superstructure

A car body and vehicle technology, applied in the direction of upper structure, upper structure sub-assembly, vehicle parts, etc., can solve the problems of increasing weight, increasing cost, increasing car body weight, etc., to improve connection strength, suppress deformation, and suppress torsion deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

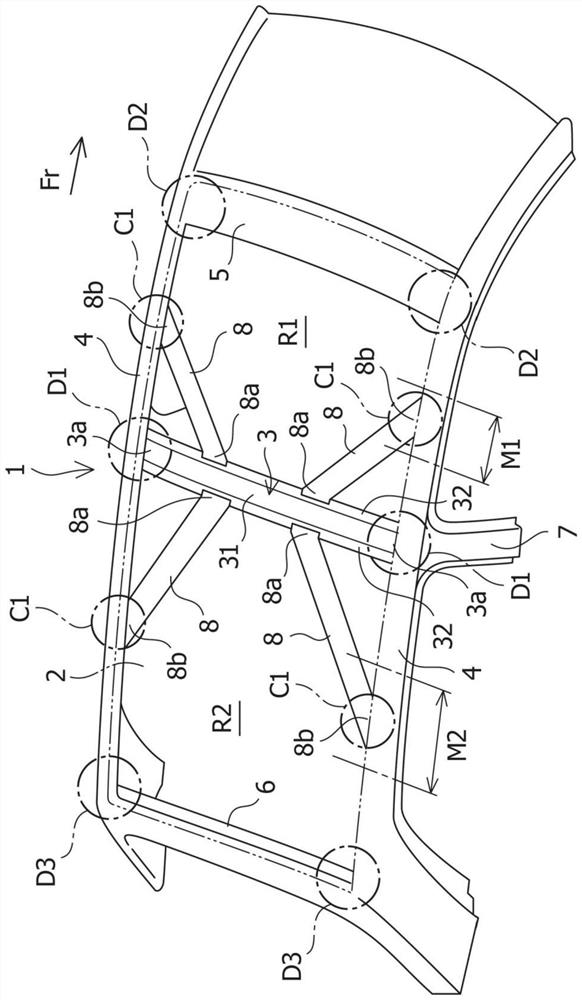

[0024] figure 1 A vehicle body superstructure according to a first embodiment of the present invention is shown.

[0025] like figure 1 As shown, the vehicle body upper part 1 of the vehicle to which the structure according to the first embodiment of the present invention is applied mainly includes a resin roof 2, a roof cross member 3 extending in the vehicle width direction, a Roof rails 4 extending on the left and right sides of the vehicle body, and roof front rails 5 and roof rear rails 6 extending in the vehicle width direction at front and rear end portions of the vehicle body, respectively. The resin roof 2 is a resin plate or the like for reducing the weight of the vehicle body. The resin roof 2 is the peripheral parts of the roof rails 4 located on the left and right sides of the vehicle body upper part 1 and the roof front beams 5 and roof rear beams 6 respectively located at the front and rear end parts of the vehicle body upper part 1, and the resin vehicle The...

no. 2 approach

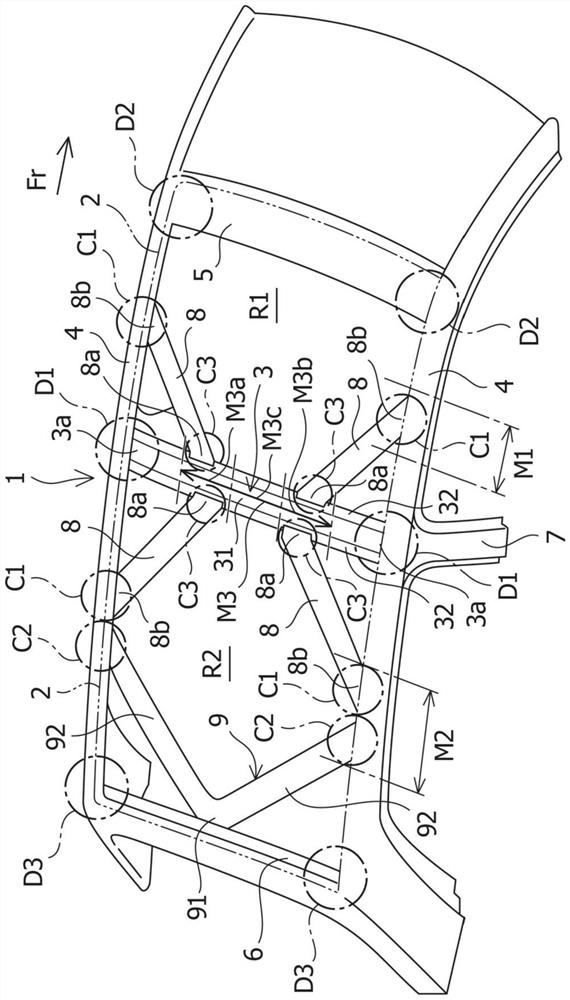

[0035] figure 2 A vehicle body superstructure according to a second embodiment of the present invention is shown. The same parts as those explained in the above-mentioned first embodiment are denoted by the same reference numerals, and repeated description thereof is omitted.

[0036] In the vehicle body upper part 1 according to the second embodiment, in addition to the structure according to the first embodiment, as figure 2 As shown, a second reinforcing member 9 is arranged in the vehicle rear side region R2 to connect the roof rear rail 6 to the respective roof rails 4 located on the left and right sides. The second reinforcement member 9 includes: a beam joint portion 91 at which the second reinforcement member 9 is joined to the roof rear rail 6 ; and a side member joint portion 92 at which the second reinforcement member 9 is branched. While extending toward the front of the vehicle along the oblique direction and extending to a corresponding one of the roof rails ...

no. 3 approach

[0039] figure 1 A vehicle body superstructure according to a third embodiment of the present invention is shown. The same parts as those explained in the above-mentioned first embodiment are denoted by the same reference numerals, and repeated description thereof is omitted.

[0040] In the vehicle front side region R1 of the vehicle body upper portion 1 according to the third embodiment, in addition to the structure according to the first embodiment, as figure 1 As shown, the connection portion C1 between the roof rail 4 and the first reinforcement member 8 is arranged in the middle area in the thirdly divided area in the vehicle front-rear direction between the roof rail 3 and the roof front rail 5 . M1. Furthermore, in the vehicle rear side region R2 of the vehicle body upper portion 1 , the connecting portion C1 between the roof rail 4 and the first reinforcement member 8 is arranged such that the connecting portion C1 is located between the roof rail 3 and the roof rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com