Lifting device, fire fighting device and mechanical equipment thereof

A lifting device and cable mechanism technology, applied in the direction of cranes, hoisting devices, hoisting equipment braking devices, etc., can solve the problems of not installing fire cannons and other fire-fighting devices, unable to extinguish them in time, and limited cantilever length, etc., to achieve expansion The effect of fire-fighting operation range, improvement of lifting operation range, and high fire extinguishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

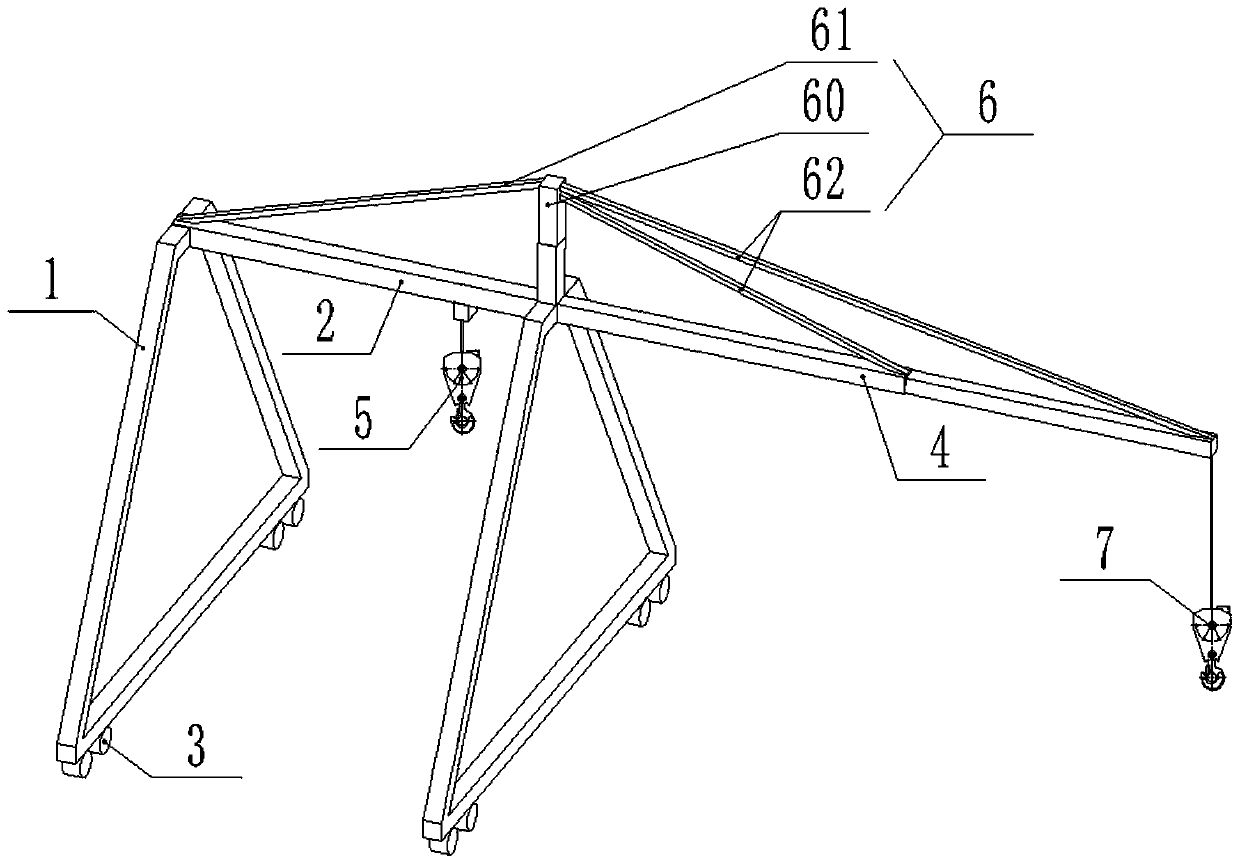

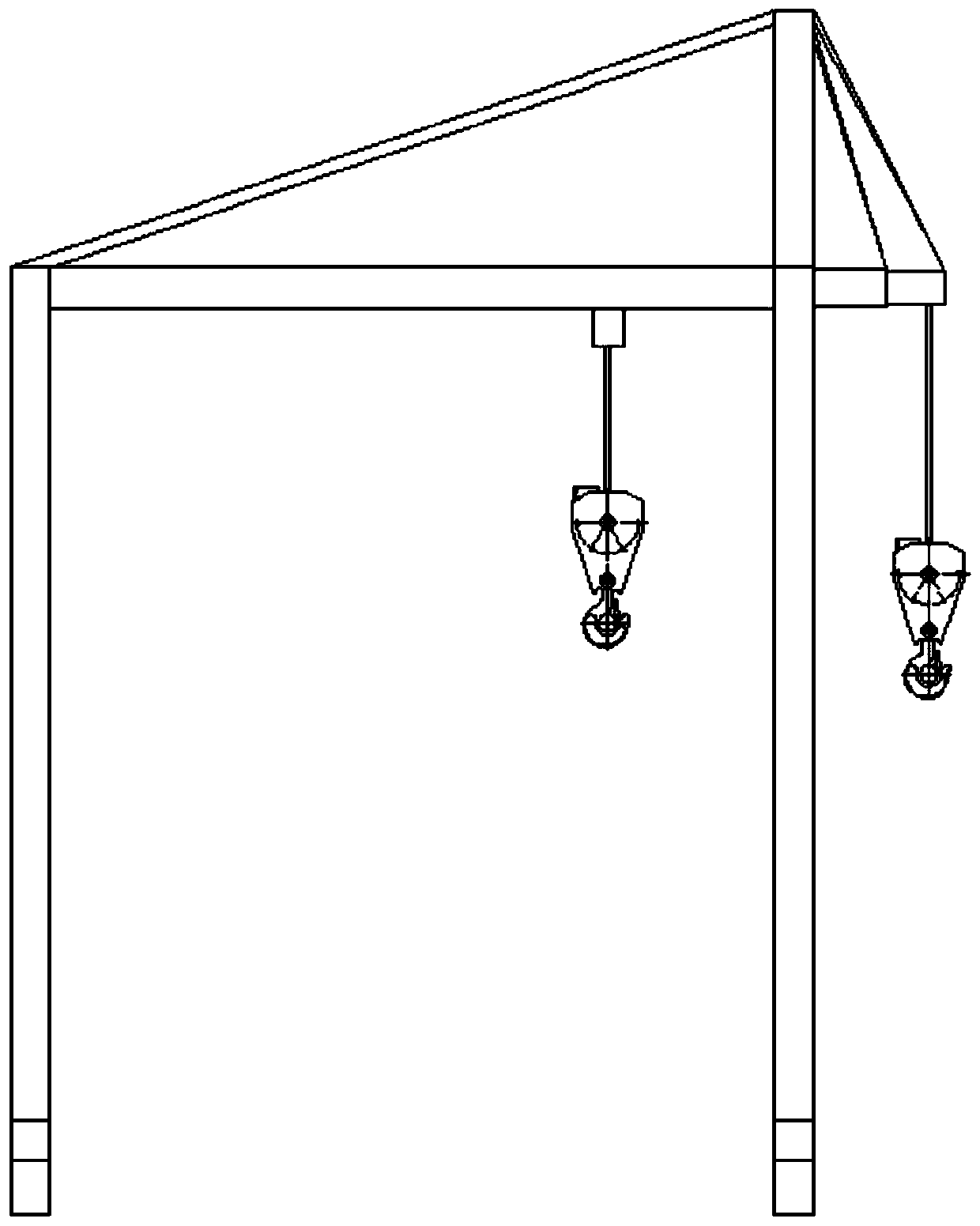

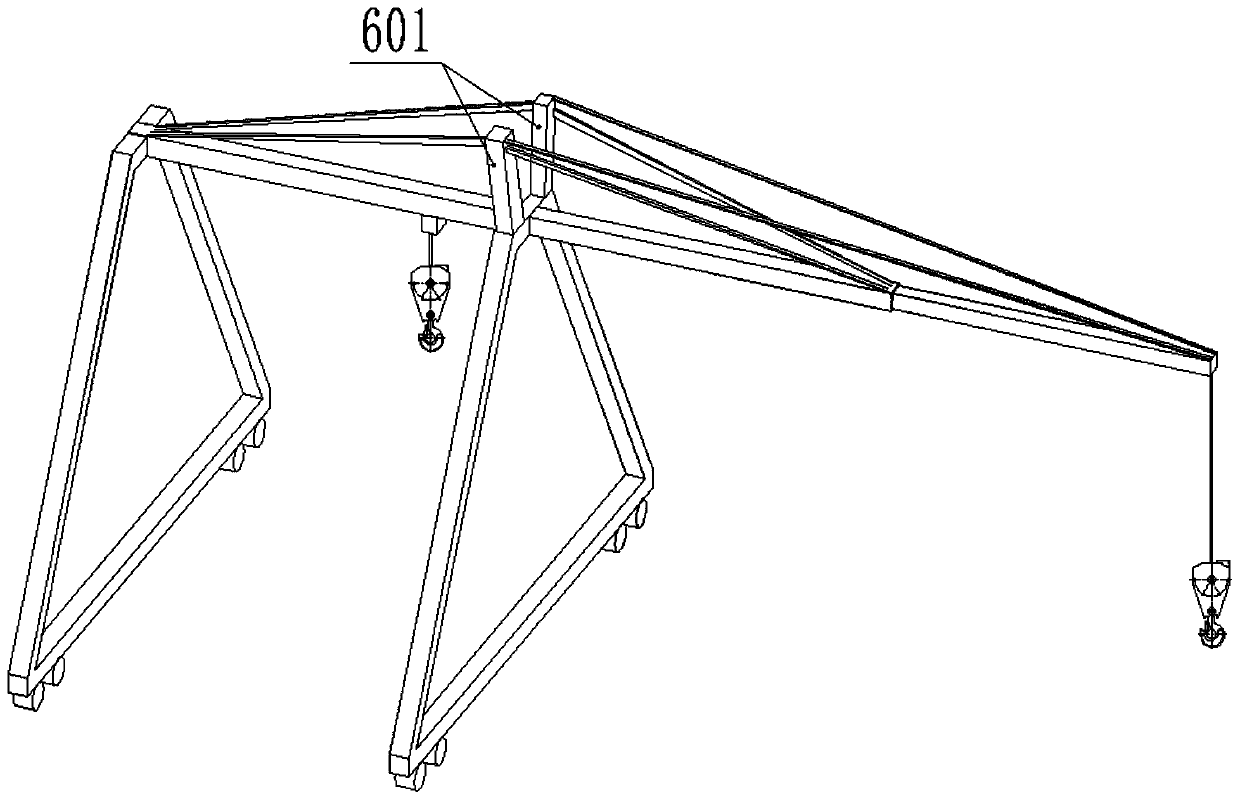

[0021] Such as Figure 1-3 As shown, a lifting device provided in this embodiment includes a beam 2, a pillar 1 and a walking mechanism 3, the two ends of the beam 2 are connected with the pillar 1; the bottom of the pillar 1 