Cutting process

A cutting process and cutting surface technology, which is used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of difficult to clean EMC or SMC substrate cups, strong EMC or SMC substrates, and low production efficiency. The effect of reducing production cost, shortening time-consuming and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

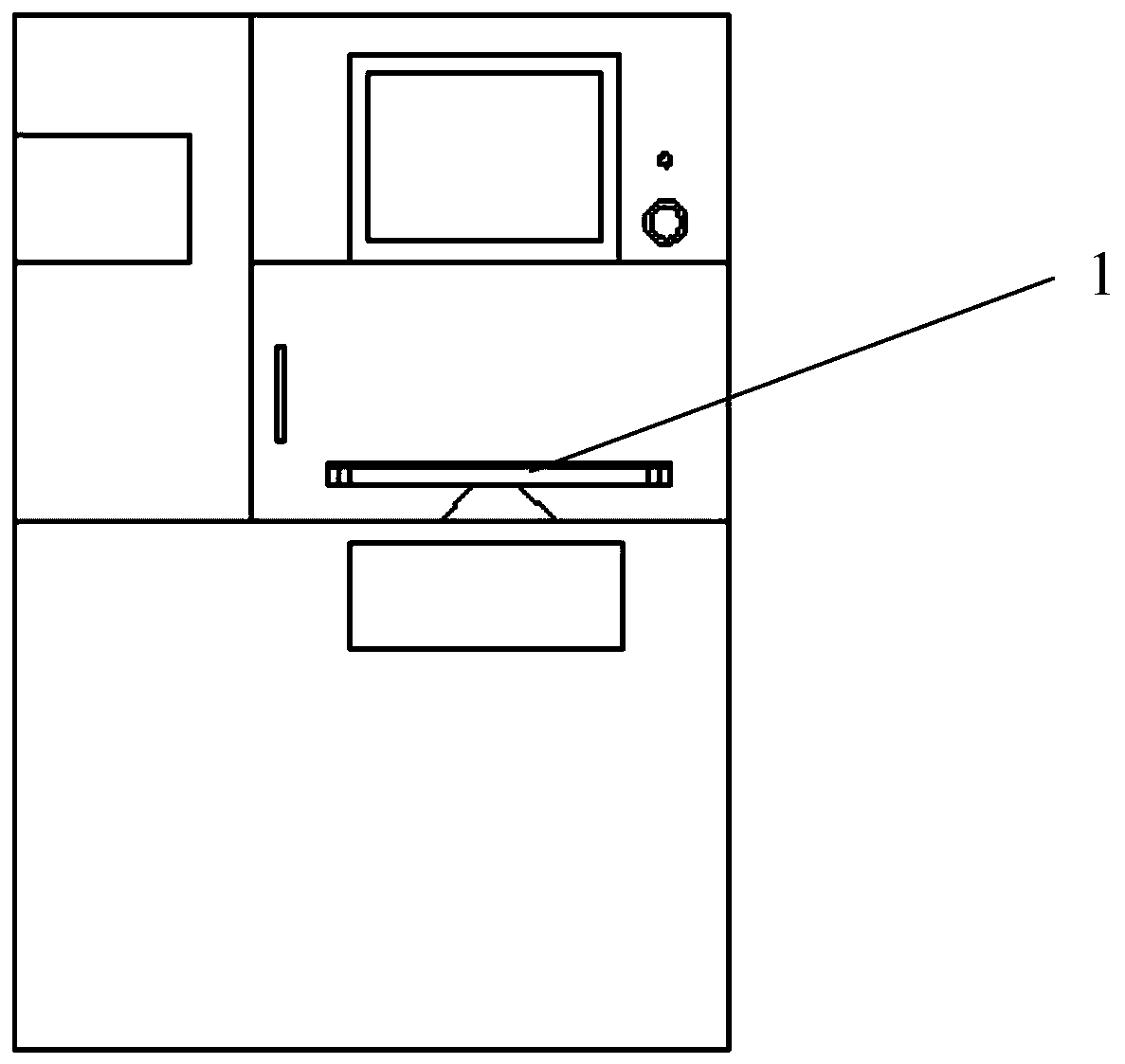

[0028] A cutting process, refer to Figures 1 to 5 , including steps:

