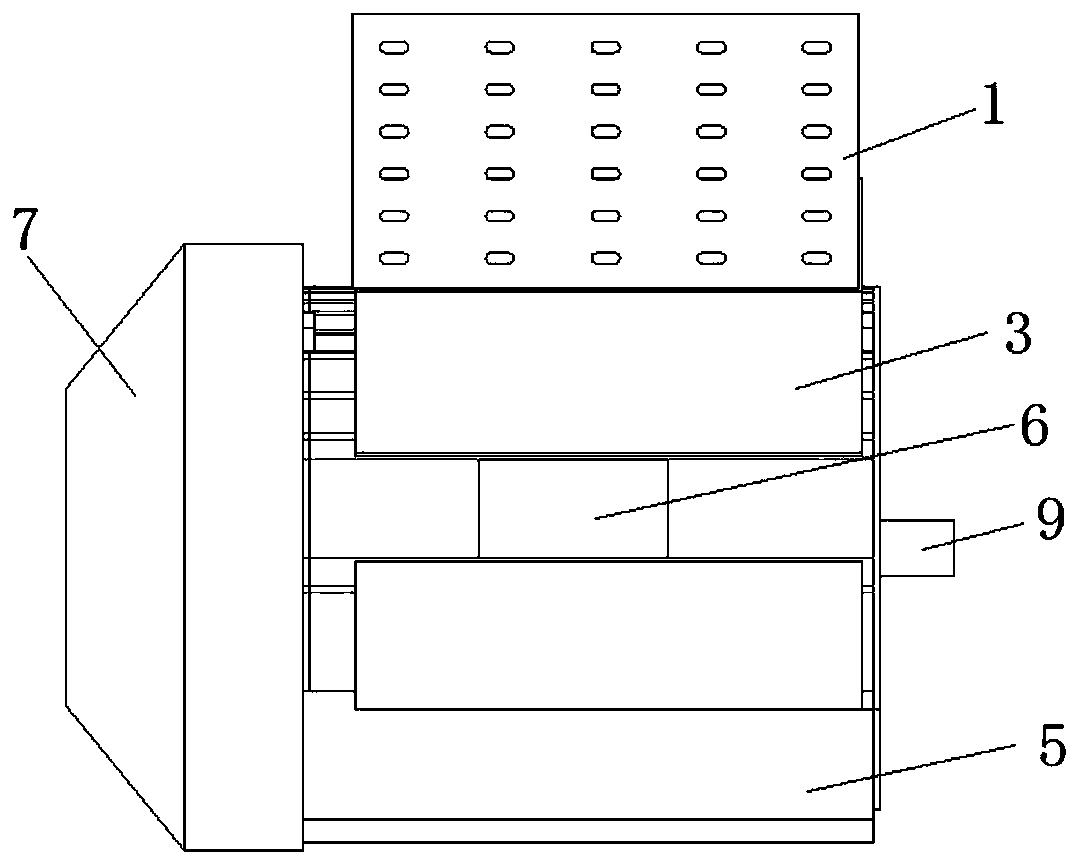

[0026] like figure 1 As shown, a new type of cooling and heat dissipation device installed in the motor casing in this embodiment includes a heat dissipation sleeve 3 and a heat dissipation pipe group installed above the heat dissipation sleeve 3. The heat dissipation sleeve 3 is a cavity structure, and the heat dissipation sleeve 3 is filled with cooling liquid, and the heat dissipation pipe group is composed of several heat dissipation pipes. The heat dissipation pipe 2 is a hollow tubular structure with both ends open. The heat dissipation sleeve 3 is attached to the outer surface of the motor 4 shell. The two ends are respectively communicated with the heat dissipation sleeve 3, and there is a heat dissipation gap between the body of the heat dissipation pipe 2 and the outer wall of the casing of the motor 4. The motor 4 is connected and fixed with the mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com