A three-telescopic column with two-stage support function

A column and function technology, applied in the directions of pillars/supports, mining equipment, earthwork drilling, etc., can solve the problems of high labor intensity of single pillars, slow support and retraction speed, and easy early fall of roadway roofs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

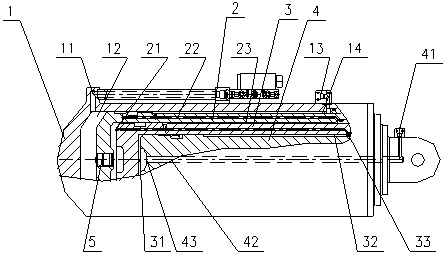

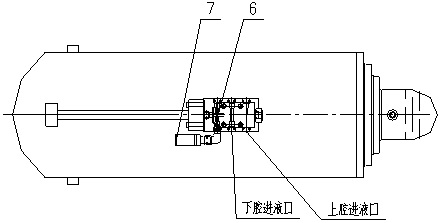

[0021] Two-level support function and three telescopic columns such as figure 1 As shown, it mainly includes four parts: an outer cylinder 1, a first-level middle cylinder 2, a second-level middle cylinder 3 and a live column 4; the outer cylinder 1 is provided with a lower chamber liquid hole 11 and an upper chamber liquid hole 13, and the lower chamber liquid hole 11 Connect the hydraulically controlled one-way valve 6 and the safety valve 7, install the safety valve 7 to communicate with the lower chamber 12 of the outer cylinder, and the upper chamber liquid hole 13 to communicate with the liquid inlet of the upper chamber of the hydraulically controlled one-way valve; the first-stage middle cylinder 2 Located in the outer cylinder 1, the bottom valve 5 is installed at the bottom of the first-stage middle cylinder. When the lower chamber 21 of the first-stage middle cylinder shrinks to contact with the outer cylinder 1, the liquid in the lower chamber 21 of the first-stage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com