Wedge-shaped inward folding synchronous rotating mechanism

A technology of synchronous rotation and rotation mechanism, which is applied in the direction of pivot connection, etc., can solve the problem of high requirements for the inner bending mechanism, and achieve the effect of simple and reasonable structural design, satisfying effectiveness, and realizing effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

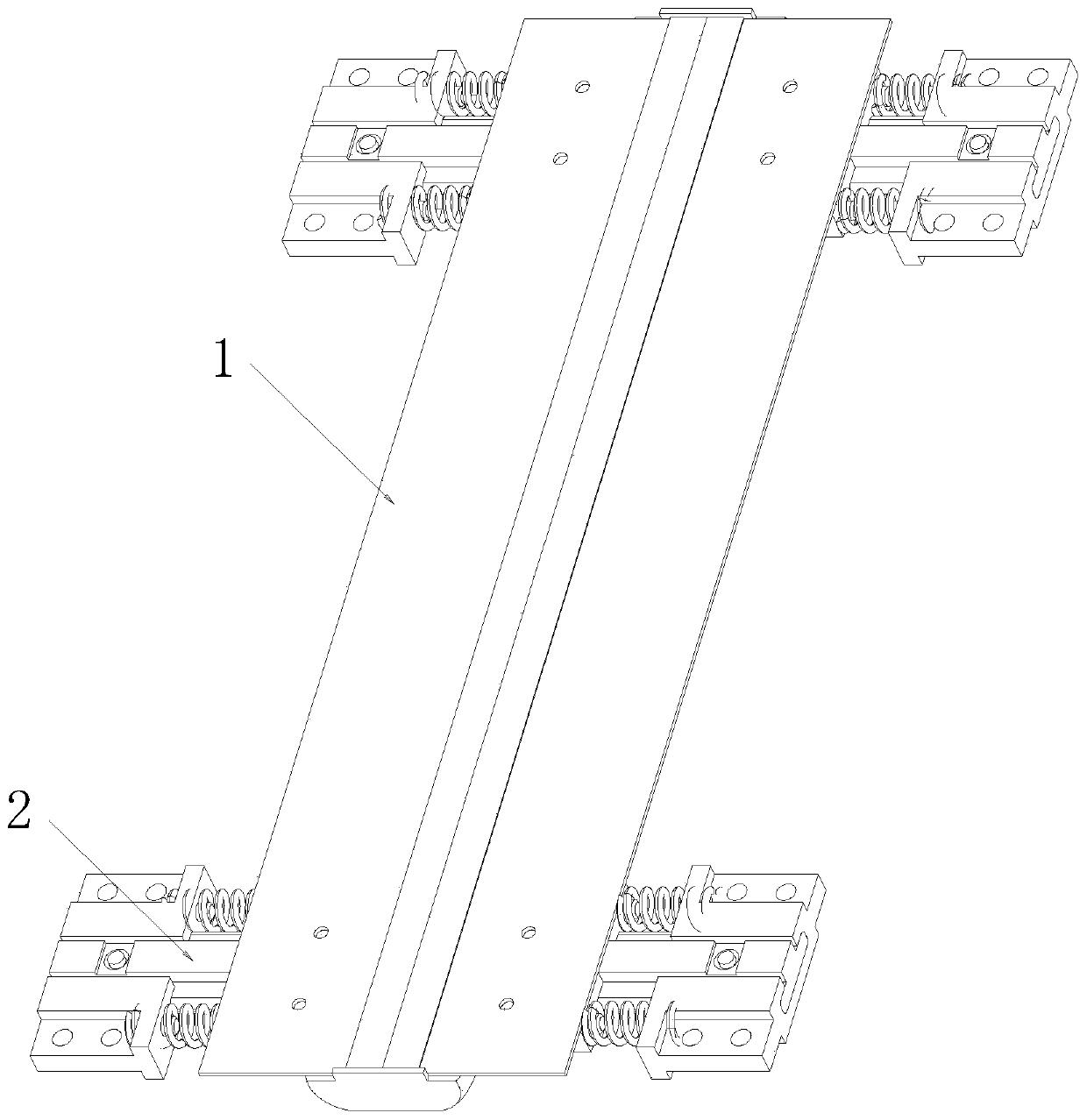

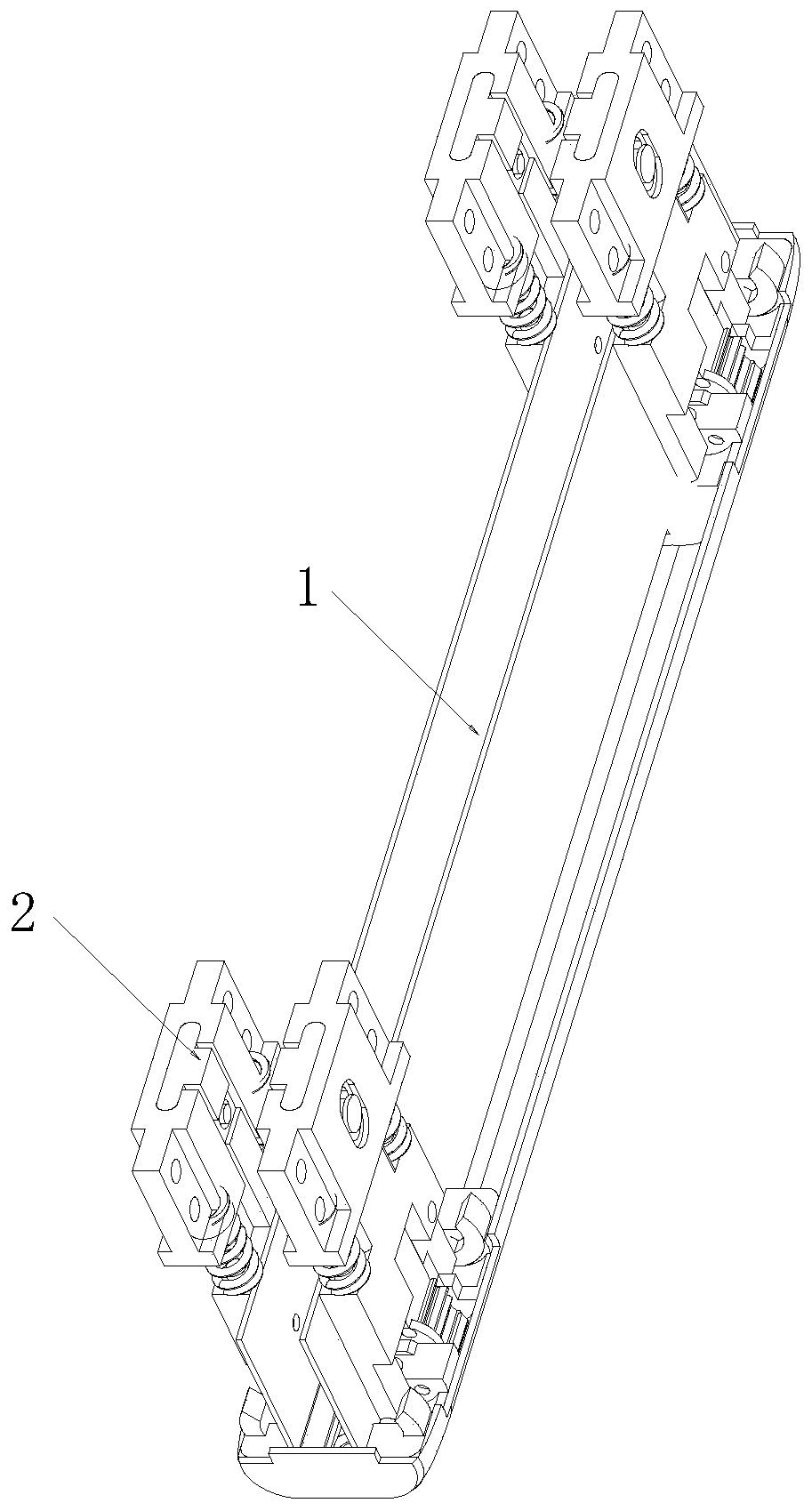

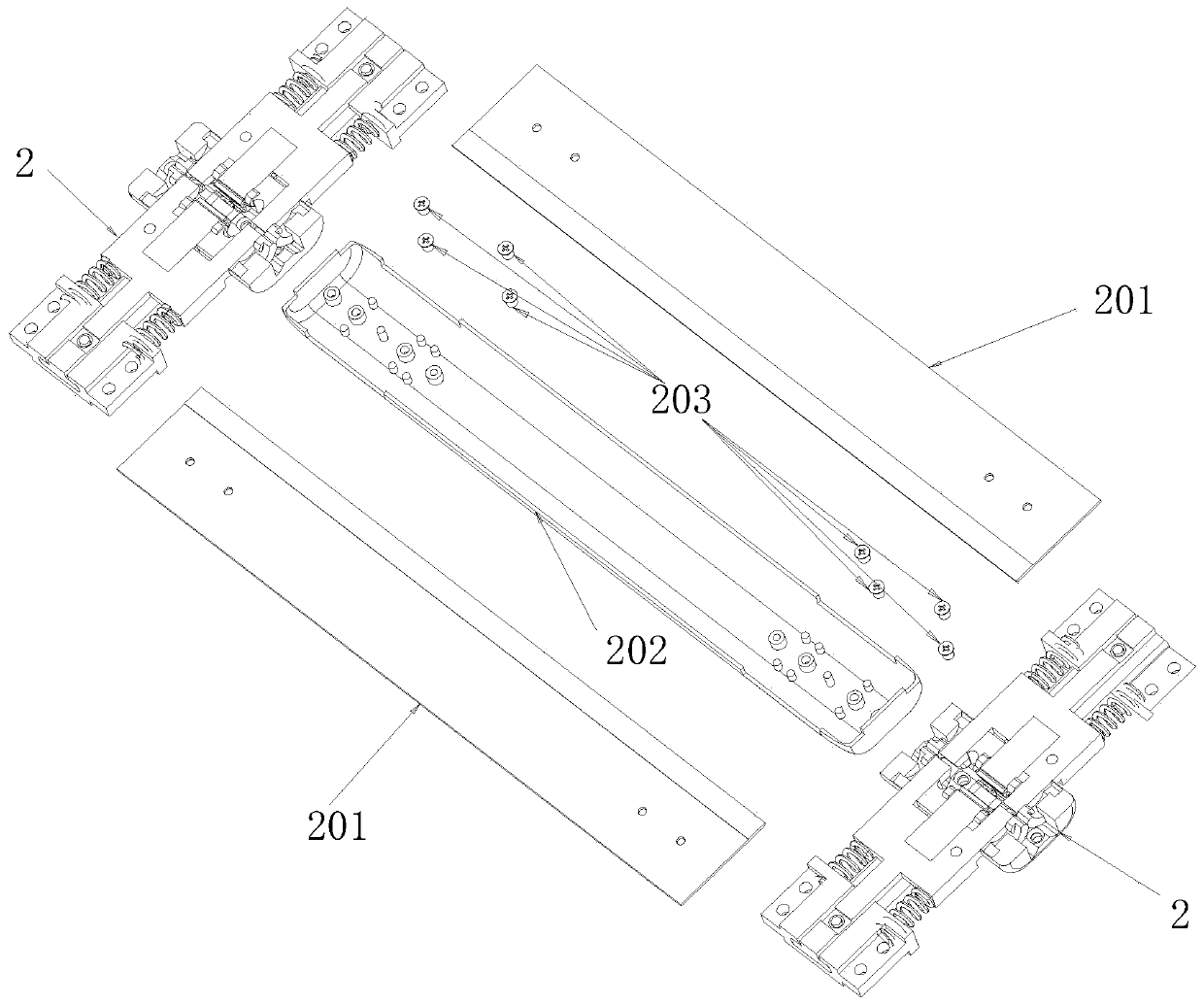

[0027] Such as Figure 1-11 As shown, the wedge-shaped inward-folding synchronous rotating mechanism disclosed in this embodiment, the wedge-shaped inward-folding synchronous rotating mechanism, includes a structural main body, and the structural main body is composed of a package body 1 and a rotating shaft 2 connected at both ends. The rotating shaft 3 and the compensation mechanism 4 arranged on both sides of the rotating shaft 3, the compensation mechanism 4 includes a slide rail seat 5 and a slider 6, and the rotating shaft 3 is composed of a gear set 20 in the middle and a rotating mechanism 7 at both ends , the rotating mechanism 7 includes a first rotating mechanism 8 and a second rotating mechanism 9, and the first rotating mechanism 8 and the second rotating mechanism 9 are respectively provided with a plurality of semicircular arc movable blocks 10, and the first rotating mechanism 8 also includes an elastic block 11, and the second rotating mechanism 9 also include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com