Production method of alumina continuous fiber sheet and alumina continuous fiber sheet

A kind of aluminum oxide, continuous fiber technology, applied in the direction of non-woven fabrics, textiles and papermaking, artificial filaments of inorganic raw materials, etc., can solve the problems of honeycomb carrier damage, failure to relieve impact, insufficient holding force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

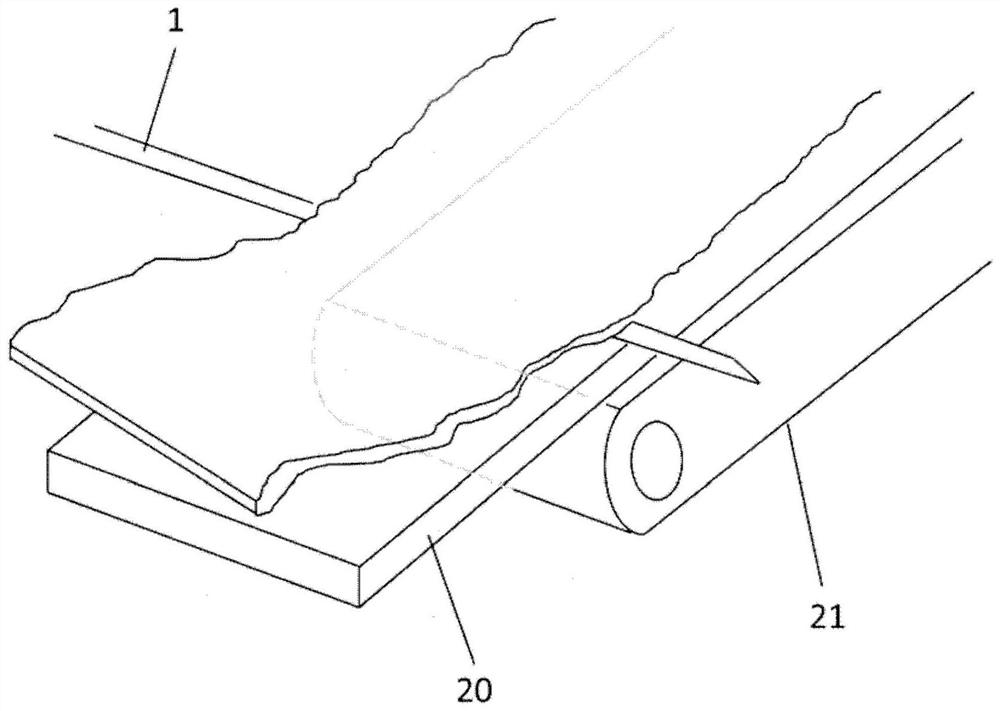

[0071] "Example 1"

[0072] Mixing an aluminum oxychloride aqueous solution with an alumina solid content concentration of 20.0 mass % and a silica colloid with a silica concentration of 20.0 mass % so that the alumina content is 73 mass % and the silica content is 27 mass %; Further, a partially saponified polyvinyl alcohol solution with a degree of polymerization of 1700 and a solid content concentration of 10% was mixed so that the total solid content of the alumina component and the silica component was 8%; thereafter, dehydration and concentration under reduced pressure were carried out, A spinning dope with a viscosity of 2000 mPa·s was produced.

[0073]This spinning dope is provided to a hollow disk with a diameter of 350mmφ, and 300 fine holes with a diameter of 0.2mm are opened at equal intervals on the circumference of the disk, so as to be sprayed out with a discharge amount of 25mL / h per hole. The disk was rotated at a peripheral speed of 47.6 m / sec, whereby the ...

Embodiment 2、3

[0089] "Example 2, 3"

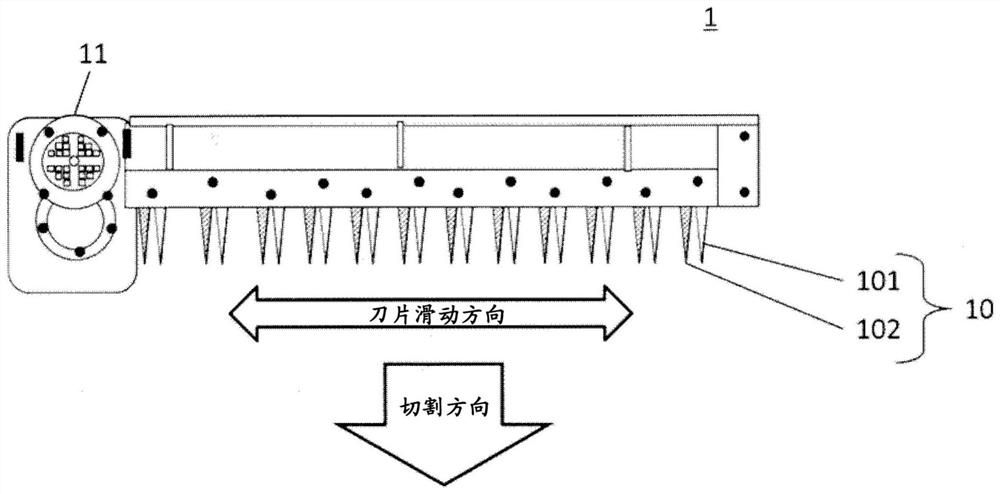

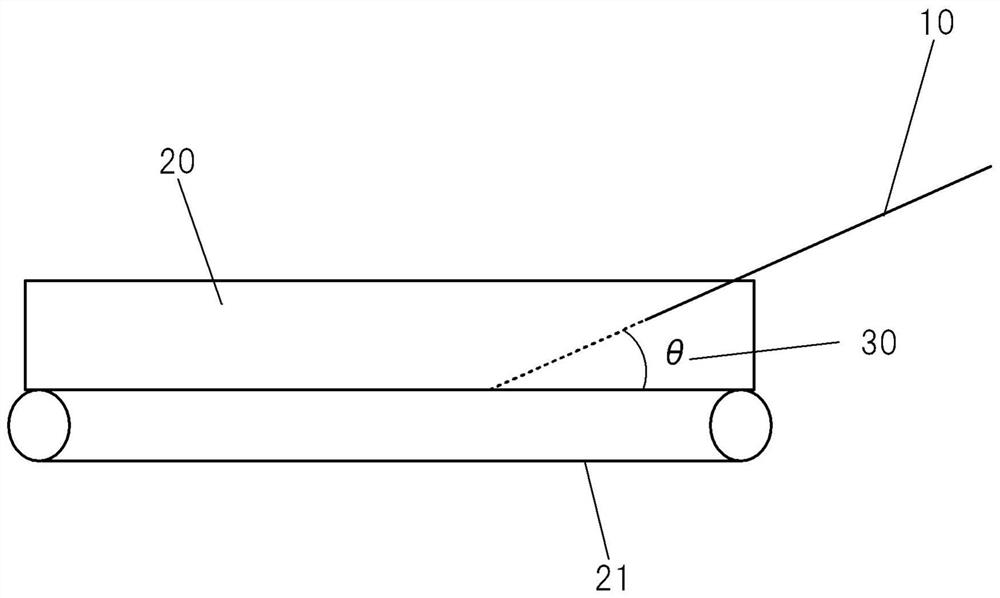

[0090] An alumina-based continuous fiber sheet was produced in the same manner as in Example 1 except that the type of slicer was changed. The slicer used is as follows.

Embodiment 2

[0091] Example 2: Band saw slicer (slicer that rotates a ribbon blade at high speed)

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap