A kind of protein glue and preparation method thereof

A technology of adhesives and proteins, applied in the field of protein adhesives and its preparation, can solve problems such as large performance differences, environmental impact, impact, etc., and achieve the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

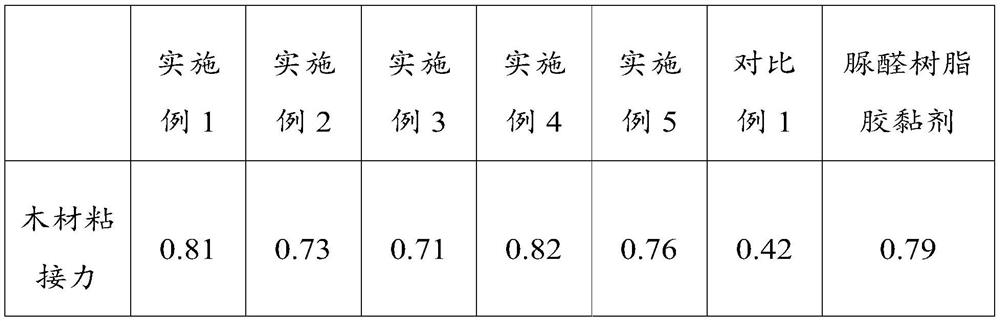

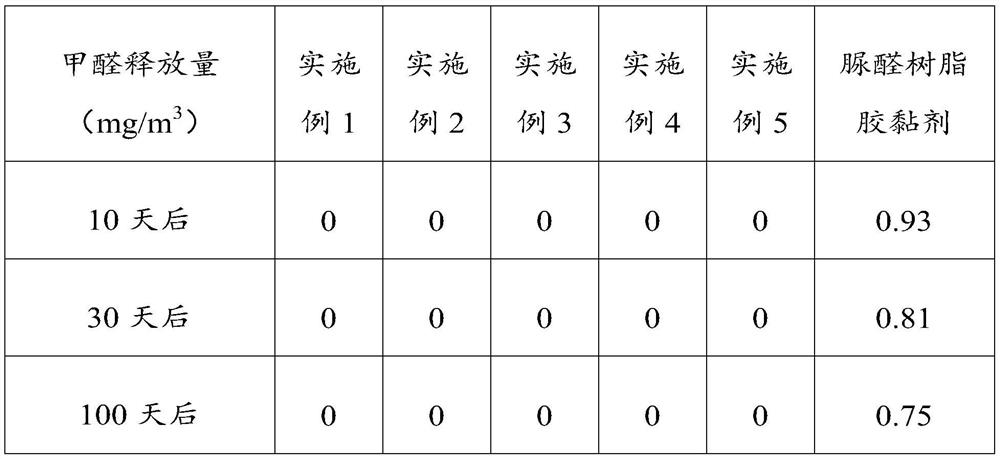

Examples

Embodiment 1

[0063] An embodiment of the present invention provides a protein adhesive.

[0064] In parts by weight, the protein adhesive comprises the following raw materials: 120 parts of water, 60 parts of collagen extracted from tanning waste, 9 parts of urea, 8 parts of alkylsulfonyl chloride and 12 parts of epichlorohydrin.

Embodiment 2

[0066] An embodiment of the present invention provides a protein adhesive.

[0067] In parts by weight, the protein adhesive includes the following raw materials: 120 parts of water, 60 parts of collagen extracted from tanning waste, 9 parts of dicyandiamide, 8 parts of 15 alkyl chlorides, 12 parts of cyclic Oxybromopropane, 2 parts Zinc Oxide, 2 parts Sodium Borate, and 15 parts Light Calcium.

Embodiment 3

[0069] An embodiment of the present invention provides a protein adhesive.

[0070] In parts by weight, the protein adhesive includes the following raw materials: 150 parts of water, 80 parts of collagen extracted from tanning waste, 12 parts of melamine, 10 parts of 16 alkyl alcohol, 15 parts of epichlorohydrin, 3 parts zinc sulfate, 3 parts boric acid and 20 parts kaolin.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap