Diaphragm for diaphragm valve and manufacturing method thereof

A diaphragm valve and diaphragm technology, applied in the field of diaphragms for diaphragm valves and their manufacturing, can solve the problems of huge manufacturing difficulty and limited work performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

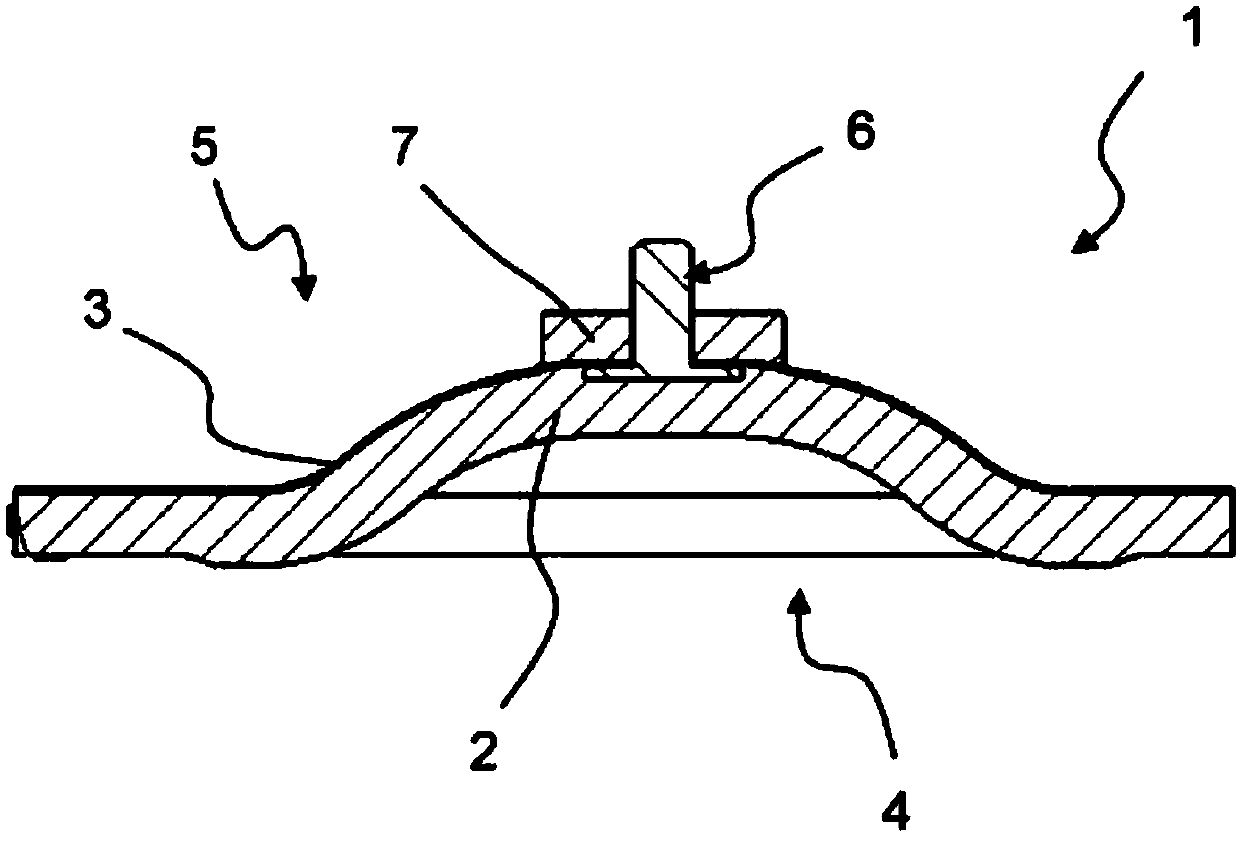

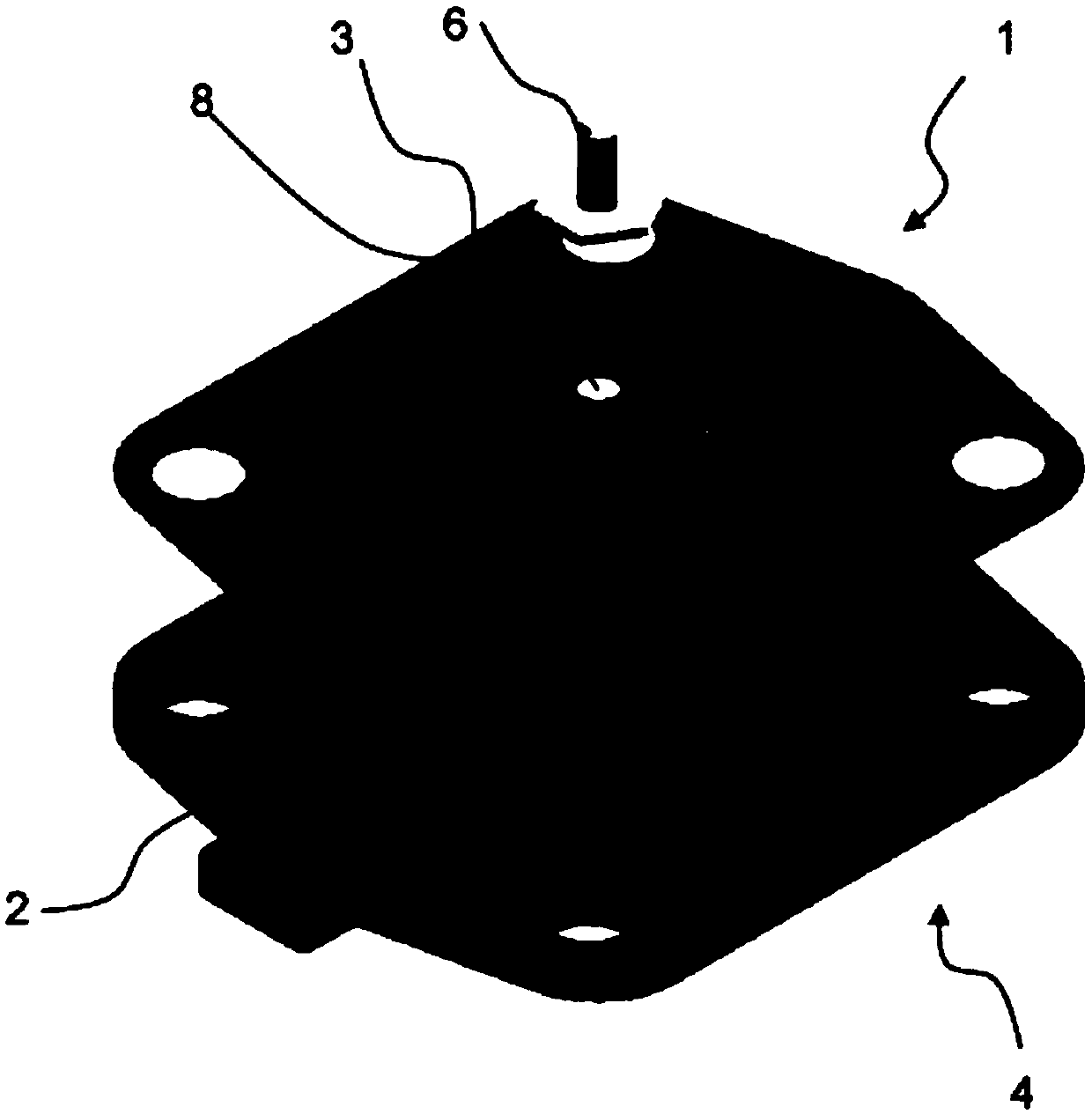

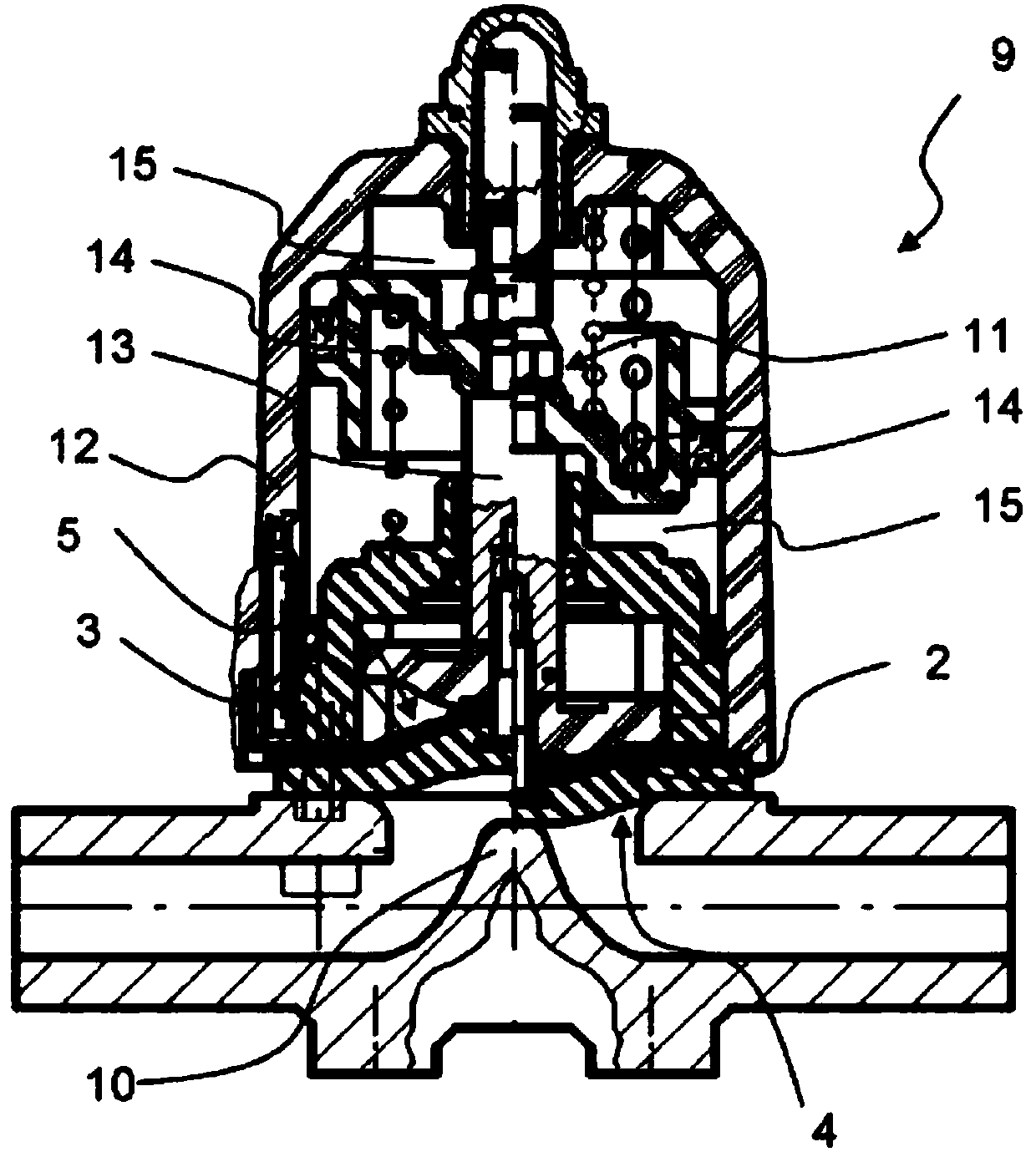

[0039] figure 1 Shown is a membrane 1 comprising a bell-shaped body 2 and a reinforcement area 3 applied to the body 2 . The bottom side of the membrane 1 is the side 4 facing the medium; the top side of the membrane 1 is the side 5 facing away from the medium. On the side 5 of the membrane 1 facing away from the medium, a force transmission component 6 is embedded in the body 2 in such a way that the reinforcement region 3 is also connected to the force transmission component 6 . The force transmission member 6 is used to direct the diaphragm 1 towards the image 3 The valve seat 10 shown below the force transmission member 6 moves and moves away. In order to transmit the force as uniformly as possible to the diaphragm 1 , the force transmission component is partially surrounded by elastomer projections 7 . In this region, the membrane 1 is three-layered, since the reinforcement region 3 extends over the entire surface of the body 1 of the membrane 1 on the side 5 facing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com