Flexible light emitting strip

A light-emitting strip and flexible technology, applied in the field of flexible light-emitting strips, can solve the problems of cumbersome procedures and joints of strip-shaped decorative lights, and achieve the effect of the overall color unchanged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

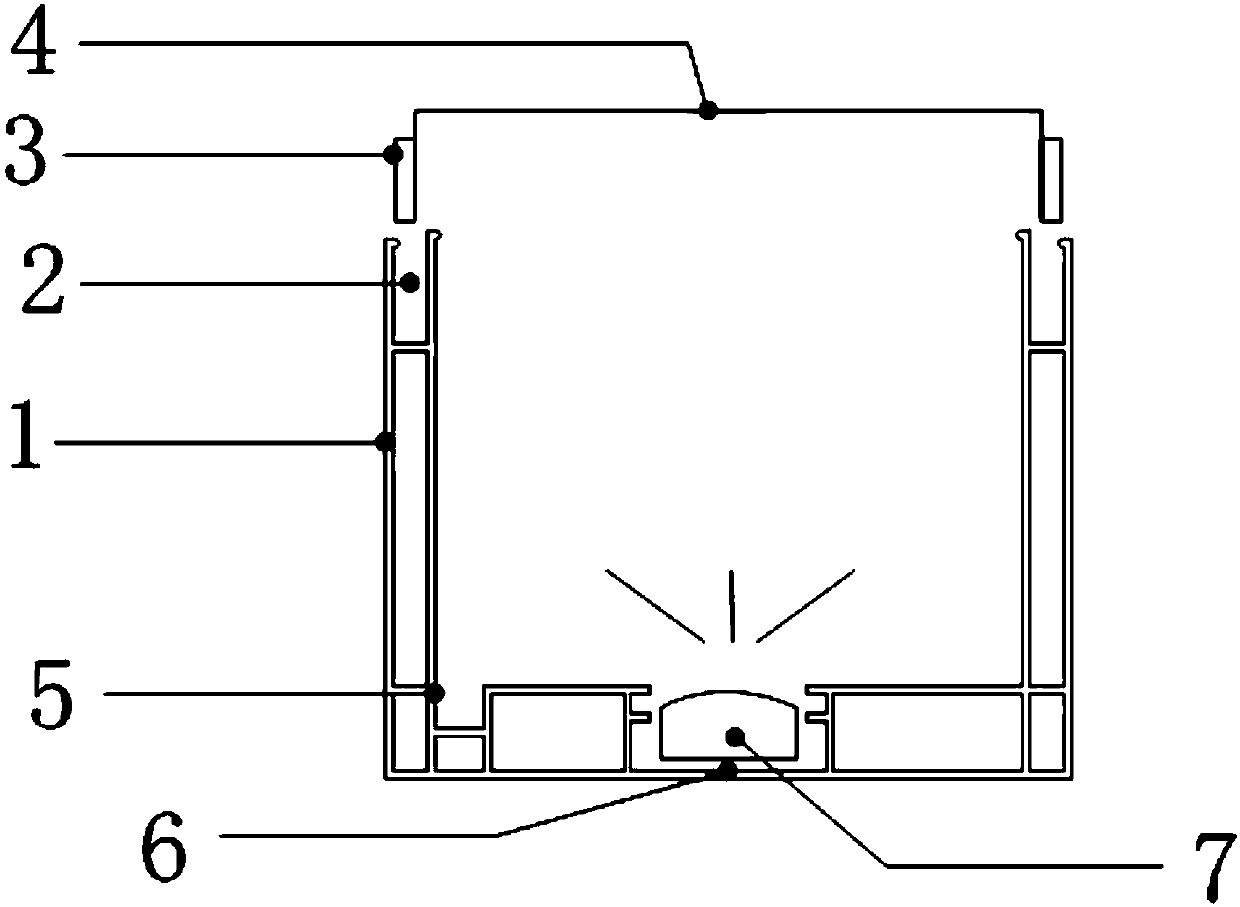

[0027] Embodiment 1, the present embodiment is attached figure 1 As shown, it is also the embodiment scheme mentioned in the claims of the present invention, the sticky rod fixing groove 2 and the sticky rod 3 are in-line, which is convenient and quick.

Embodiment 2

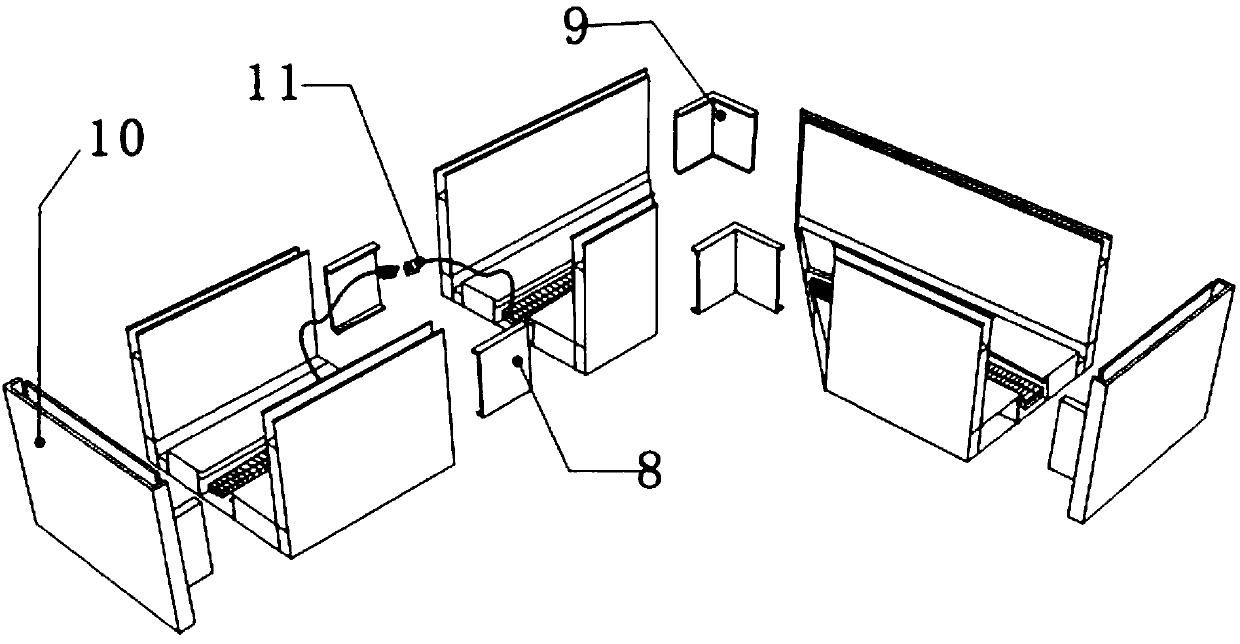

[0028] Embodiment 2, the present embodiment is attached Figure 4 As shown, the sticky rod 3 is changed into a hook shape, so that it is not easy to fall off after being inserted into the sticky rod fixing groove 2, and is stable and reliable.

Embodiment 3

[0029] Embodiment 3, this embodiment is attached Figure 5 As shown, the sticking rod 3 is directly arranged inside the sticking rod fixing groove 2 , and during installation, the flexible board 4 can be inserted into the gap inside the sticking rod 3 using a tool.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap