Concrete curing device and curing method for winter construction in cold region

A technology for concrete and cold areas, which is applied in the manufacture of tools, ceramic molding machines, etc., can solve the problems of difficult concrete development of compressive strength, high energy consumption of concrete maintenance measures, and hidden safety hazards, and achieve uniform curing effect and uniform curing , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

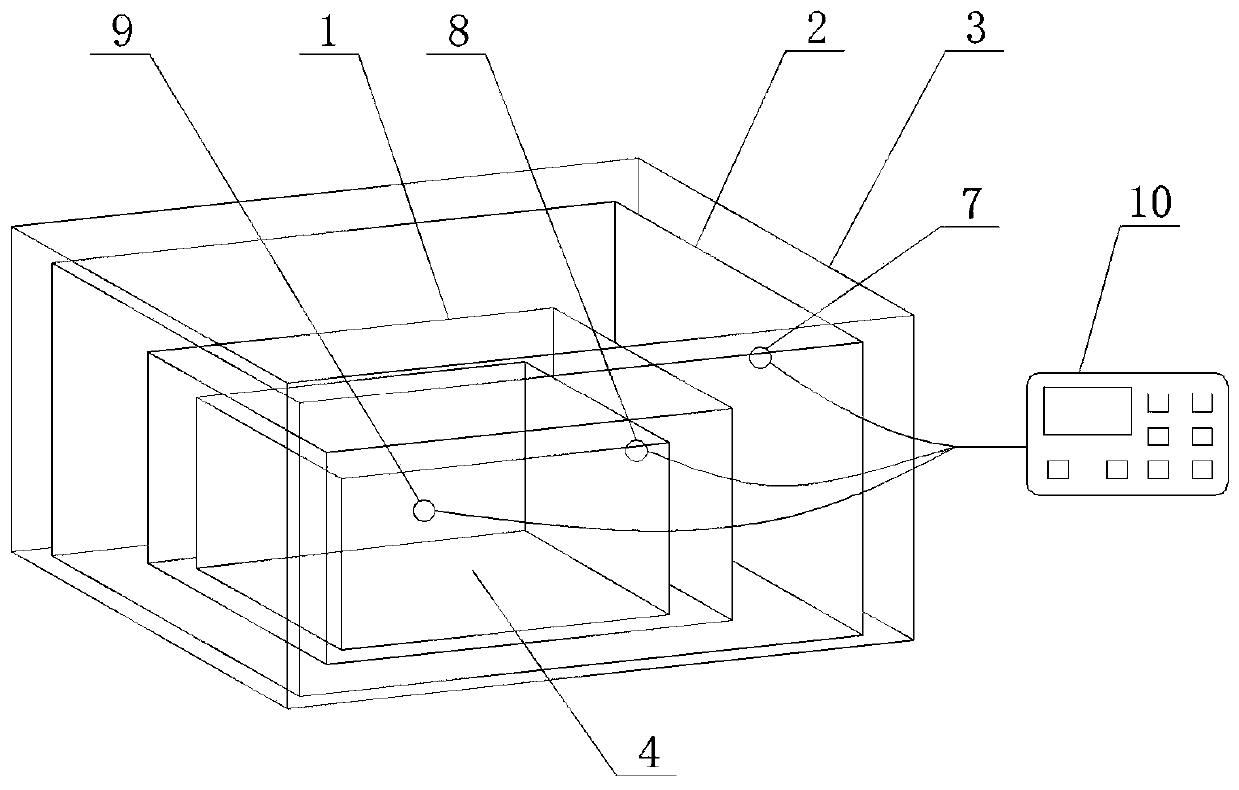

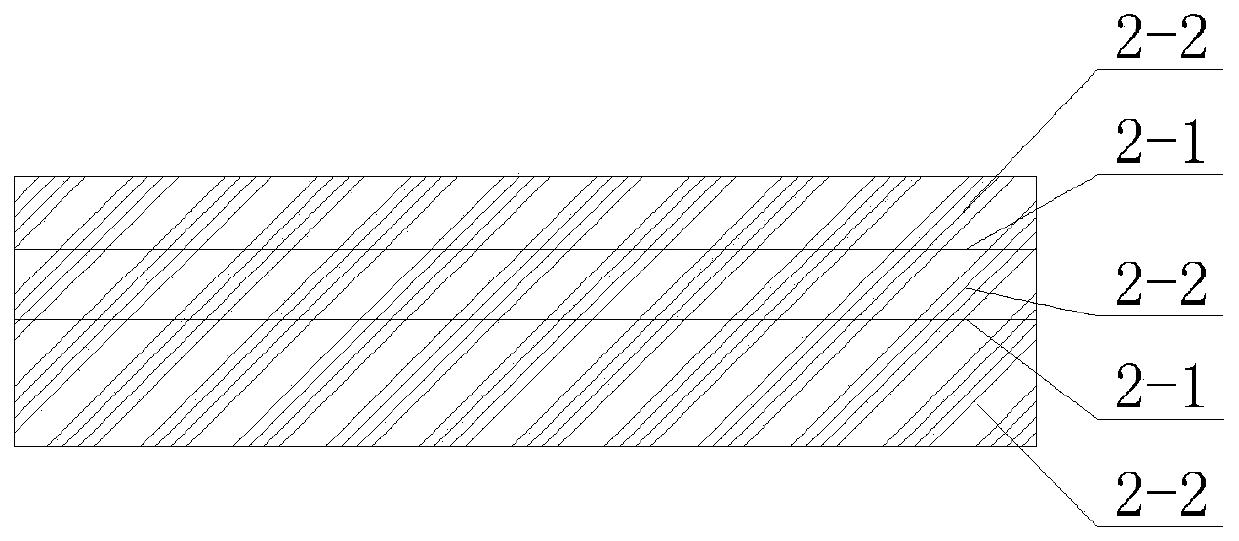

[0048] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 and Figure 12 Describe this embodiment, this embodiment comprises formwork frame, phase-change material layer 2 and insulation layer 3, and described formwork frame comprises top board 1-1, bottom board 1-2 and four side boards 1-3, and four side boards 1 -3 are vertically arranged side by side, four side panels 1-3 are enclosed in turn to form a rectangular frame body, the rectangular frame body is filled with concrete 4, the top plate 1-1 and the bottom plate 1-2 are horizontally arranged on the top and bottom of the rectangular frame body , the outer wall of the template frame is provided with a phase change material layer 2; the phase change material layer 2 outside the top plate 1-1 plays a role in the maintenance of the top surface of the concrete 4, and the phase change material laye...

specific Embodiment approach 2

