Frame body and battery module

A battery module and frame technology, which is applied to battery pack components, circuits, electrical components, etc., can solve the problems of increasing grouping processes, inability to complete groups, and high consistency requirements, reducing consistency requirements and facilitating Mass production, the effect of reducing the group process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

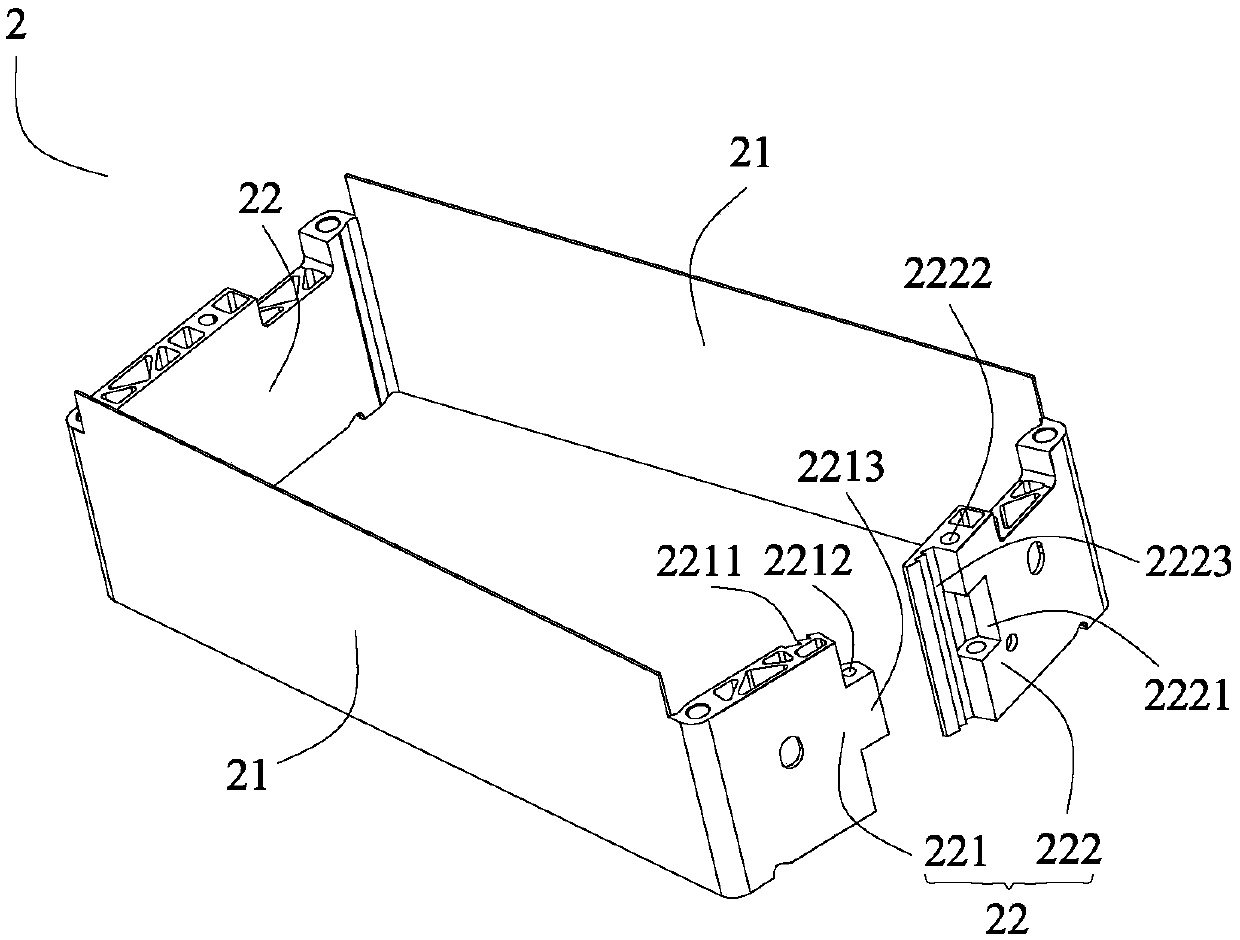

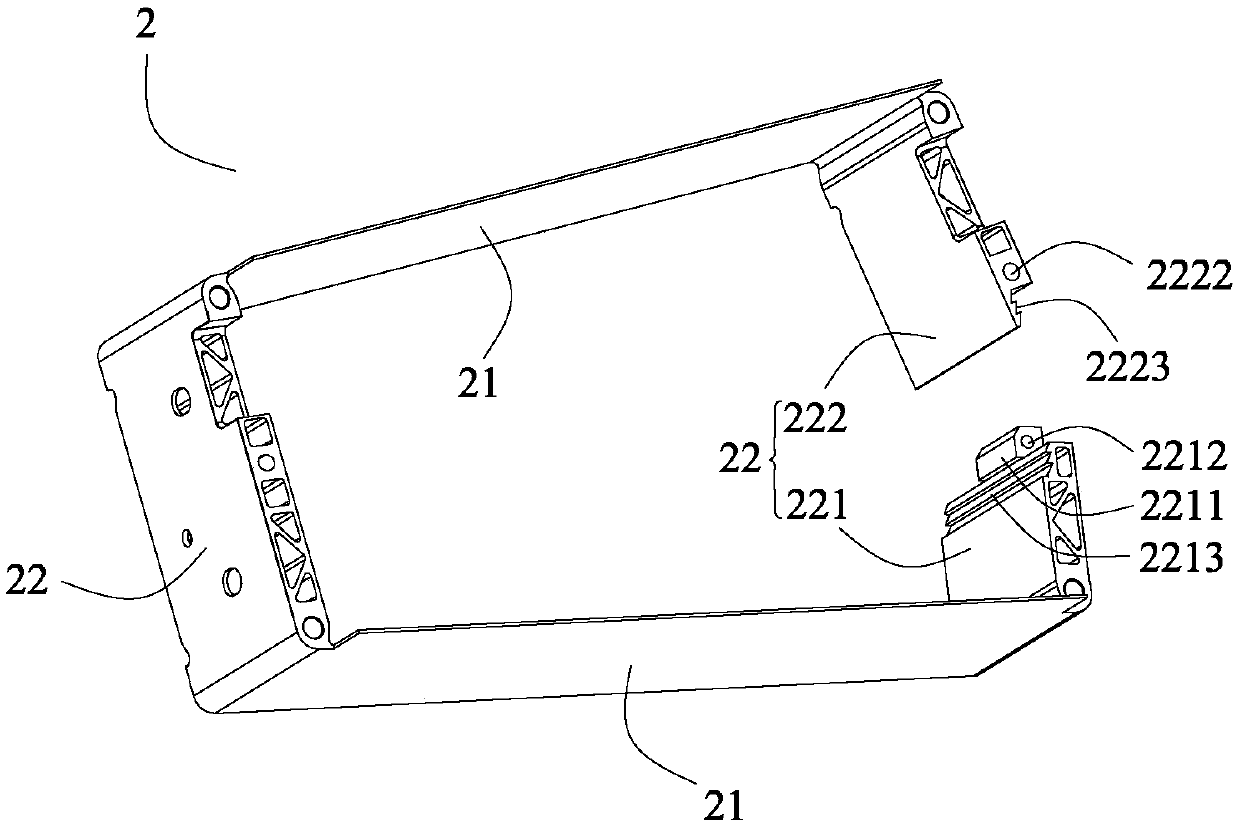

