A kind of cigarette spice additive and preparation method thereof

A technology for additives and flavors, applied in the field of cigarette flavor additives and their preparation, can solve the problems of reducing harm and reducing scorch, weakening aroma, and not being able to increase flavor, and achieving the effects of improving cigarette flavor, reducing irritation, and inhibiting release.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

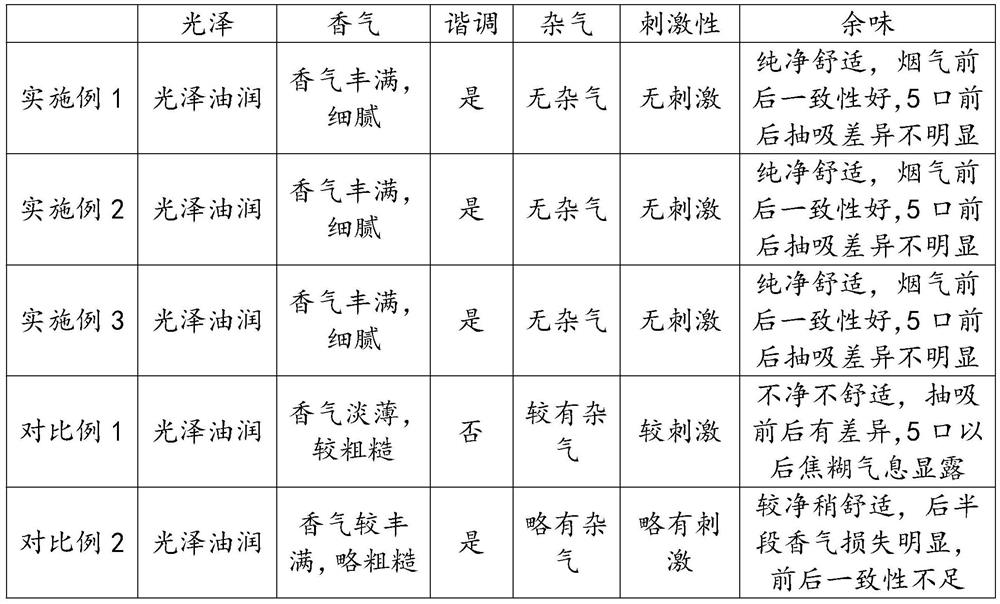

Examples

preparation example Construction

[0045] The preparation method of the cigarette spice additive comprises the steps of:

[0046] The first step is to add the calcium fruit extract and flavor enhancer to ethanol in sequence, raise the temperature to 45-50°C, and stir at a constant speed of 100r / min for 30min;

[0047] In the second step, adding farnesol, 2-acetylpyrrole, phenylethyl acetate, and L-phenylalanine to the above mixture in turn, assisting ultrasonic waves to aid in dissolution, ultrasonic waves for 10-12 minutes, to obtain the cigarette flavoring additive ;

[0048] The flavoring method of the cigarette flavoring additive is as follows: spray the cigarette flavoring additive evenly on the shredded tobacco (the amount of the cigarette flavoring additive added is controlled at 0.05% of the mass of the shredded tobacco), and then spray an appropriate amount of distilled water to make the moisture content of the shredded tobacco reach 19-21%. Airtightly store for 120-130min, dry the shredded tobacco in...

Embodiment 1

[0050] A flavor additive for cigarettes, made of the following raw materials in parts by weight: 10 parts of calcium fruit extract, 7 parts of flavor enhancer, 1 part of farnesol, 0.5 part of 2-acetylpyrrole, 1 part of phenylethyl acetate, L - 0.6 parts of phenylalanine, 20 parts of ethanol;

[0051] The cigarette spice additive is made by the following steps:

[0052] In the first step, add the calcium fruit extract and flavor enhancer to ethanol in sequence, raise the temperature to 45°C, and stir at a constant speed of 100r / min for 30min;

[0053] In the second step, adding farnesol, 2-acetylpyrrole, phenylethyl acetate, and L-phenylalanine to the above mixture in sequence, assisting ultrasonic wave to aid dissolution, and ultrasonic wave for 10 minutes to obtain the cigarette flavoring additive.

Embodiment 2

[0055] A flavor additive for cigarettes, made of the following raw materials in parts by weight: 11 parts of calcium fruit extract, 8 parts of flavor enhancer, 1.5 parts of farnesol, 0.6 part of 2-acetylpyrrole, 1.5 parts of phenylethyl acetate, L - 0.8 parts of phenylalanine, 25 parts of ethanol;

[0056] The cigarette spice additive is made by the following steps:

[0057] The first step is to add the calcium fruit extract and flavor enhancer to ethanol in sequence, raise the temperature to 48°C, and stir at a constant speed of 100r / min for 30min;

[0058] In the second step, adding farnesol, 2-acetylpyrrole, phenylethyl acetate, and L-phenylalanine to the above mixture in sequence, assisting ultrasonic wave to aid dissolution, and ultrasonic wave for 11 minutes to obtain the cigarette flavoring additive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com