Preparation method of silicon oxide aerogel with grade gradient holes for efficient water evaporation

A silicon oxide airgel and water evaporation technology, applied in the field of nanomaterials, achieves low cost, excellent light and hot water evaporation performance, and meets the needs of water management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

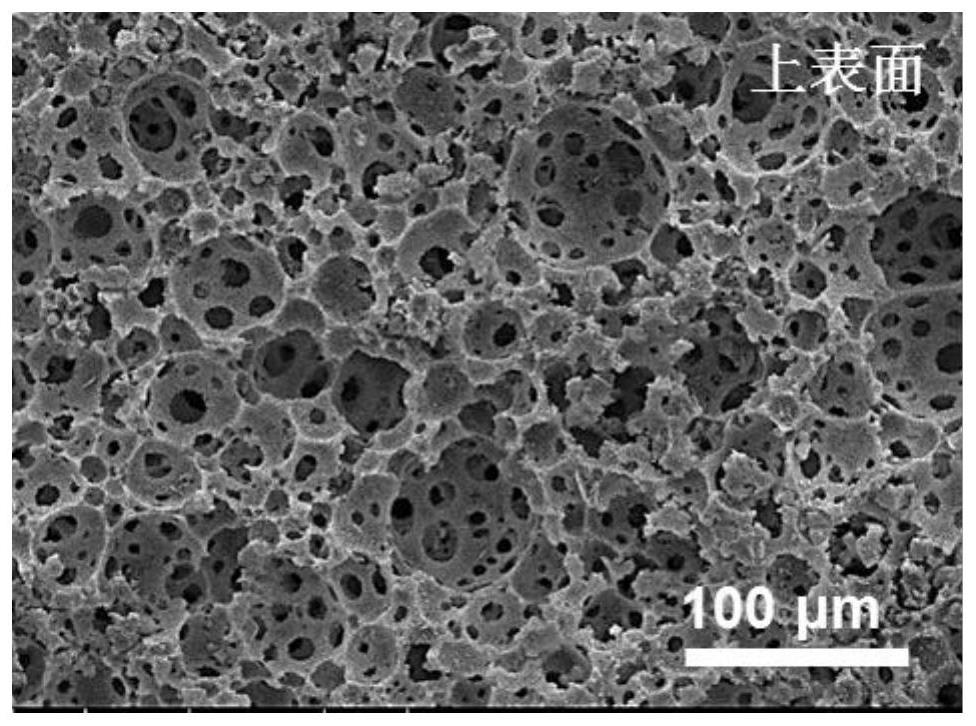

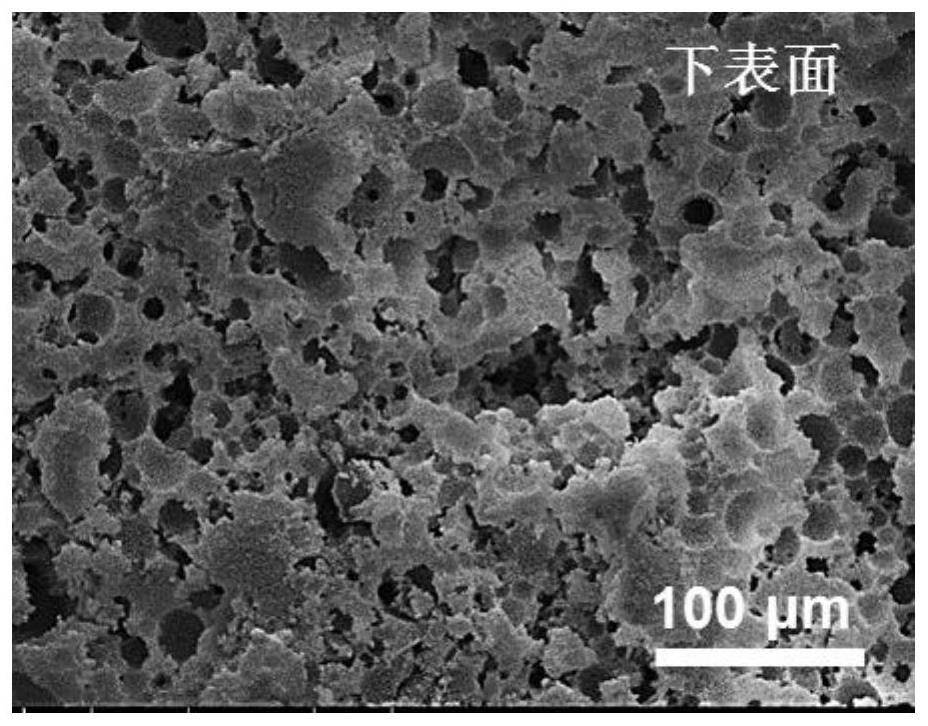

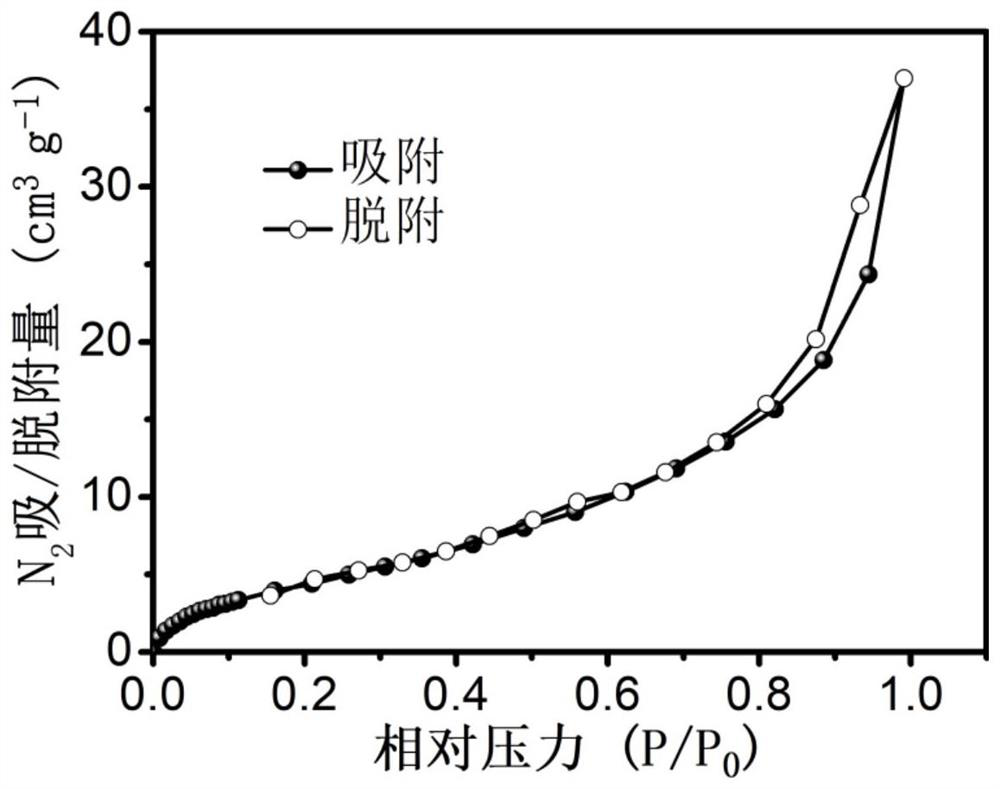

[0029] A method for preparing silica airgel with graded gradient pores for efficient water evaporation, the following steps are used:

[0030] Step 1 Mix 2-5mol / L urea solution with 0.22-0.44mol / L cetyltrimethylammonium bromide solution evenly, and then add glacial acetic acid to make the pH of the solution reach 4.2-4.3 , to obtain a mixed solution A; the mixed solution A is heated and stirred for 2 to 4 hours until completely transparent, wherein the mass ratio of urea to cetyltrimethylammonium bromide is 3:4 to 15:4;

[0031] Step 2 Add tetraethyl orthosilicate to the mixed solution A obtained in step 1, and keep stirring for 20 to 40 minutes until it becomes translucent to obtain a mixed solution B, wherein the mass ratio of urea to orthosilicate is 6: 23.4~15:14;

[0032] Step 3: Pour the mixed solution B obtained in step 2 into a high-temperature-resistant plastic container and seal it tightly, and place the plastic container in an oven at 60-80°C for gelation for 20-30...

Embodiment 1

[0036] A method for preparing silica airgel with graded gradient pores for efficient water evaporation, the following steps are used:

[0037] Step 1 gets the urea of 3mol / L and the cetyltrimethylammonium bromide solution of 0.3mol / L and mixes, and then adds glacial acetic acid wherein and makes the pH value of solution be adjusted to 4.25, obtains mixed solution A; The mixed solution A was heated and stirred for 3h until completely transparent;

[0038] In step 2, add 22.8mL tetraethyl orthosilicate to the mixed solution A obtained in step 1, and continue to stir for 30 minutes until it becomes translucent to obtain mixed solution B;

[0039] Step 3: Pour the mixed solution B obtained in step 2 into a high-temperature-resistant plastic container and seal it tightly, and place the plastic container in an oven at 60°C for gelation for 24 hours;

[0040] Step 4 Pour 20ml of absolute ethanol into the container after step 3, and seal it tightly. After soaking at room temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com