Material-jamming preventing feeding hopper

A feeding hopper and anti-jam technology, applied in the field of injection molding, can solve the problems of silver streak, channel blockage, material jam, etc., and achieve good effect and reduce material blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

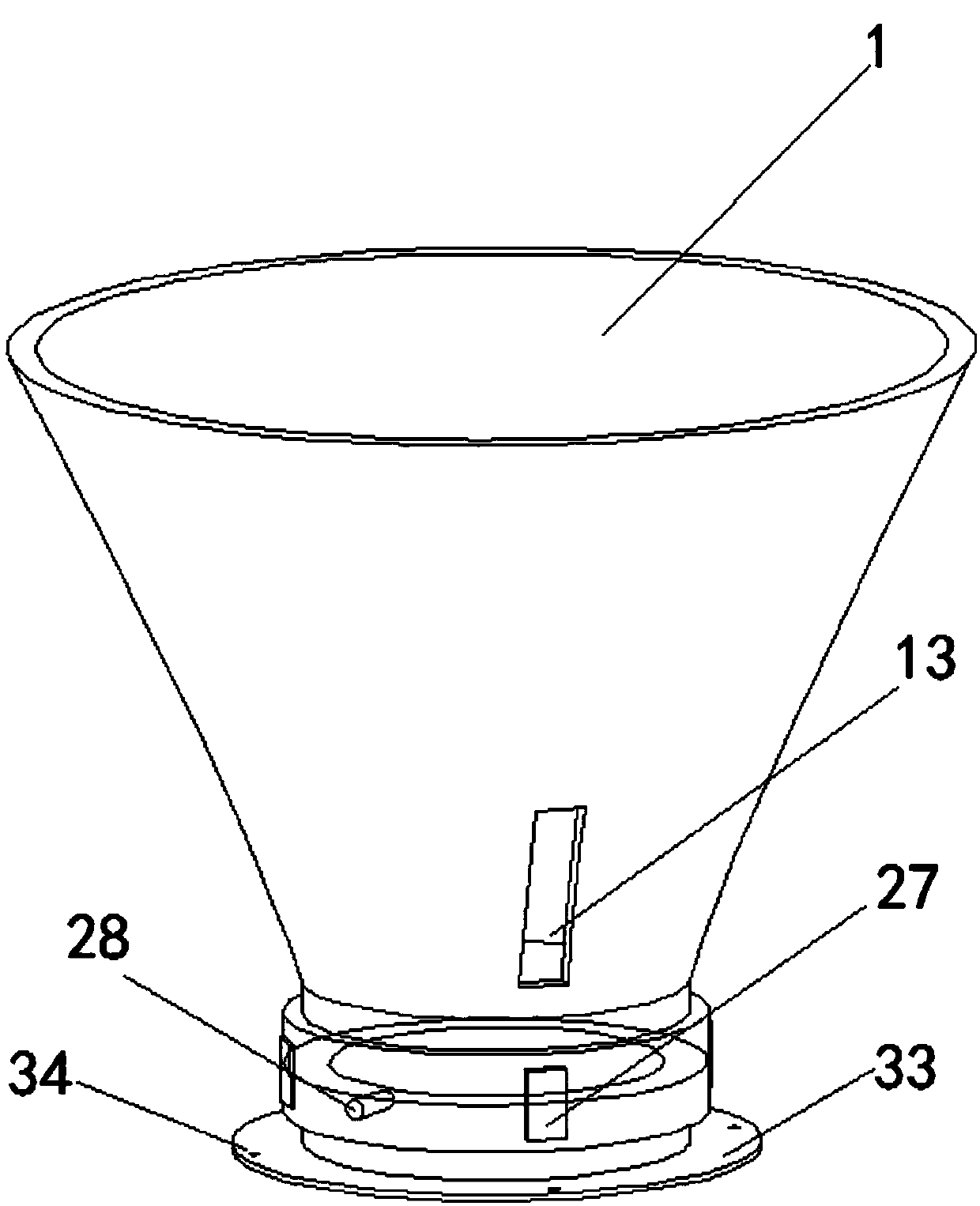

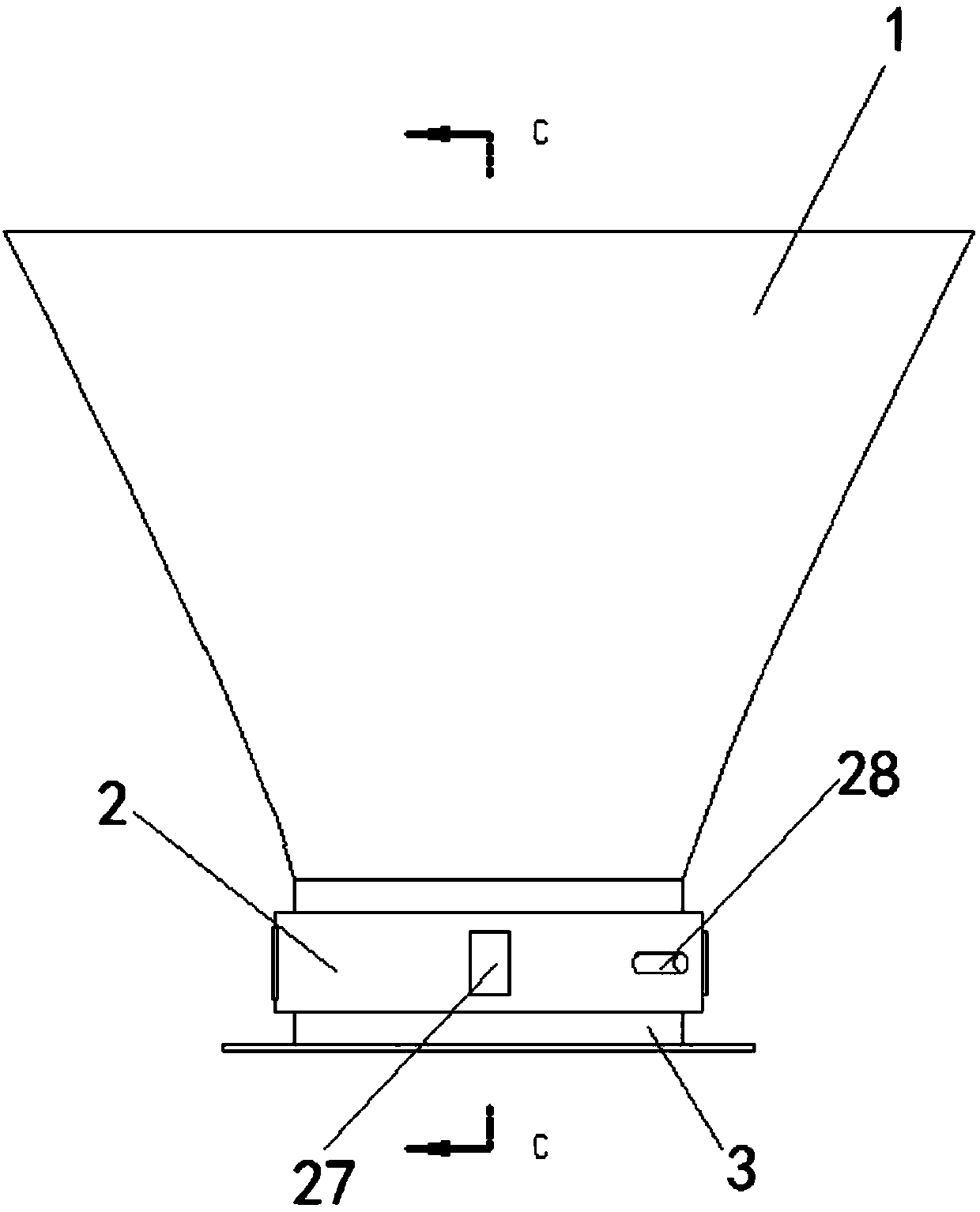

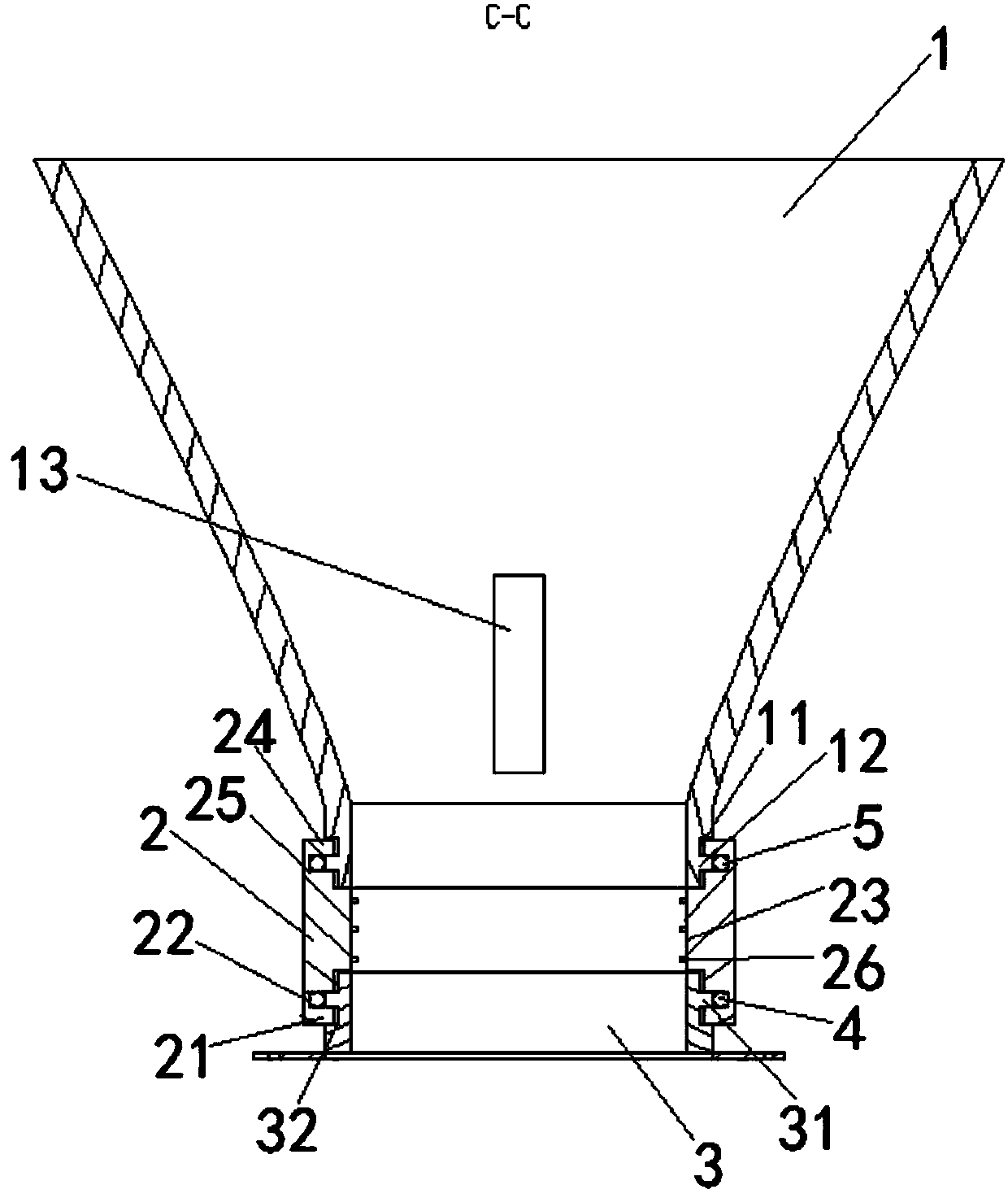

[0016] Embodiment 1: refer to Figure 1 to Figure 3 , an anti-jamming feed hopper, comprising a hopper body 1, a rotating ring 2 and a base 3, the hopper body 1 and the base 3 are connected through a rotatable rotating ring 2 located between the two, and the rotating ring 2 is provided with There are several vibration generators 27, several rotating rods 28 are arranged on the outer surface of the rotating ring 2, and granular protrusions 26 are uniformly arranged on the inner surface of the rotating ring 2.

[0017] Further, the lower part of the hopper body 1 is provided with an annular groove 11 and an annular protrusion 12, and the upper part of the rotating ring 2 is provided with an annular protrusion 24 corresponding to the annular groove 11 and an annular groove 25 corresponding to the annular protrusion 12. Between the protrusion 12 and the annular groove 25, several rotating beads 5 are arranged, the lower part of the rotating ring 2 is provided with an annular groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com