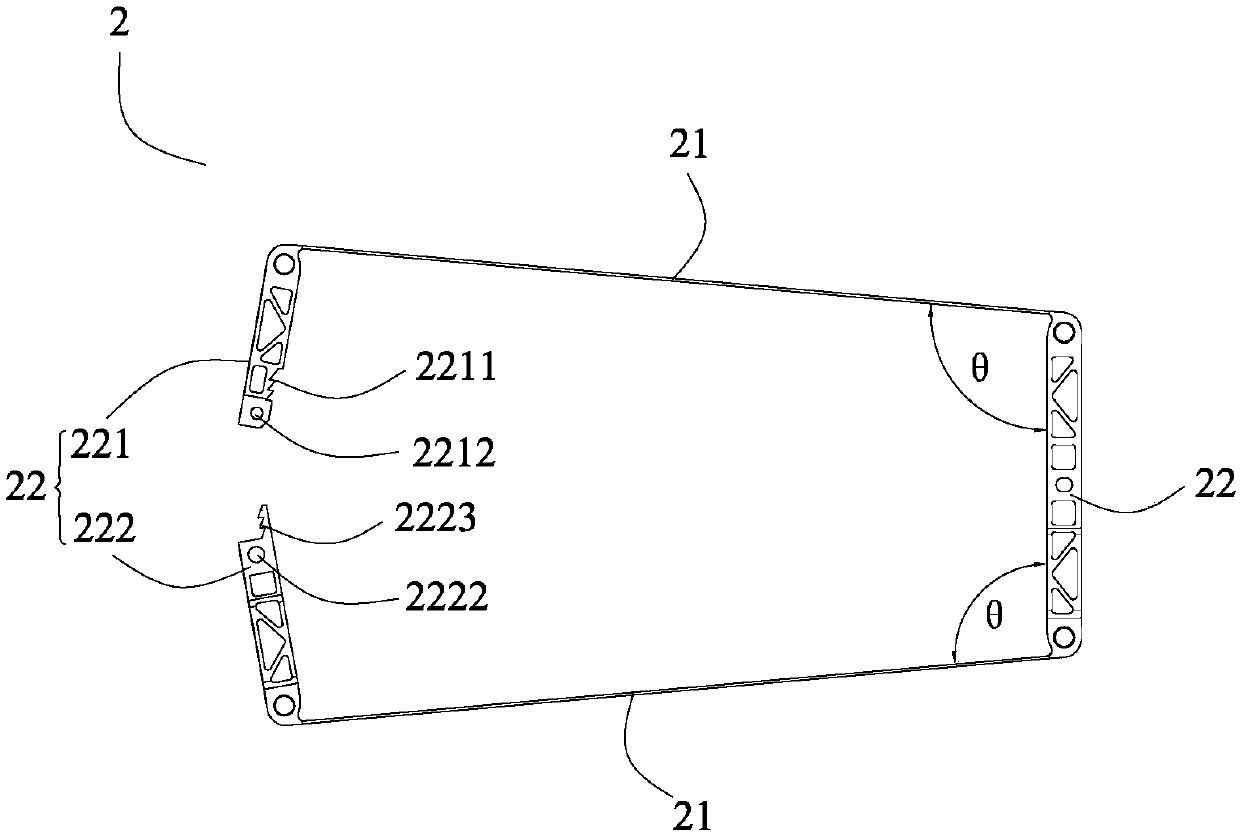

[0026] The frame body and the battery module according to the present invention will be described in detail below with reference to the accompanying drawings.

[0027] First, the housing 2 of the first aspect of the present invention will be described.

[0028] refer to Figure 1 to Figure 6 , the frame body 2 according to the present invention includes: two side plates 21 arranged oppositely; Wherein, at least one end plate 22 is composed of a first connecting plate 221 and a second connecting plate 222, and the first connecting plate 221 and the second connecting plate 222 of the at least one end plate 22 are respectively integrally formed with a corresponding side plate 21 , and the first connecting plate 221 and the second connecting plate 222 of the at least one end plate 22 are opposite and used for fixed connection.

[0029] In the frame body 2 according to the present invention, since at least one end plate 22 of the frame body 2 is composed of a first connecting pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com