Cylindrical rotary rheometer device capable of being installed on production line and application method thereof

A rotational rheometer and rheometer technology, applied in the direction of measuring devices, instruments, flow characteristics, etc., can solve time-consuming and labor-intensive problems, and achieve no manual labor, simple and easy technical means, cost reduction and manual measurement effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

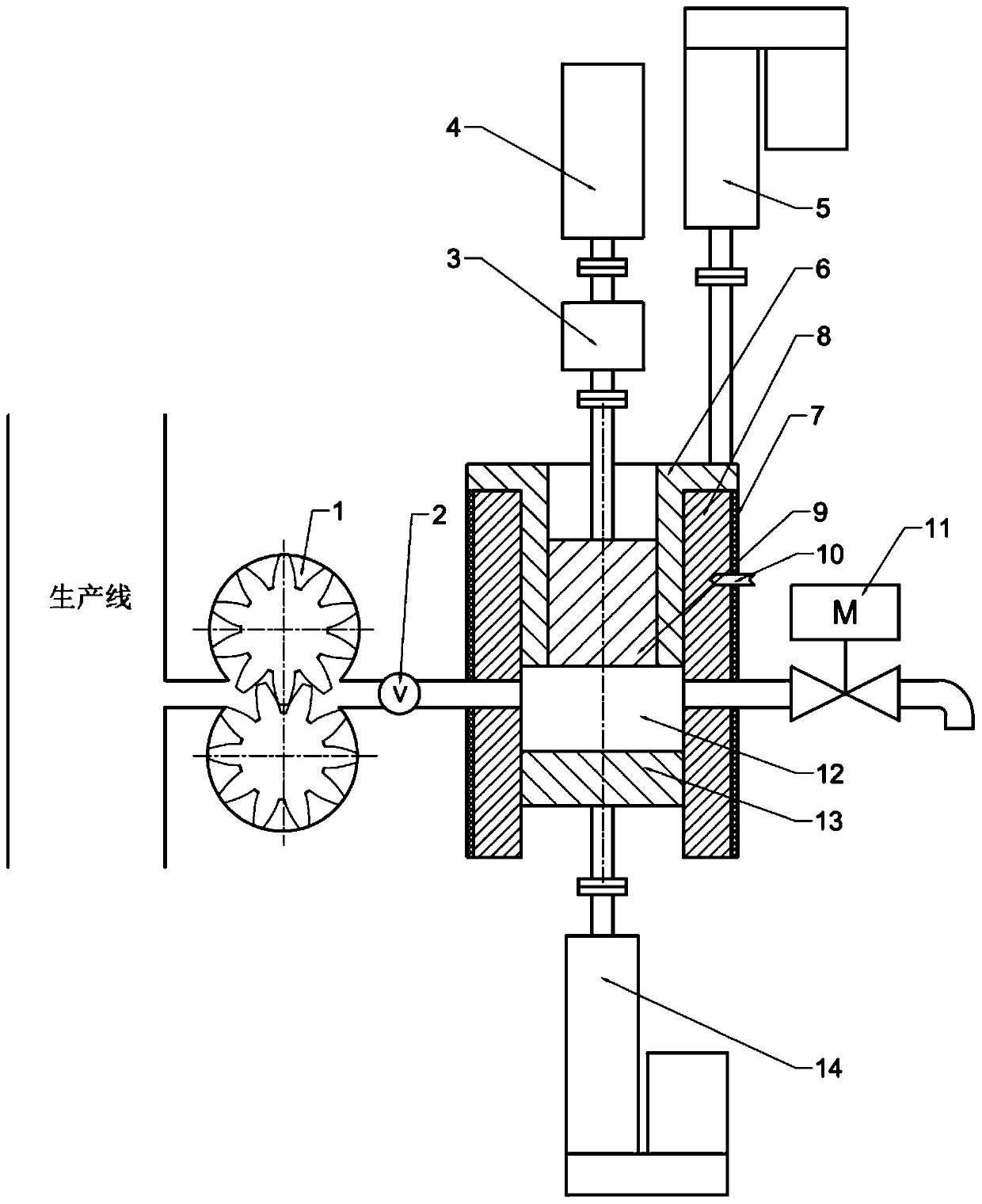

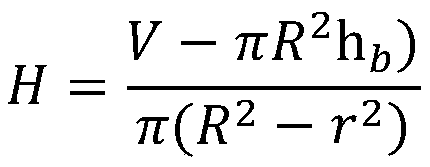

[0032] Such as figure 1 shown. This embodiment discloses a cylindrical rotational rheometer device that can be installed on a production line, including a rheometer base body, a material conveying device, a self-cleaning device, and a volume adjustment device, which realize online measurement on the production line and quickly obtain The rheological characteristics of the material are provided with a material conveying device, a self-cleaning device and a volume adjustment device; the material conveying device is used to control the material in and out, the self-cleaning device is used to clean the inner and outer cylinder walls, and the volume adjustment device is used to Precisely control the volume of experimental materials.

[0033] The self-cleaning device includes a scraping cylinder 6 and an electric push rod 5, and the electric push rod 5 is installed on the scraping cylinder 6; the rheometer base includes an outer cylinder 8, an inner cylinder 9, a temperature contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com