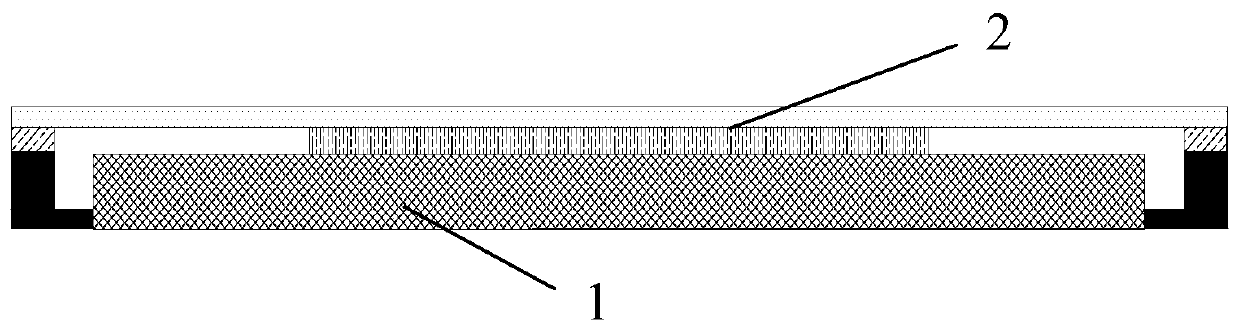

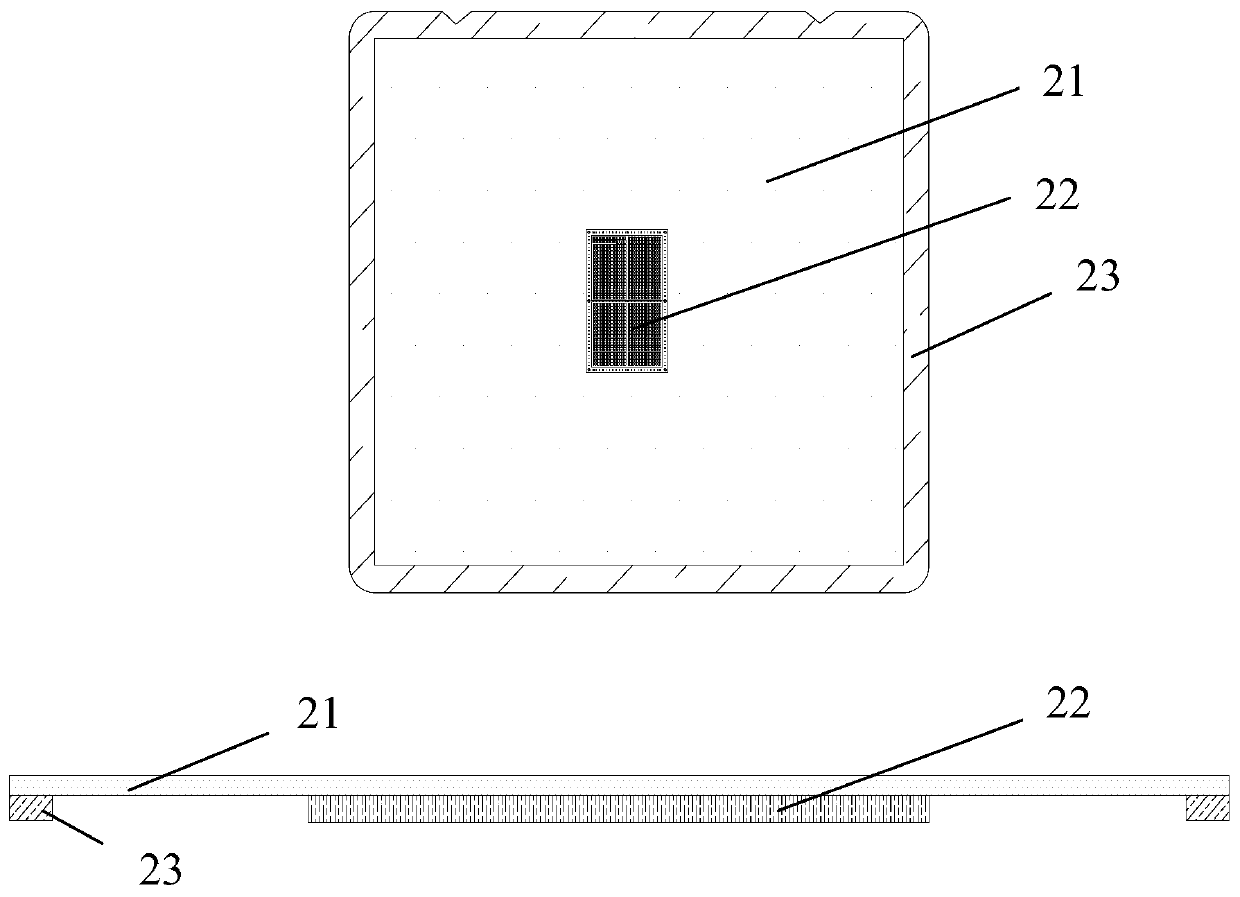

[0029] (1) Paste at least one substrate 22 on the front middle part of the low-viscosity optical film 21; the substrate 22 includes a cutting surface, and the cutting surface of the substrate 22 faces the low-viscosity optical film 21; The surrounding edges of the optical film 21 that are not in contact with the substrate 22 are attached to the front of the low-viscosity optical film 21 to form the substrate assembly 2;

[0030] (2) Put the substrate assembly 2 into the vacuum workbench of the automatic cutting machine, the side of the low-viscosity optical film 21 pasted with the substrate 22 is facing the vacuum workbench, that is, the low-viscosity optical film 21 and the vacuum workbench are provided with Described substrate 22, there is cutting track 3 on the cutting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com