Novel cap screwing machine

A capping machine and a new type of technology, applied in screw caps and other directions, can solve the problems of the bottle not being capped, the guide plate is bumpy, the bottle is broken, etc. falling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

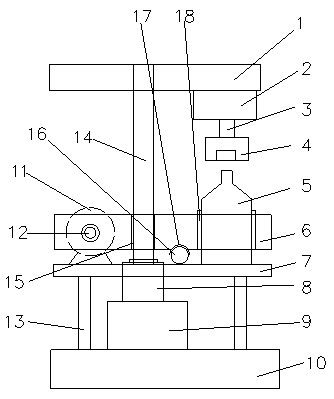

[0009] Such as figure 1 As shown, the new capping machine includes a base 10, the base 10 is connected to the guide plate 7 through the column 13; the base 10 is provided with a lifting cylinder 9, and the lifting cylinder 9 is connected to the telescopic rod 14 through the telescopic sleeve 8; the telescopic sleeve 8 passes through the guide plate 7, two The upper end face of the person is flush; the telescopic rod 14 passes through the bearing 15 located on the rotating plate 6; one end of the rotating plate 6 is fixedly connected with the telescopic rod 12 of the electric telescopic rod 11; the other end is provided with a ball 16; One end of the guide plate 7, the other end of the guide plate 7 places the bottle 5; the top of the bottle 5 is provided with a screw cap 4, the screw cap 4 is connected with the motor 2 through the connecting shaft 3, the motor 2 is fixed on the support plate 1, and the support plate 1 is fixed with the telescopic rod 14 connect.

[0010] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com