Experimental device and method for assessing grain flow collective friction abrasion behavior

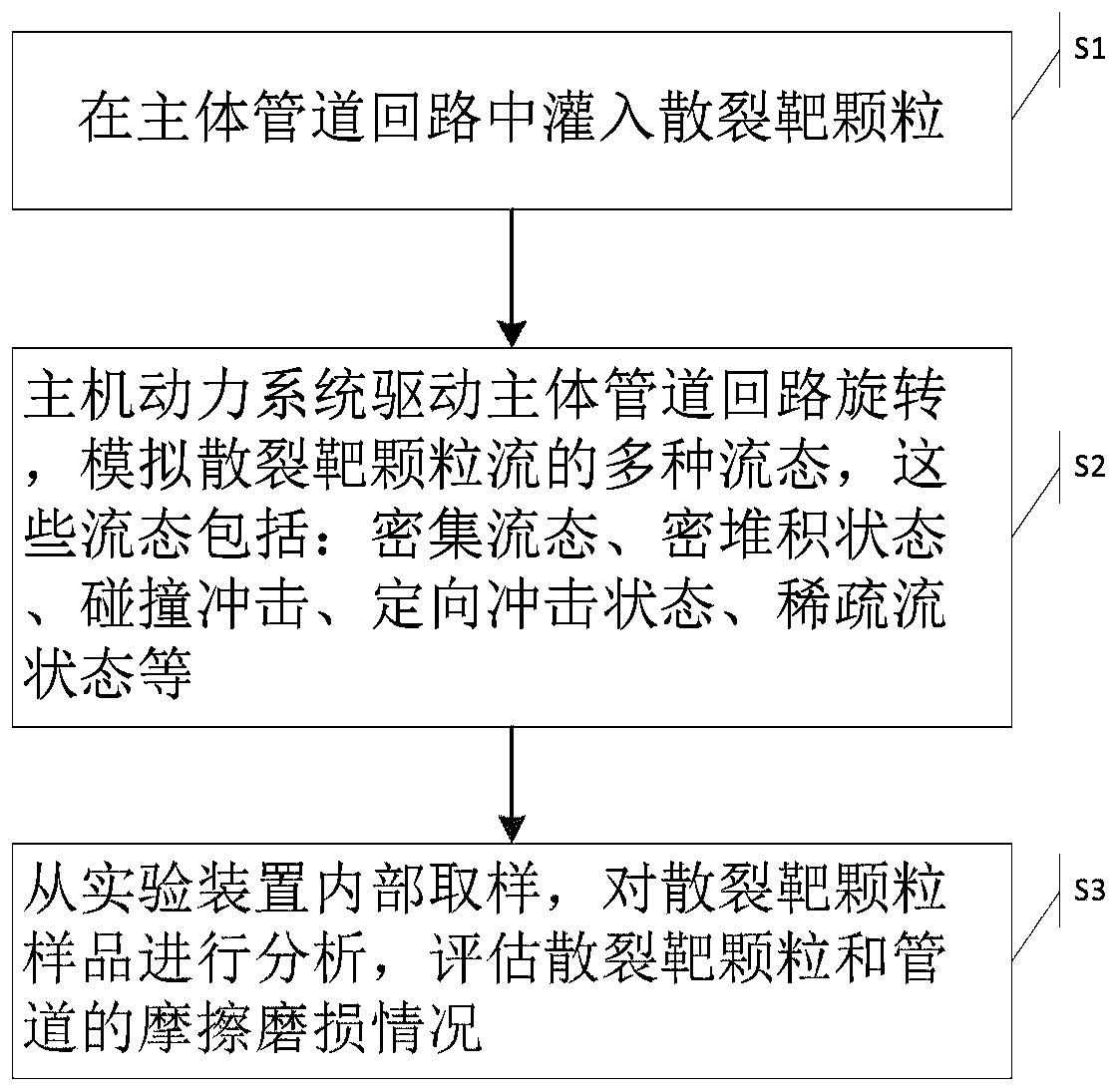

An experimental device and friction and wear technology, which is applied in the direction of testing wear resistance, etc., can solve problems such as single friction form, large differences in experimental conditions, discrete cracked target operating conditions, and collective friction and wear behavior of difficult particle targets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

