Clothes processing method

A technology for a clothing treatment device and a storage unit, which is applied to washing devices, other washing machines, textiles, and papermaking, etc., can solve the problems of scab cleaning, waste water discharge, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

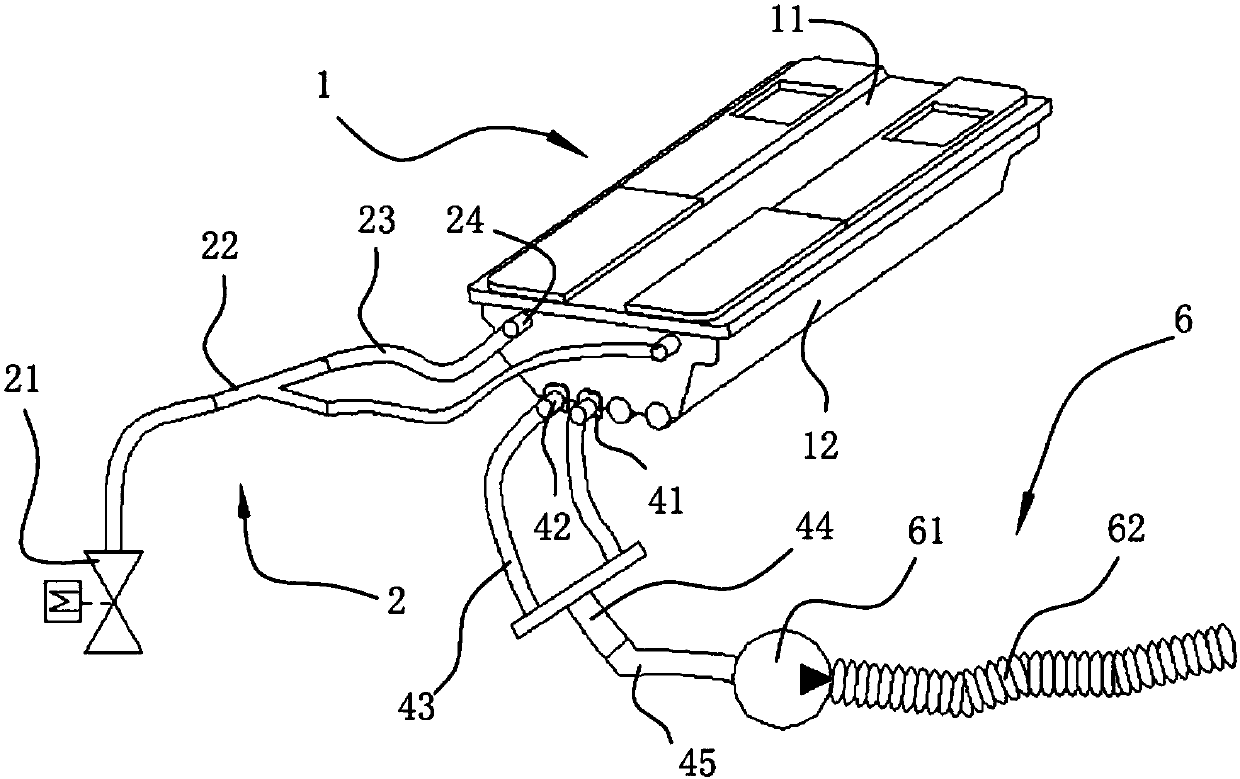

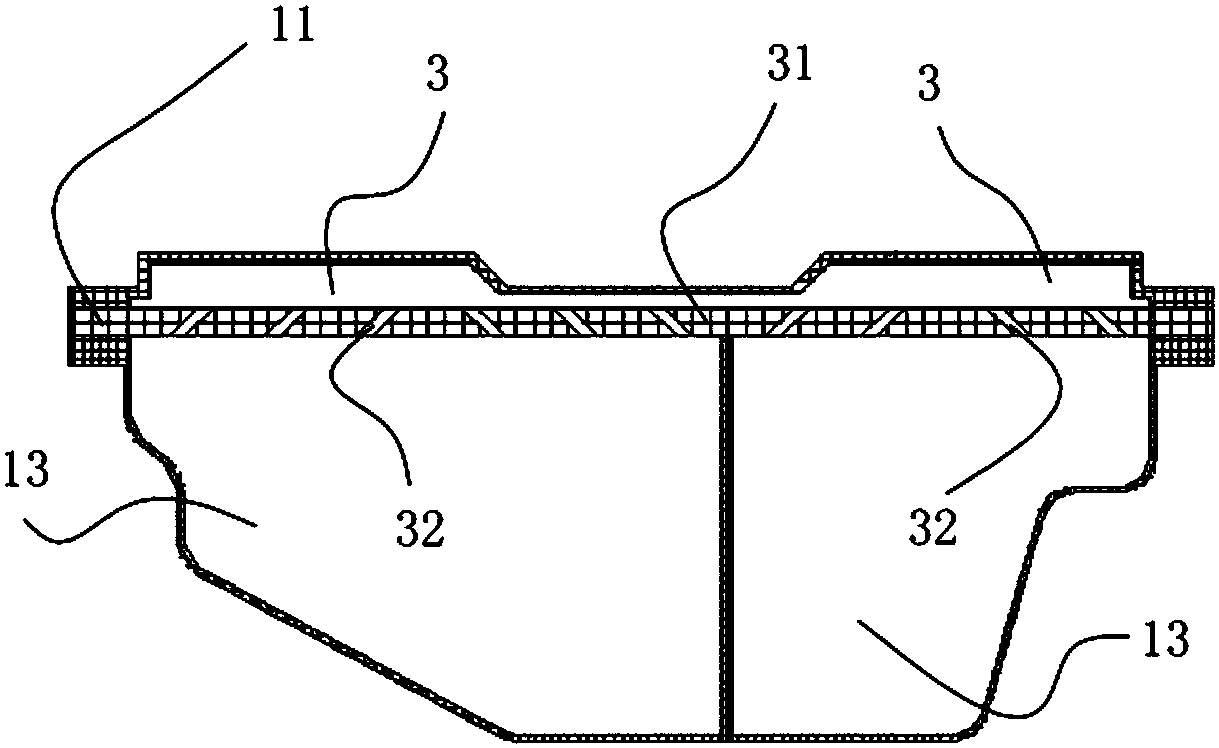

[0040] Such as figure 1 , figure 2 As shown, the clothes processing device described in this embodiment includes an automatic feeding device; the automatic feeding device includes a storage unit 1, a water inlet unit 2 communicated with the storage unit 1, and a liquid outlet unit; the storage unit 1 It includes a cover body 11 and a box body 12 that cooperate to form a storage chamber 13; the inside of the cover body 11 is a hollow spray chamber 3, and the cover body 11 is provided with a plurality of spraying chambers facing the spray side 31 of the storage chamber 13. Shower hole 32. The plurality of spray holes are respectively facing the side walls of the adjacent storage chambers. Further, there are two adjacent storage cavities, and the two storage cavities are separated by spacer ribs. Then the spray holes close to the spacer ribs face towards the side of the spacer ribs; the spray holes close to the walls around the storage cavity face towards the walls around the...

Embodiment 2

[0046] The difference between the laundry treatment device in this embodiment and the above-mentioned embodiments is that: the automatic feeding device further includes a feeding unit, and the feeding unit communicates with the storage unit for feeding additives into the laundry processing device. The automatic feeding device is in the washing process, and its working steps are that the feeding unit extracts the additive value from the storage unit into the feeding chamber of the feeding unit, and the water inlet device of the clothes treatment device injects water into the feeding chamber, thereby diluting the additive in the feeding chamber, and then The diluted additive is drained into the bucket along with water for washing clothes. The dosing unit in this embodiment draws the additive from the storage unit through the liquid outlet unit. That is, the feeding unit can draw out the liquid in the storage chamber through the liquid outlet unit, and discharge it into the cloth...

