Rust-proof oil coating equipment for maintenance of injection mold capable of wiping sundries

A technology of injection mold and anti-rust oil, which is applied in coating, device for coating liquid on the surface, spray device, etc., can solve the problems of difficult to wipe clean, many gaps, and high rejection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions in the embodiments of the present invention will be further clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

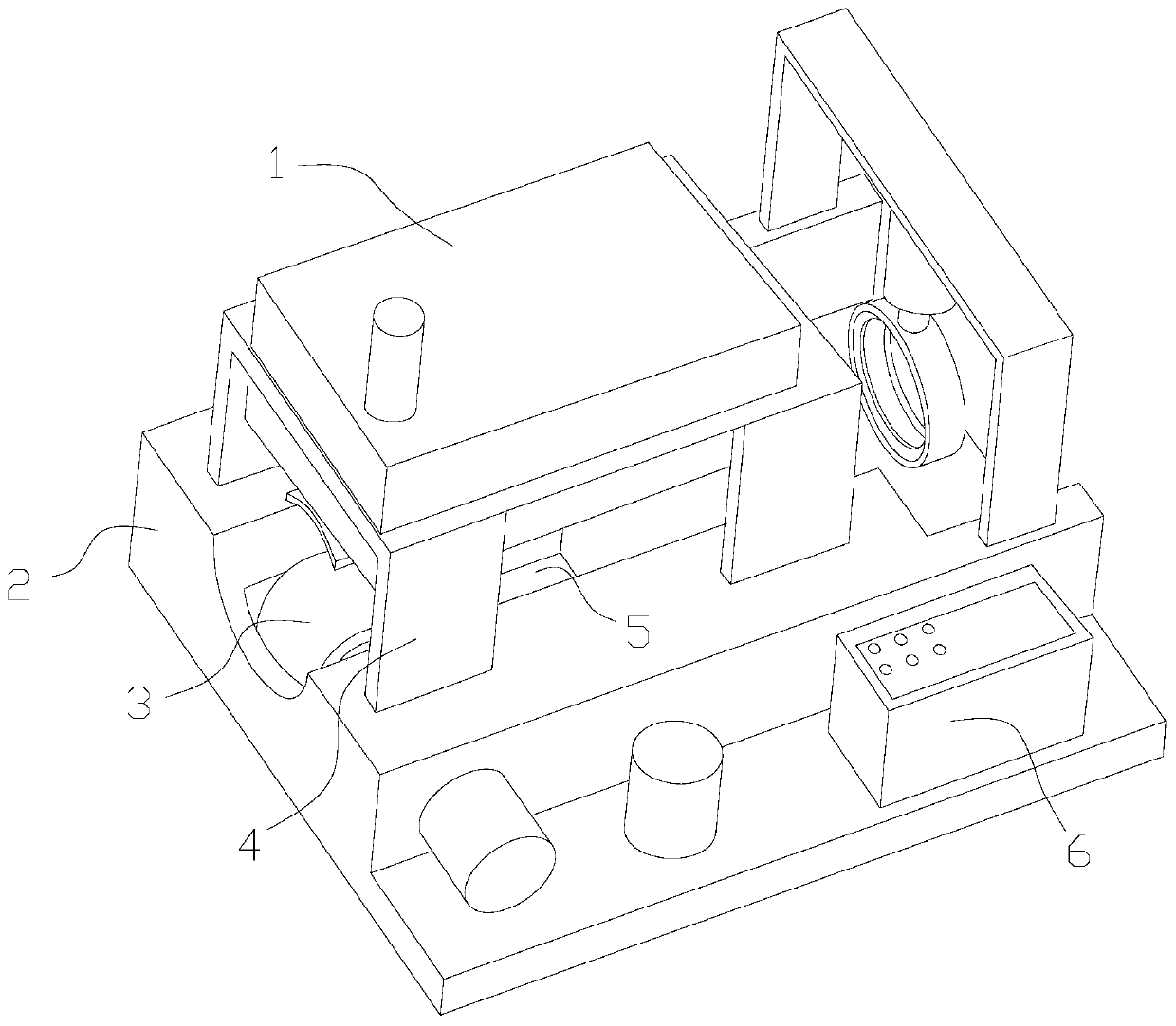

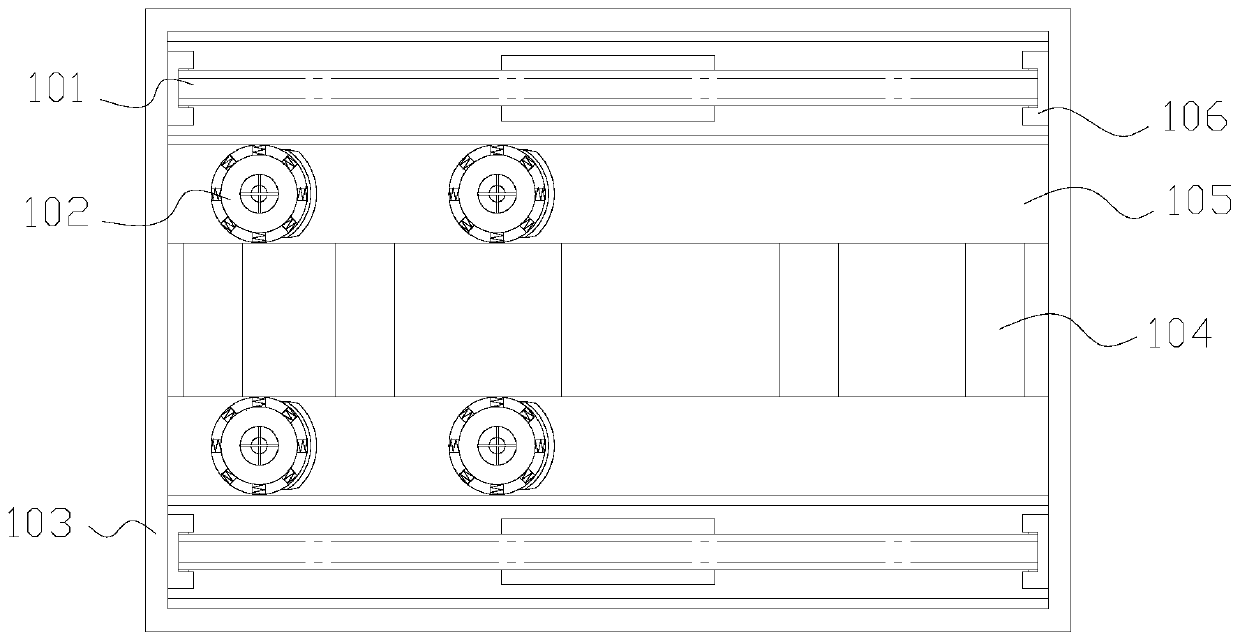

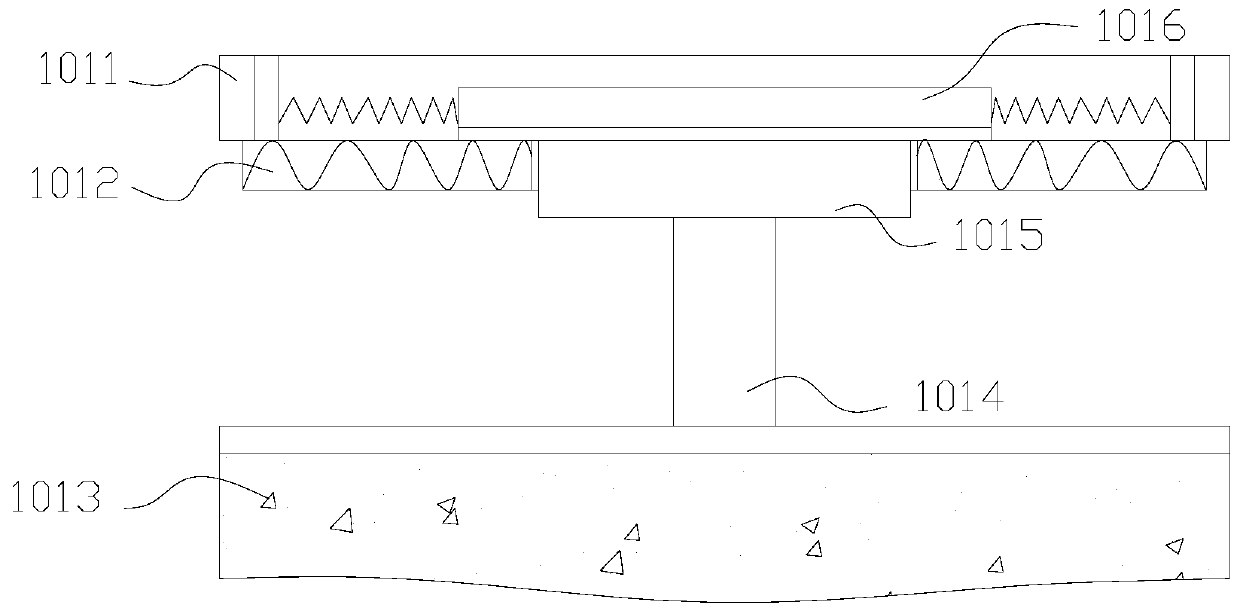

[0023] see Figure 1-Figure 5 , the present invention provides antirust oil smearing equipment for injection mold maintenance that can wipe debris: its structure includes a wiping device 1, a base 2, a rolling shaft 3, a support table 4, a placement groove 5, and a controller 6, and is characterized in that:

[0024] The wiping device 1 is embedded and installed on the top of the support table 4 and the bottom is located directly above the placement groove 5. A placement groove 5 is installed at a third of the rear side of the top outer surface of the base 2, and the rolling shaft 3 is fixedly installed on the placement groove 5. The inner side of the groove 5 is fitted with clearance, the bottom of the support table 4 is welded to both sides of the top outer surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com