Offline test system for potential energy recovery device

A potential energy recovery and test system technology, applied in the direction of measuring devices, general control systems, control/regulation systems, etc., can solve the problems of cumbersome and complicated processes, high requirements for cooperation, time-consuming and labor-intensive, etc., and achieve high safety, compact structure, The effect of low site demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0067] An off-line potential energy recovery device test system mainly consists of two parts: a mechanical system and an electrical system. There is a program inside, which can automatically complete various tests.

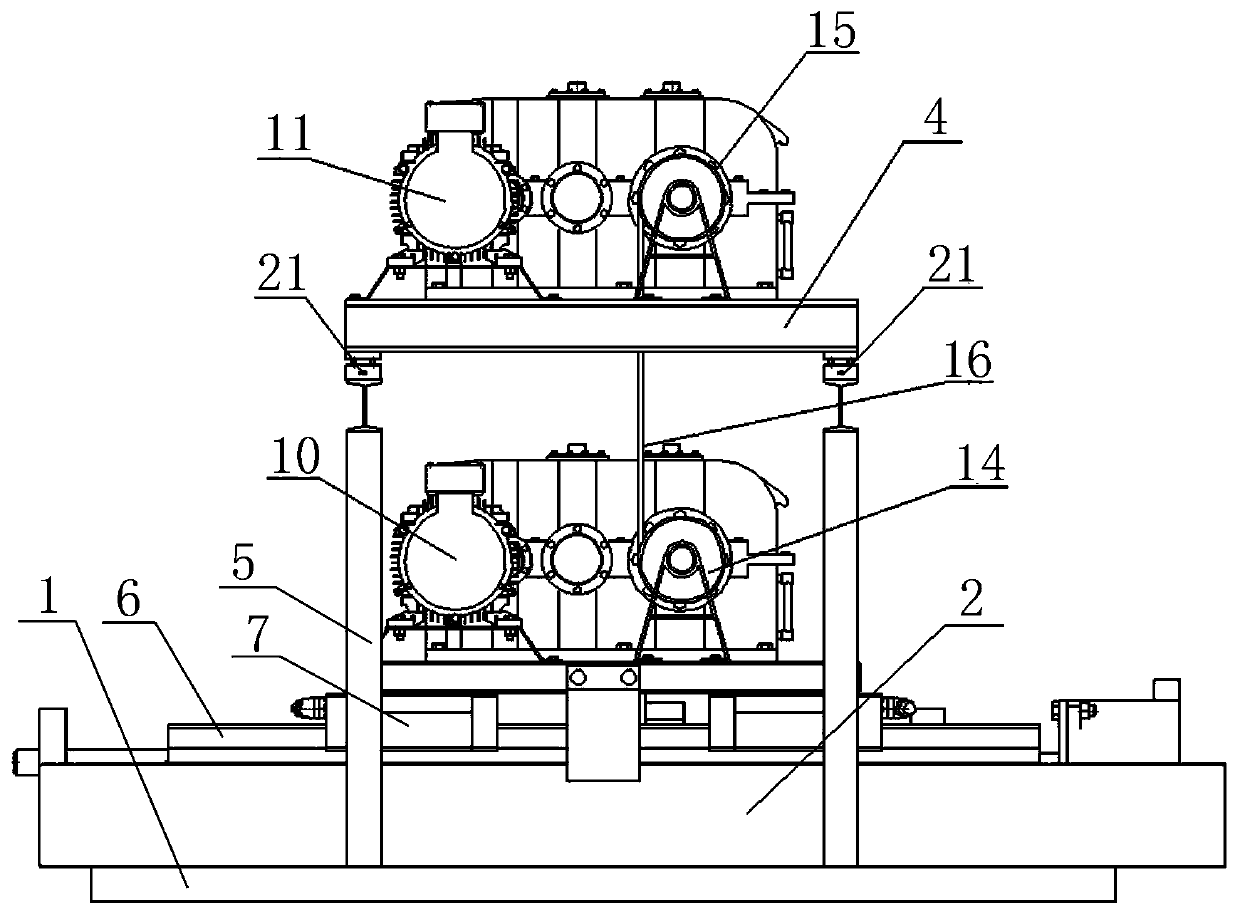

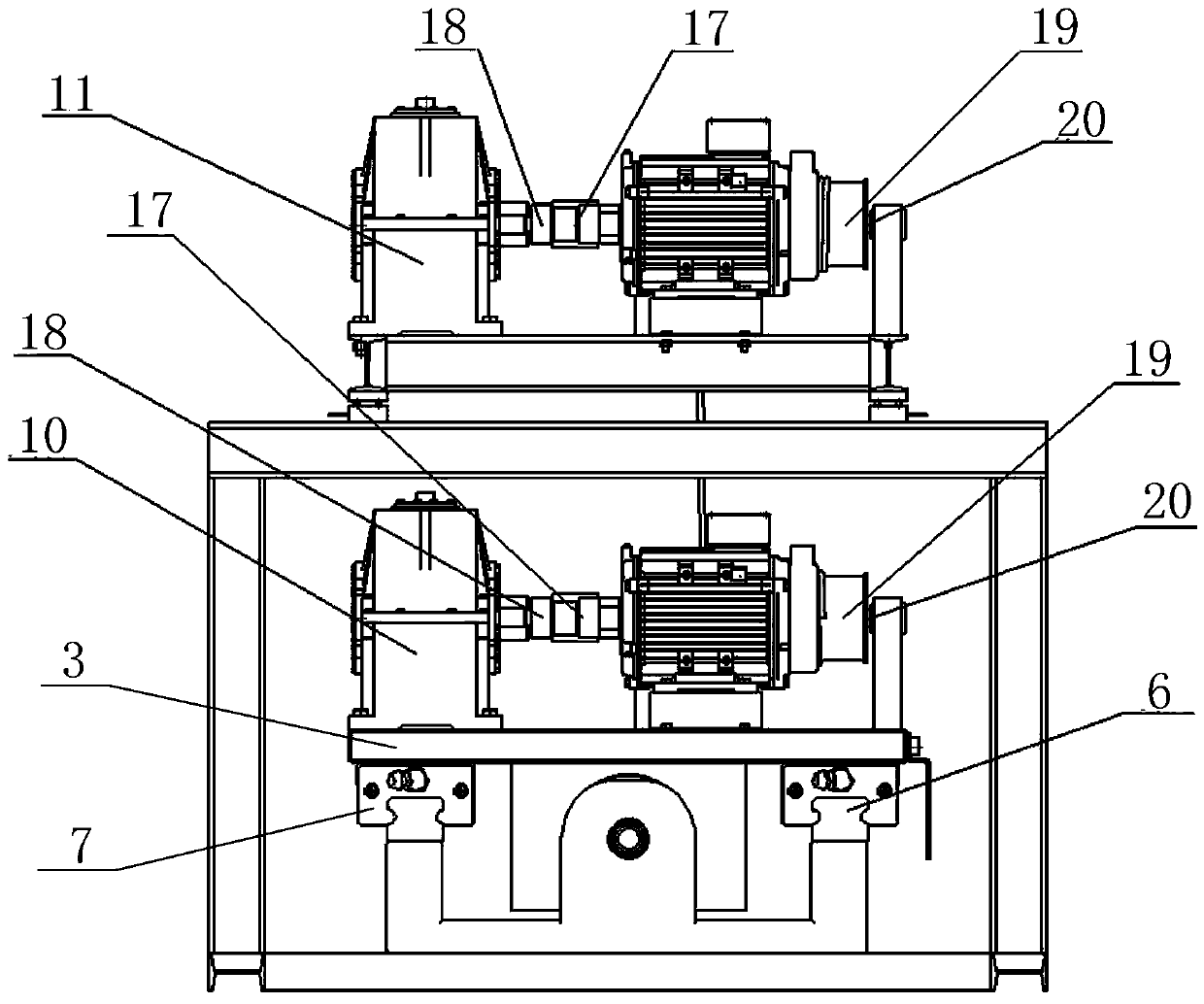

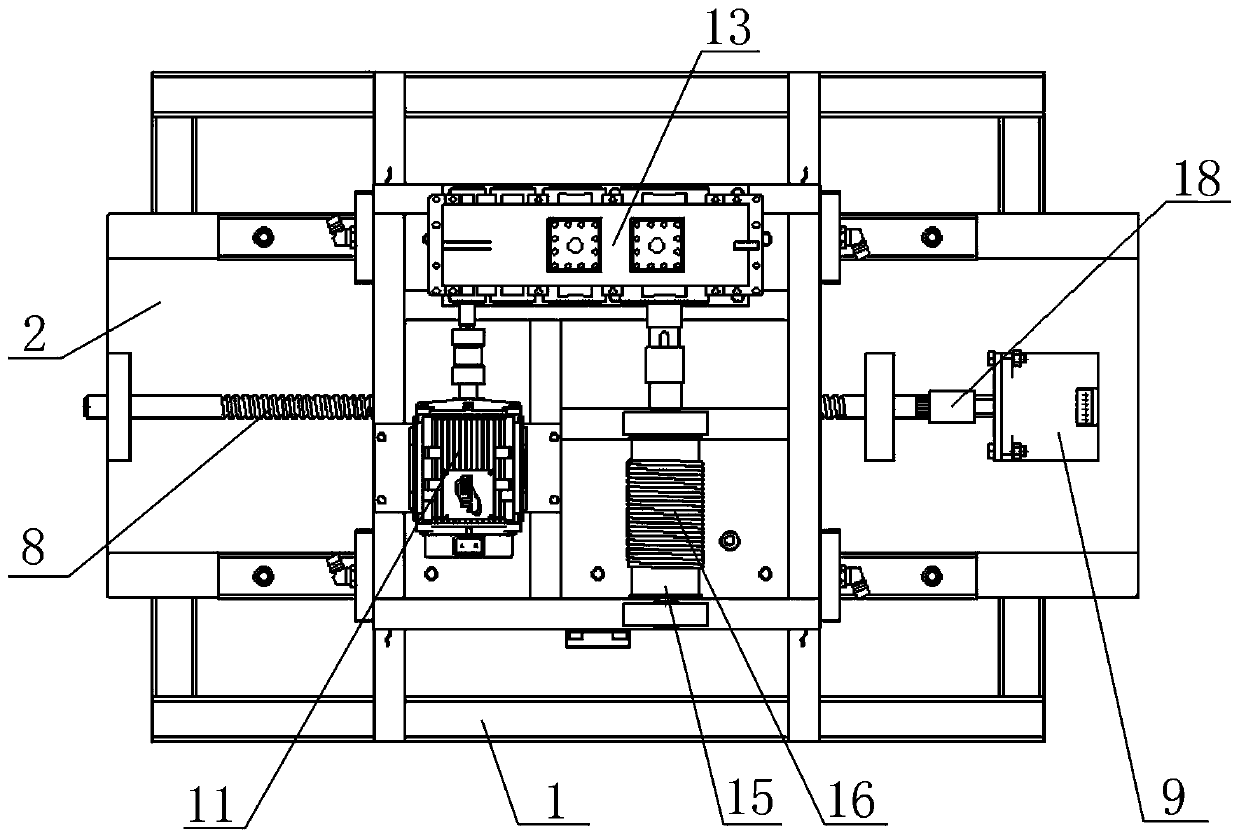

[0068] 1. The mechanical system is mainly composed of three parts: platform support, gravity simulation mechanism and lifting simulation mechanism.

[0069] Such as figure 1 , 2 As shown in . The receiving platform 3 is supported by a lead screw 8 in the middle of the track seat 2, and the end of the lead screw 8 is connected to the output end of the servo motor 9 through a coupling. Torque motor 10, gear box I12 and reel I14 are installed on platform 3, torque sensor 17 is installed at the output end of torque motor 10, and is connected with the input end of gear box I12 through coupling 18, and the output end of gear box I12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com