Embodiment 3

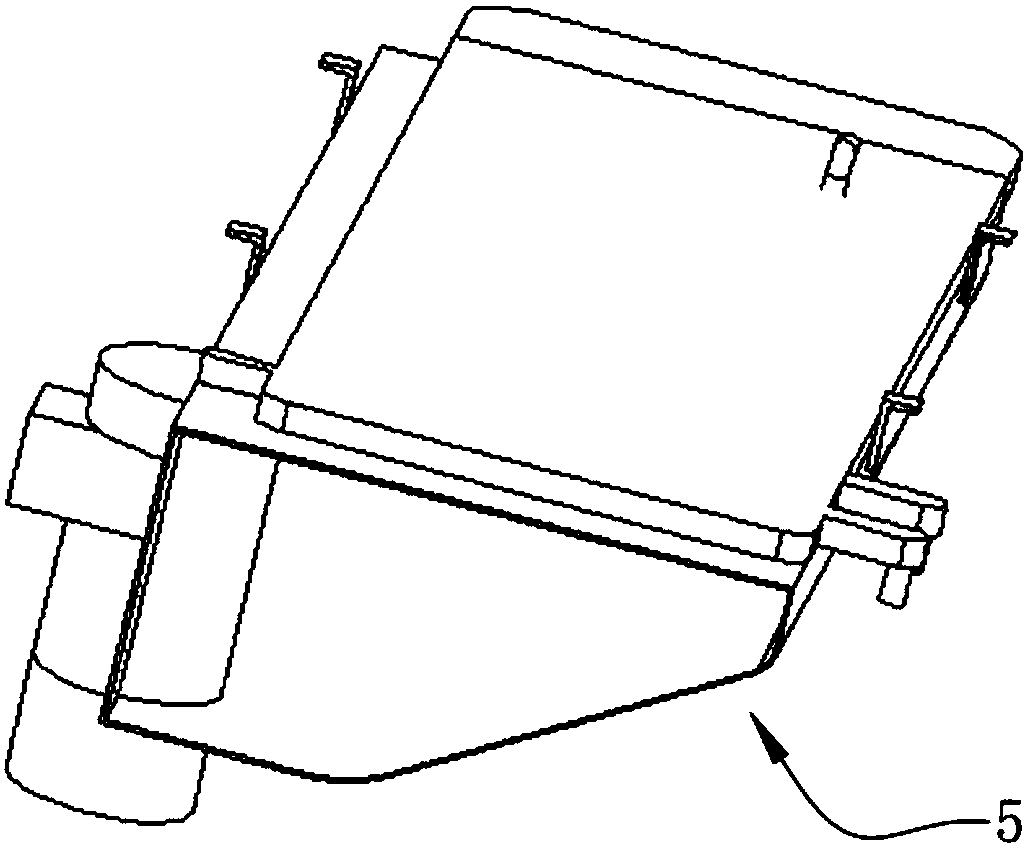

[0048] Such as image 3 As shown, the difference between the laundry treatment device described in this embodiment and the above embodiments is that: the automatic dispensing device is used for dispensing detergent; image 3 As shown, the clothes treatment device in this embodiment includes a housing 5 capable of setting the automatic dispensing device inside; the housing 5 can guide the water discharged from the liquid outlet unit into the clothes treatment device; further Specifically, the housing 5 can guide the water discharged from the liquid outlet unit into the inner bucket of the laundry treatment device, and then be discharged by the discharge mechanism. The structural complexity of the laundry treatment device can be reduced to a large extent.

[0049] In addition, when the washing program is running normally, water can also be fed through the automatic feeding device introduced in the present invention during the process of feeding the laundry treatment device. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com