A full-frame spectacle frame automatic painting equipment

A technology for automatic painting and spectacle frames, applied in the direction of painting booths, spraying devices, etc., can solve the problems of damage to the paint on the spectacle frames, large labor consumption, low production efficiency, etc., to improve the painting effect, ensure the painting effect, and improve the pass rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

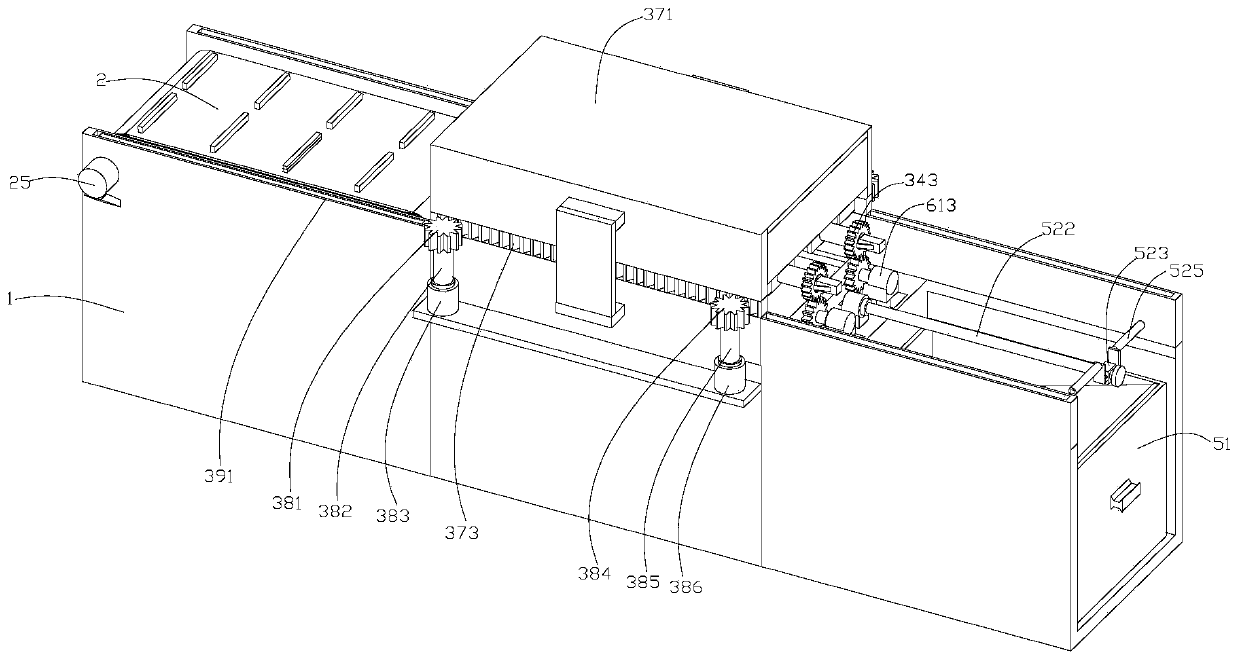

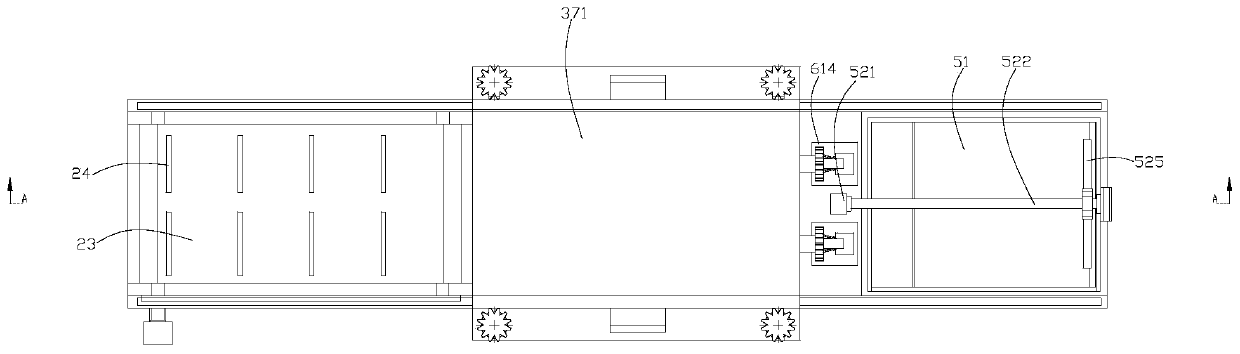

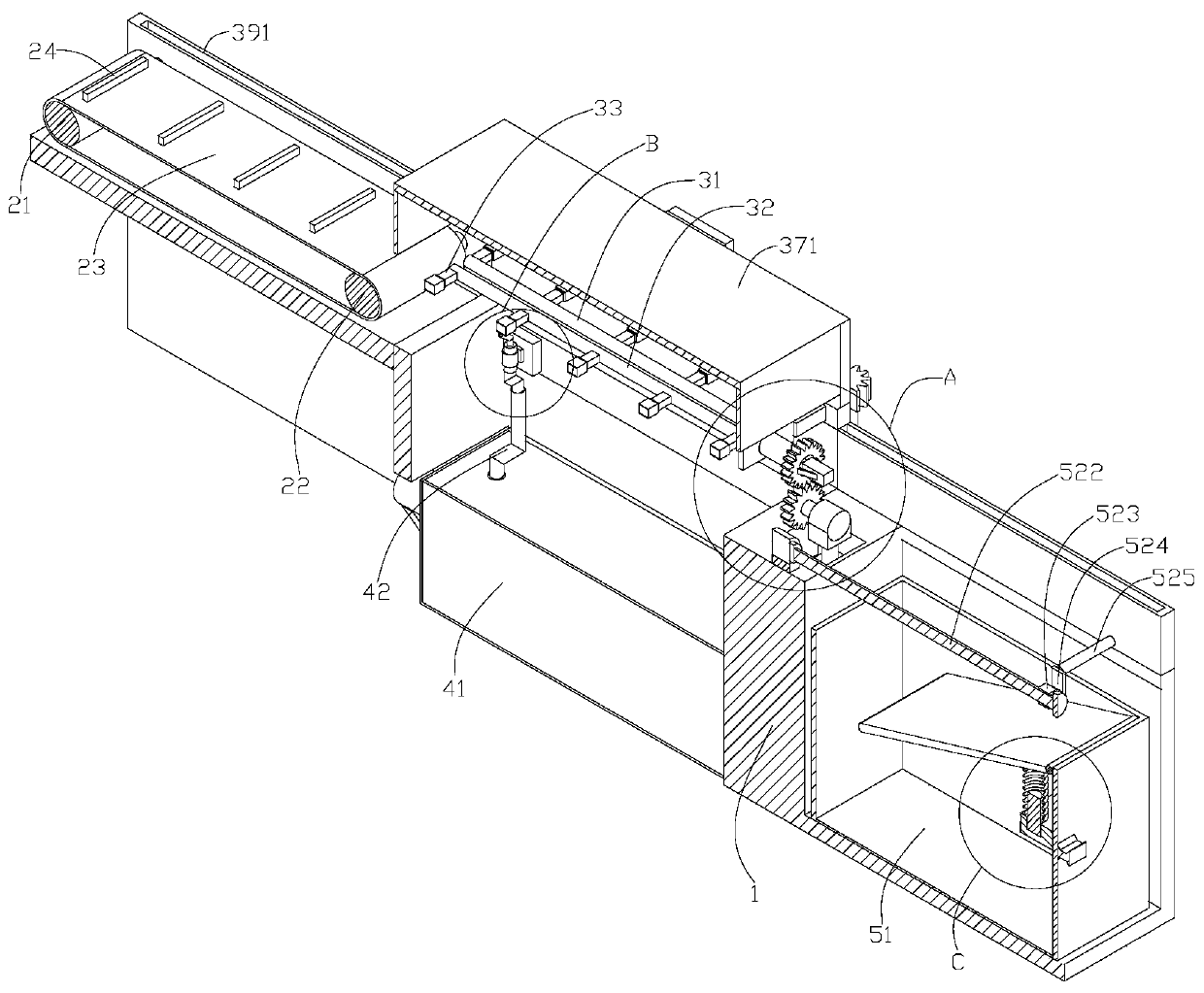

[0030] Such as Figure 1-13 The automatic painting equipment for a full-frame spectacle frame includes a frame body 1, a transmission device 2, a support device, a painting device and a discharge device. The frame body 1 is a metal frame, and the transmission device 2 is located on the At the left end position of the frame body 1, the transmission device 2 can transport and transmit the spectacle frame to be painted. Specifically, the transmission device 2 includes a driving roller 21, a driven roller 22, a conveyor belt 23, a supporting member 24 and a fifth The driving member 25, the driving roller 21 and the driven roller 22 are all metal rollers, the conveyor belt 23 is a belt, and the conveyor belt 23 is sleeved on the driving roller 21 and the driven roller 22, and the contact member 24 It is a metal plate, and there are a plurality of the supporting parts 24, which are uniformly bonded on the conveyor belt 23. The fifth driving part 25 is a motor that can be purchased d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com