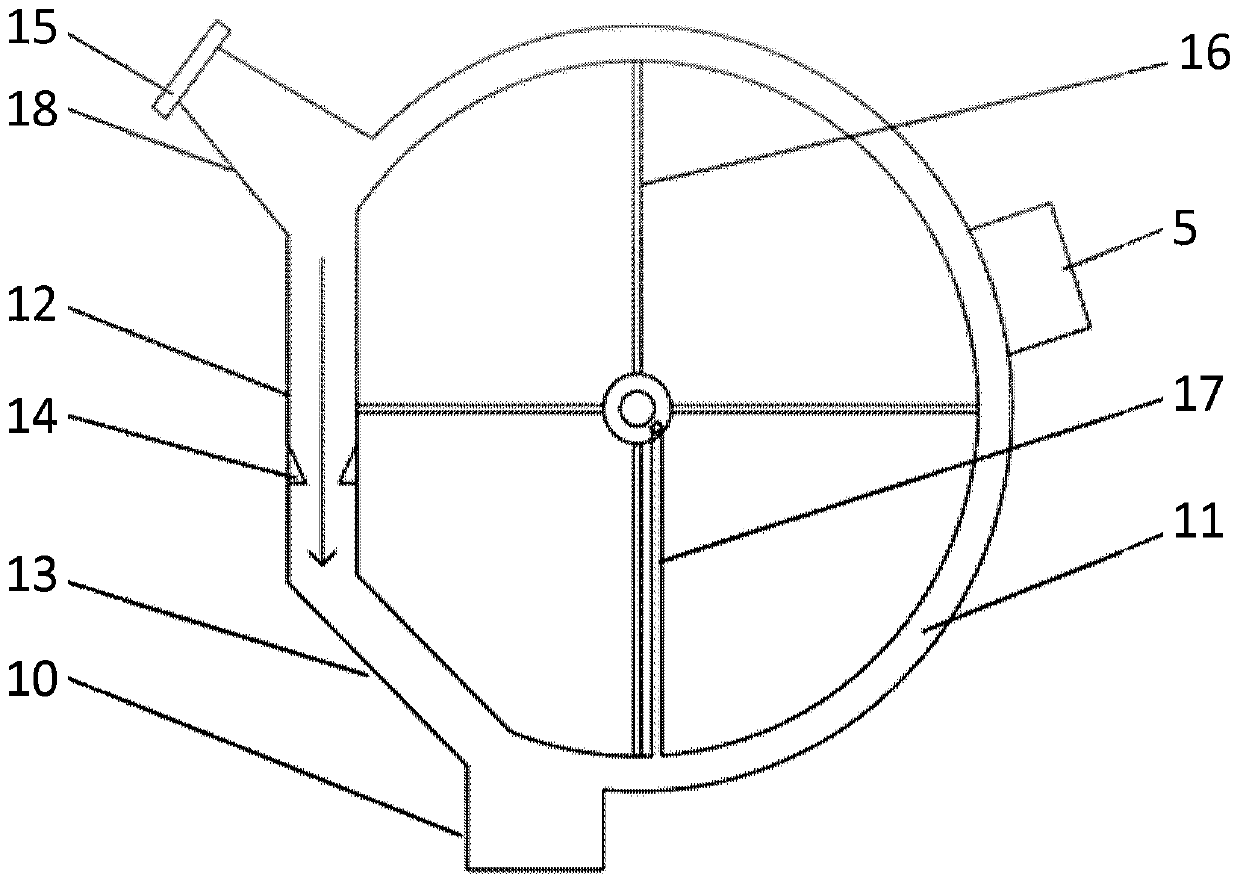

[0027] The disclosed device uses a motor to drive the pipeline to run to simulate the driving operation of the particles inside the spallation target. During operation, it can realize the complex movement of the particle flow, and can simulate the particle flow target to realize the temporary storage and flow of the target ball at different sections.