is connected with the Walking mechanism 3; described hoisting device also comprises cantilever telescoping mechanism 4, super-lifting cable mechanism 6 and mobile hoisting mechanism 5; Described cantilever telescoping mechanism 4 is located in described crossbeam 2, and Can be retracted and extended, the cantilever telescopic mechanism 4 is connected to the pillar 1 through the super-lifting cable mechanism 6; When hoisting, the mobile hoisting mechanism 5 moves along the crossbeam 2 or the cantilever telescopic mechanism 4 moves, thereby realizing hoisting in place at different working positions.

[0022] In this embodiment, on the basis of the traditional gantry crane, a cantilever telescopic mechanism 4 is added in the beam 2. The cantilever telescopi...

Embodiment 2

[0032] Embodiment 2 On the basis of Embodiment 1, further, a fire-fighting mechanism (not shown in the figure) is connected to the cantilever telescopic mechanism 4 . Under the action of the fire-fighting mechanism, the function of fire-fighting and fire-extinguishing can be realized, and the practicability of this embodiment can be improved. And under the effect of the cantilever telescopic mechanism 4, the fire-fighting operation range of the fire-fighting mechanism is expanded, and the fire-extinguishing efficiency is high. In this embodiment, the fire-fighting mechanism includes a fire-fighting monitor and a pipeline connected with the fire-fighting monitor, which can be selected from existing products, wherein the number of fire-fighting monitors is one or more, and multiple fire-fighting monitors are respectively arranged on the cantilever telescopic mechanism 4 Proper location to improve fire extinguishing efficiency. Wherein the fire-fighting mechanism requires that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com