[0055] Specific embodiment two: this embodiment is a further limitation of specific embodiment one, such as Figure 8 , Figure 9 and Figure 10 As shown, the transverse section of the rectangular frame can be arranged in various forms. The first is that the transverse section of the rectangular frame is smaller than the area of the top plate 1-1, and the second is that the transverse section of the rectangular frame is smaller than that of the bottom plate 1-2. Plate area, the third is that the transverse section of the rectangular frame is smaller than the plate area of the top plate 1-1, and the transverse section of the rectangular frame is smaller than the plate area of the bottom plate 1-2. The above-mentioned various settings are all for the rectangular frame. A space filled with the phase-change material layer 2 is formed between the outer wall and the top plate 1-1 or the bottom plate, which facilitates side maintenance of the concrete 4 .

[0056] The outer w...

specific Embodiment approach 3

[0062] Embodiment 3: This embodiment is the maintenance method implemented by the maintenance device mentioned in Embodiment 1 or 2. Specifically, a suitable phase change material is selected and prepared, and the phase change material is placed between the formwork frame and the insulation layer 3 to form Phase-change material layer 2, pre-embedded temperature sensors in the formwork frame, phase-change material layer 2 realizes heat transfer to concrete 4 through the formwork frame, and phase-change material layer 2 realizes continuous heating and maintenance of concrete 4 by repeated charging and discharging process, when the concrete 4 is molded to a predetermined age, the compressive strength of the concrete 4 is detected. The predetermined age is three days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com