Telescopic conveying device

A transmission device and telescopic technology, which is applied in the field of telescopic transmission devices, can solve the problems that the transmission device occupies a large space, is difficult to apply to the job site, and has poor flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] For ease of understanding, the present invention will be further described below in conjunction with the accompanying drawings.

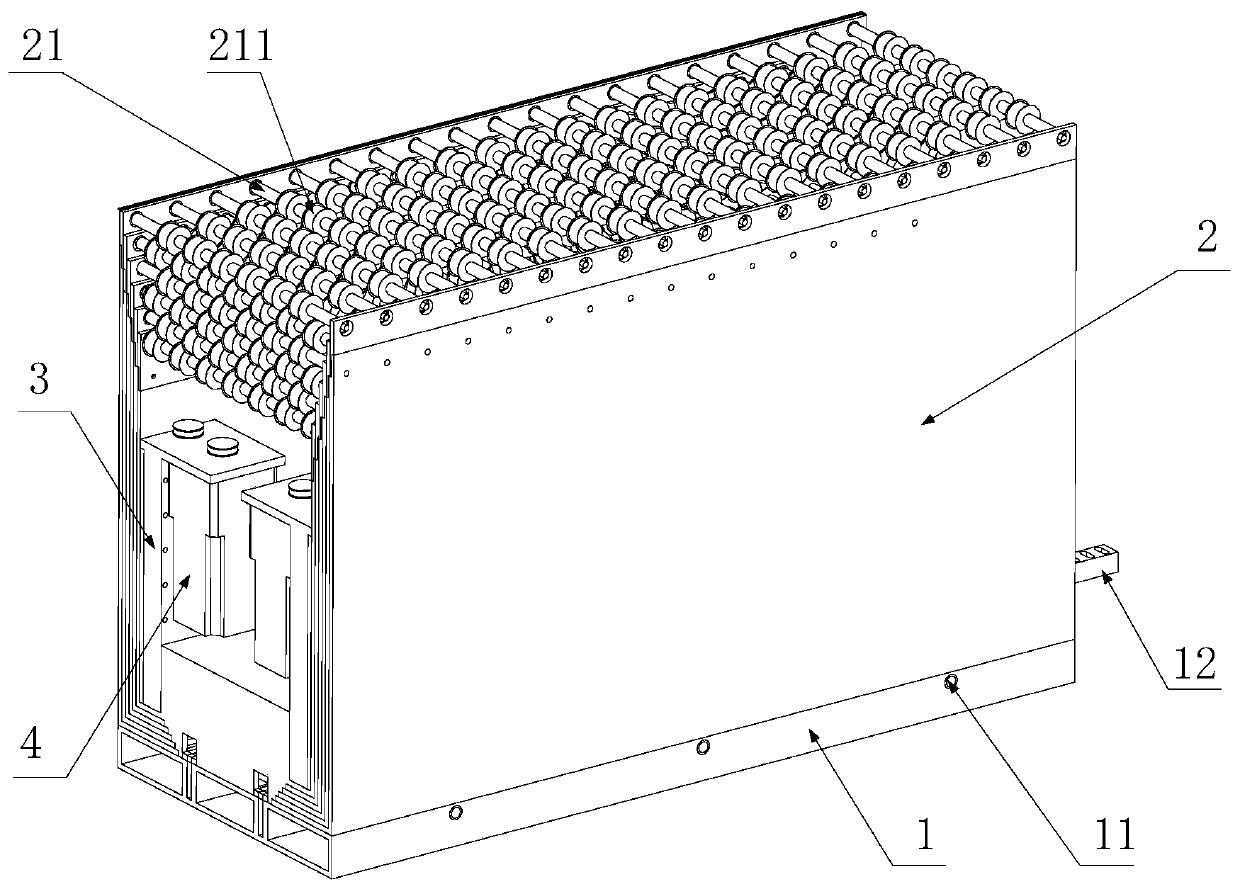

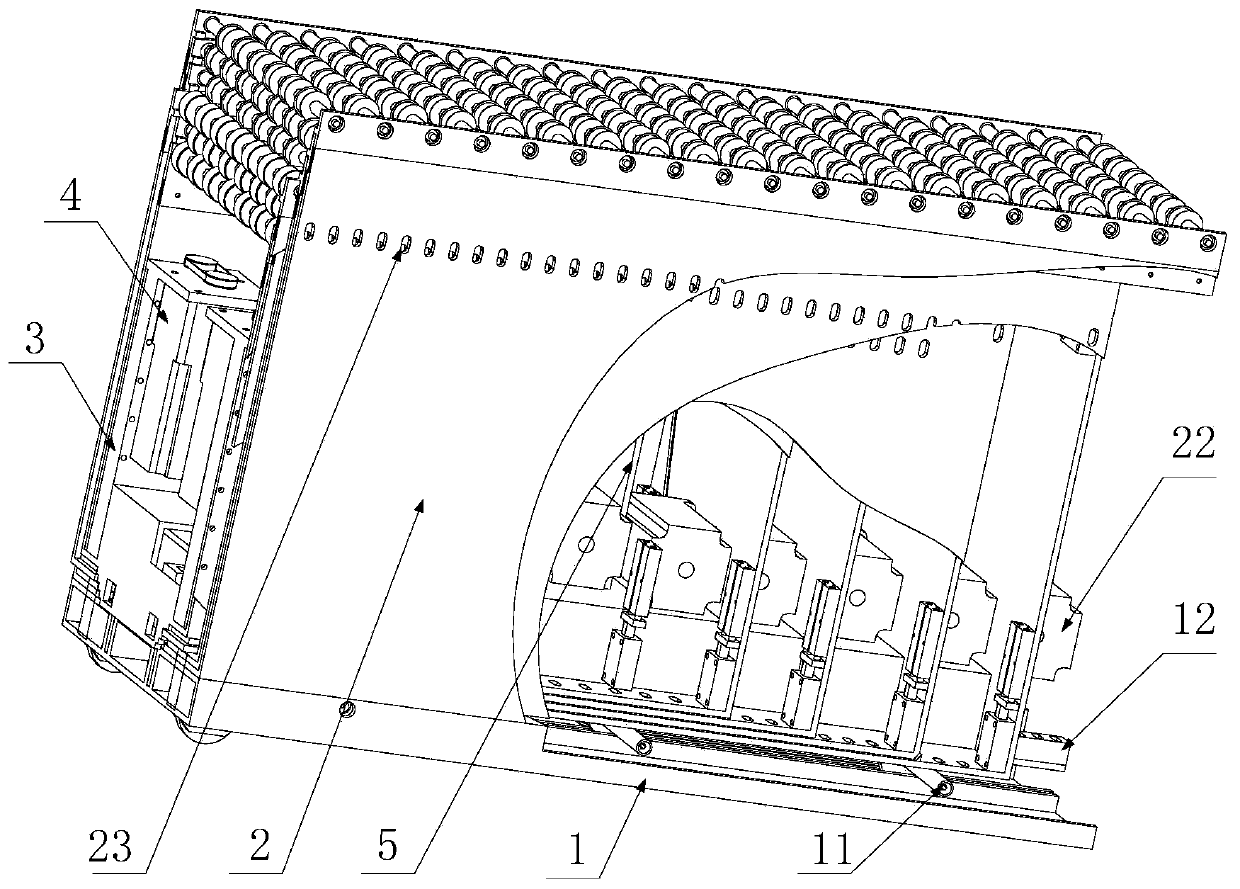

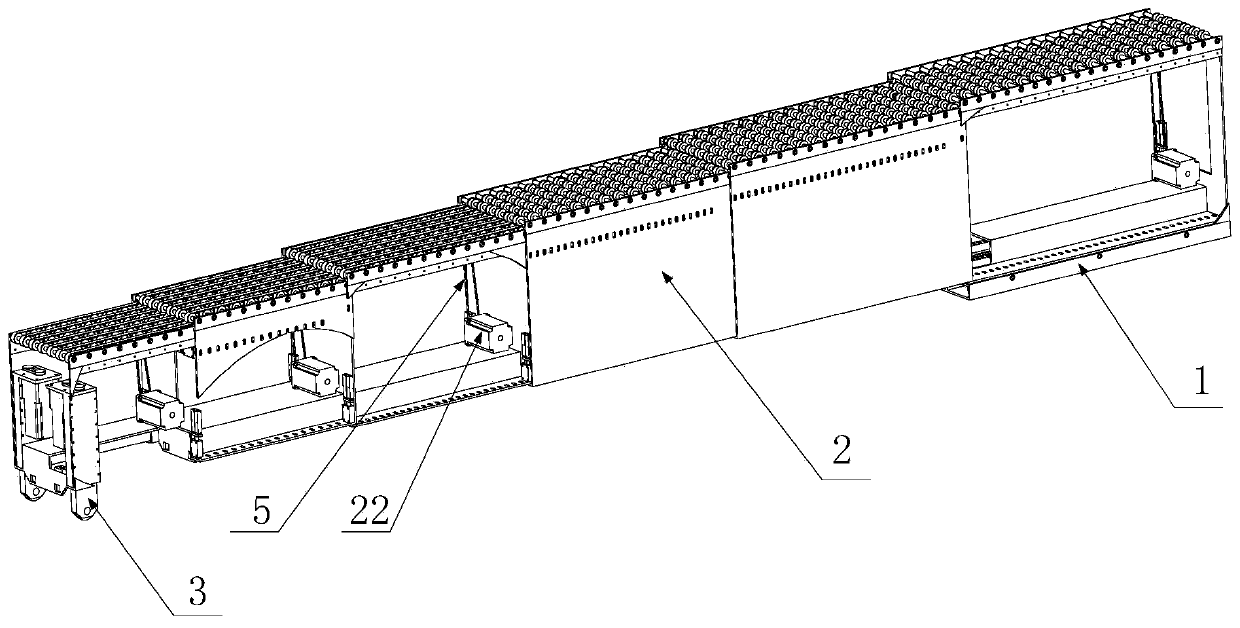

[0039] see Figure 1 ~ Figure 3 , figure 1 It is a schematic diagram of the retracted state of the telescopic conveying device provided by the embodiment of the present invention, figure 2 is a partial cross-sectional view of the retractable conveying device provided by the embodiment of the present invention in a contracted state, image 3 It is a partial cross-sectional view of the telescopic transmission device provided by the embodiment of the present invention in an extended state. The telescopic transmission device provided by the embodiment of the present invention includes a machine base 1 and a plurality of telescopic joints 2, wherein the telescopic joints 2 are box-shaped and are nested together one by one, and the outermost telescopic joint 2 is located at the Above, and fixedly connected with the machine base 1, the machine b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com