Vehicle front floor structure, aluminum alloy extrusion molding part and vehicle

A front floor and aluminum alloy technology, which is applied to vehicle components, upper structure sub-assemblies, upper structures, etc., can solve the problems of large threshold deformation and intrusion, light body strength, and insufficient height, so as to improve safety reliability and enhance strength , Strong adaptability and scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] First of all, it should be noted that the vehicle front floor structure, aluminum alloy extruded parts and the specific structure, composition, characteristics and advantages of the vehicle will be described in detail below by way of example, but all descriptions are for illustration only , and should not be construed as forming any limitation on the present invention.

[0018] In addition, unless otherwise specified in the text, various parts, components, features or devices involved in the technical solutions of the present invention are allowed to be combined arbitrarily to form more embodiments that may not be explicitly described herein. In addition, for the sake of simplifying the drawings, the same or similar parts and features may only be marked at one or several places in the same drawing.

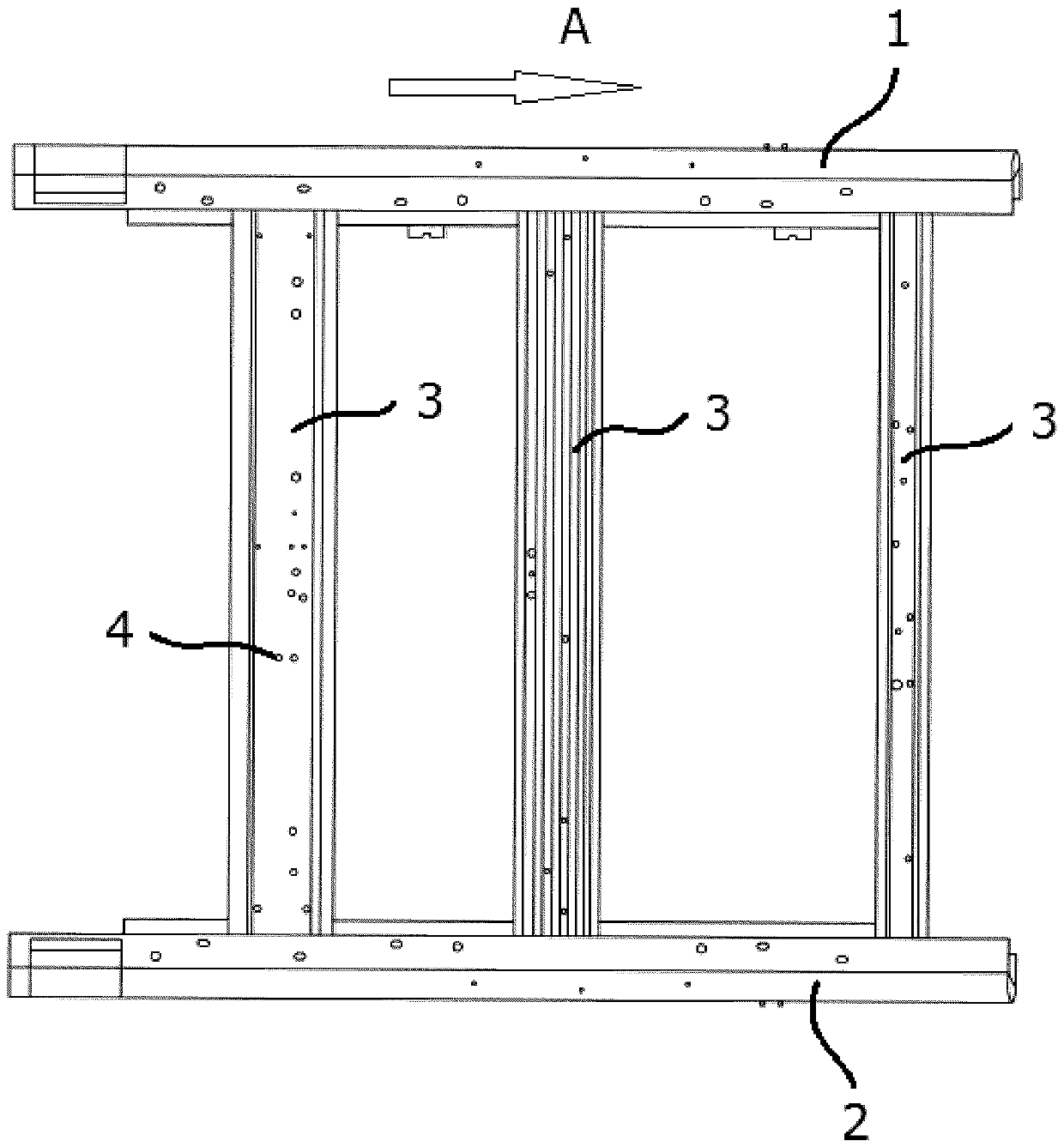

[0019] exist figure 1 The basic structure of an embodiment of the front floor structure of a vehicle is schematically and roughly illustrated in top view in . In this emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com