[0028] In order to make the purpose, technical solutions and advantages of the present disclosure clearer, the present disclosure will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

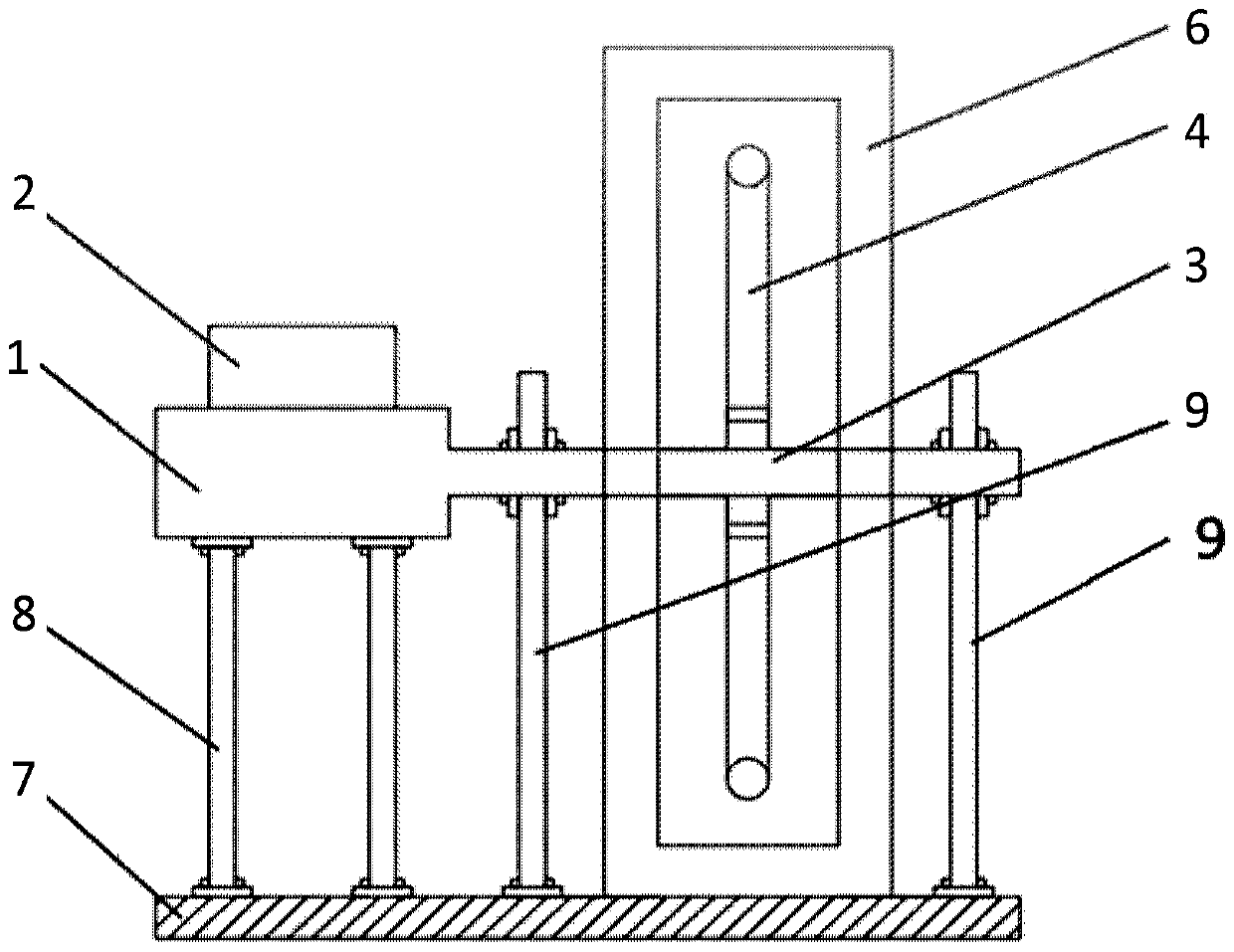

[0029] An embodiment of the present disclosure provides an experimental device for evaluating the collective friction and wear behavior of particle flow, including: a main engine power system, a transmission system (or a main shaft system), a main pipeline circuit 4, a replaceable friction sample part 5, a vacuum system, Temperature-controlled heating system and platform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com