Multi-core direct-insert electric connection structure for while-drilling instrument

A technology of electrical connection structure and instrument while drilling, which is applied in the direction of connection, two-part connection device, parts of connection device, etc. It can solve the problems of blind insertion, poor anti-vibration performance, long axial dimension, etc., and achieve The effect of simple structure, good anti-vibration performance and short axial dimension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

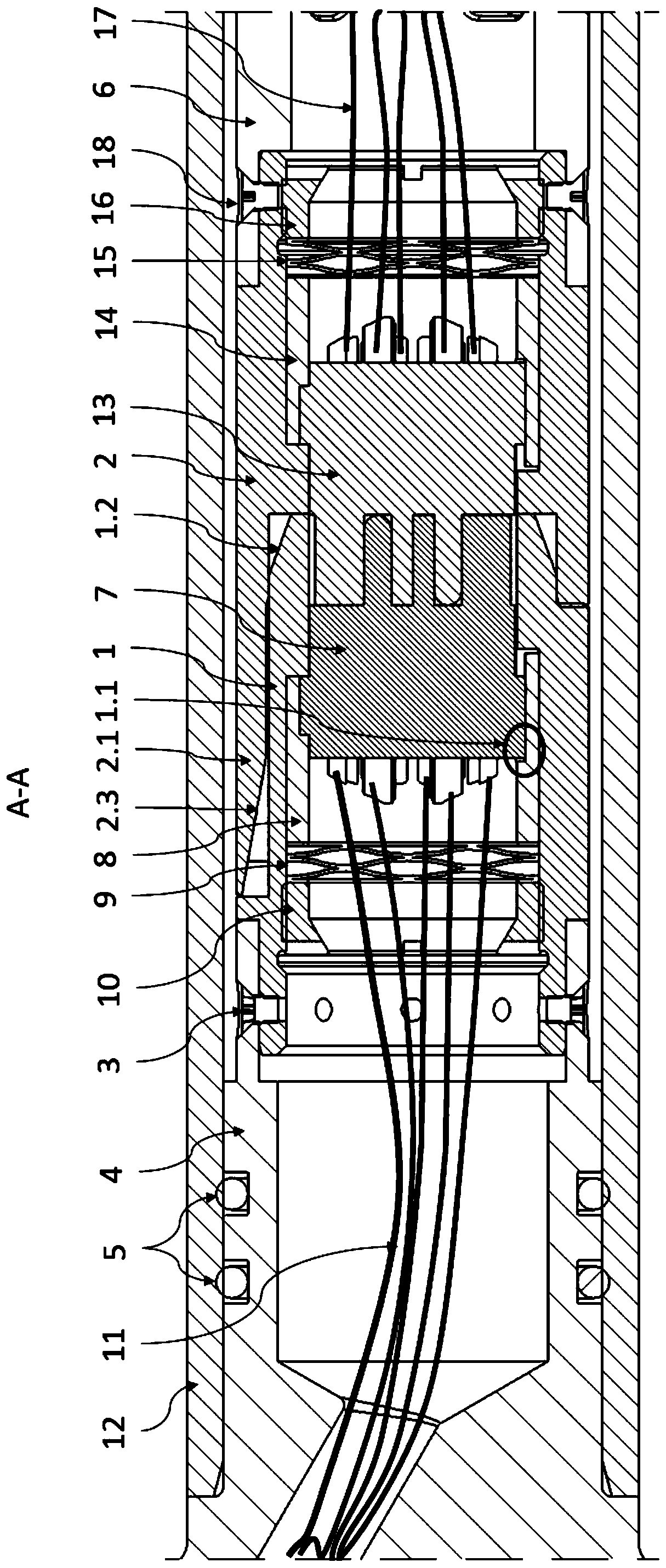

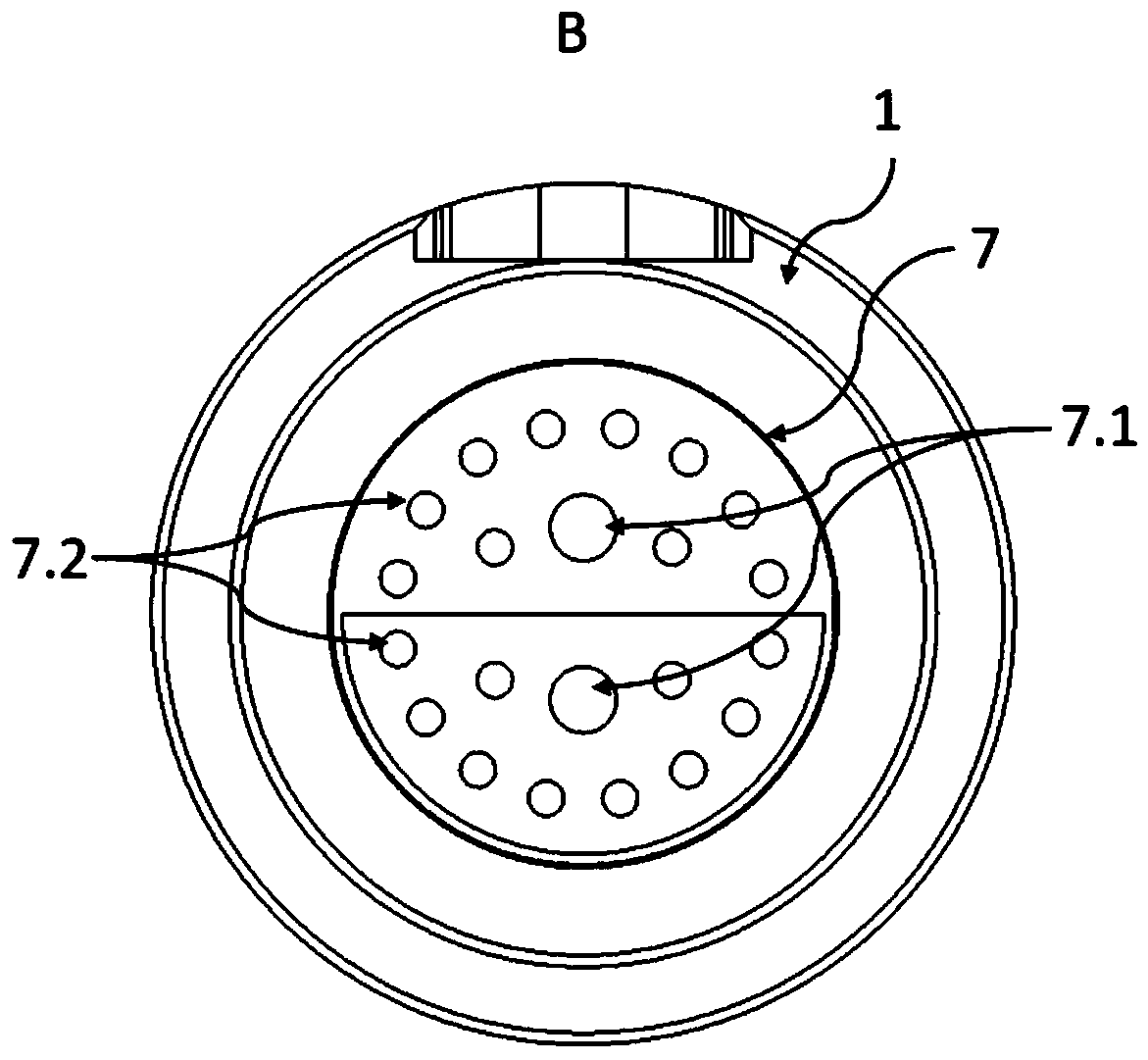

[0026] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

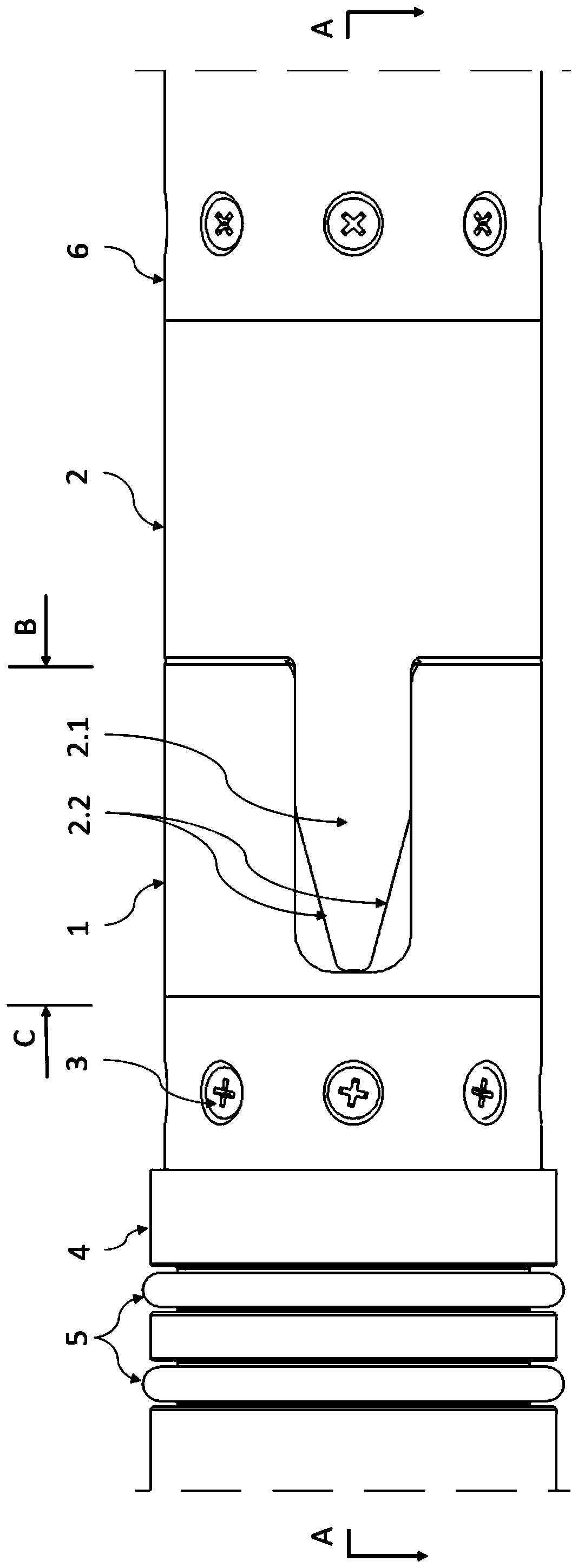

[0027] Such as Figure 1-Figure 4 As shown, the present invention is a multi-core in-line electrical connection structure for a tool while drilling. The connecting end of the second drilling tool has a plug shell with a guiding function; the socket shell is provided with a socket inner core with a buffering effect; the plug shell is provided with a plug inner core with a buffering effect.

[0028] According to an embodiment of the present disclosure, the multi-core in-line electrical connection structure further includes a pressure-resistant shell for protecting the multi-core in-line electrical connection structure, and the pressure-resistant shell is sleeved on the entire in-line electrical connection structure On the outside, the two ends of the pressure-resistant shell are respectively sealed with the ends of the first instrument while dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com