Height-adaptive type indoor transferring platform

An adaptive and load-shifting technology, applied in the direction of lifting devices, etc., can solve the problems of long loading and unloading time, low efficiency of loading and unloading, high production cost, etc., and achieve the effect of simple structure, quick adjustment and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

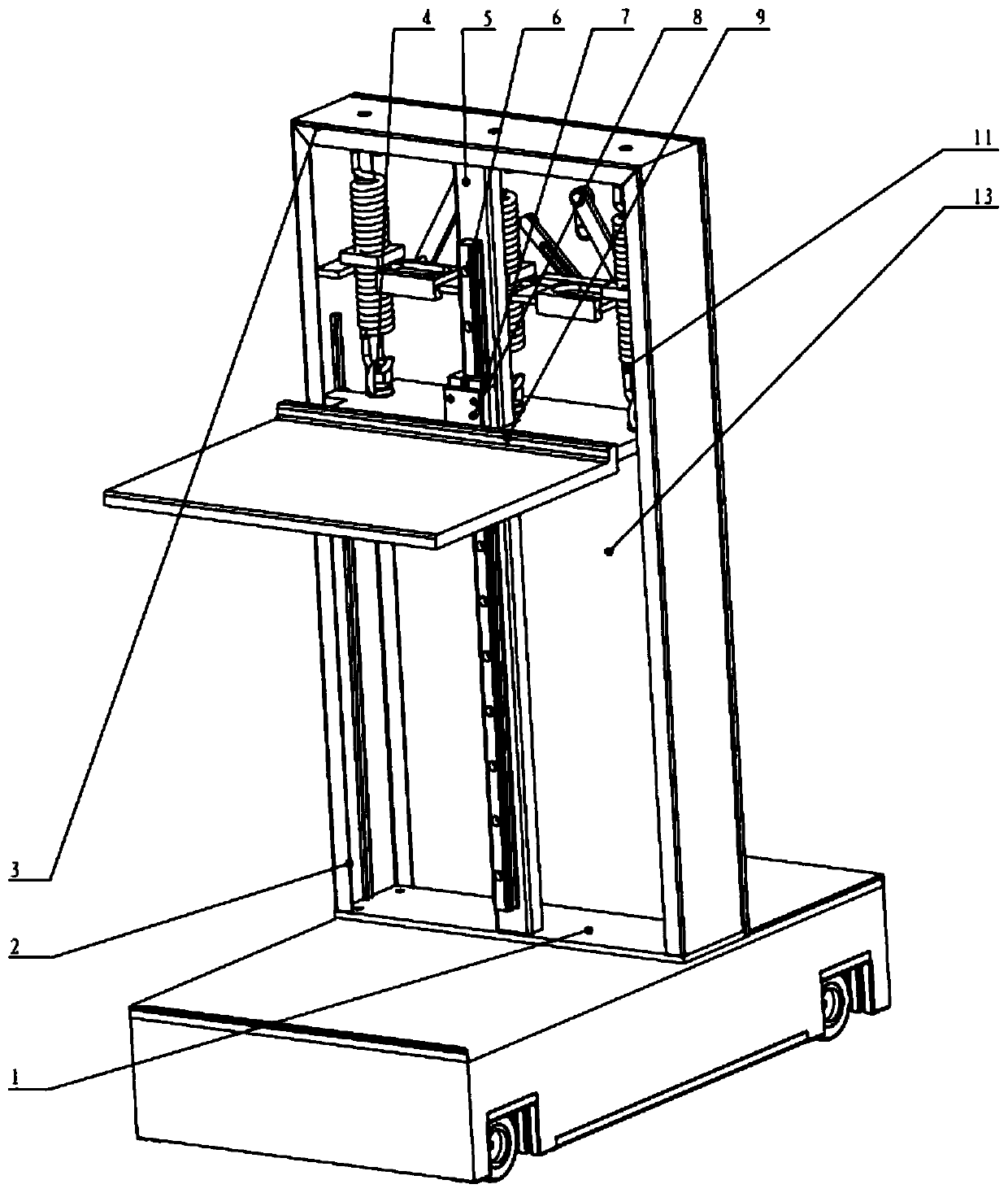

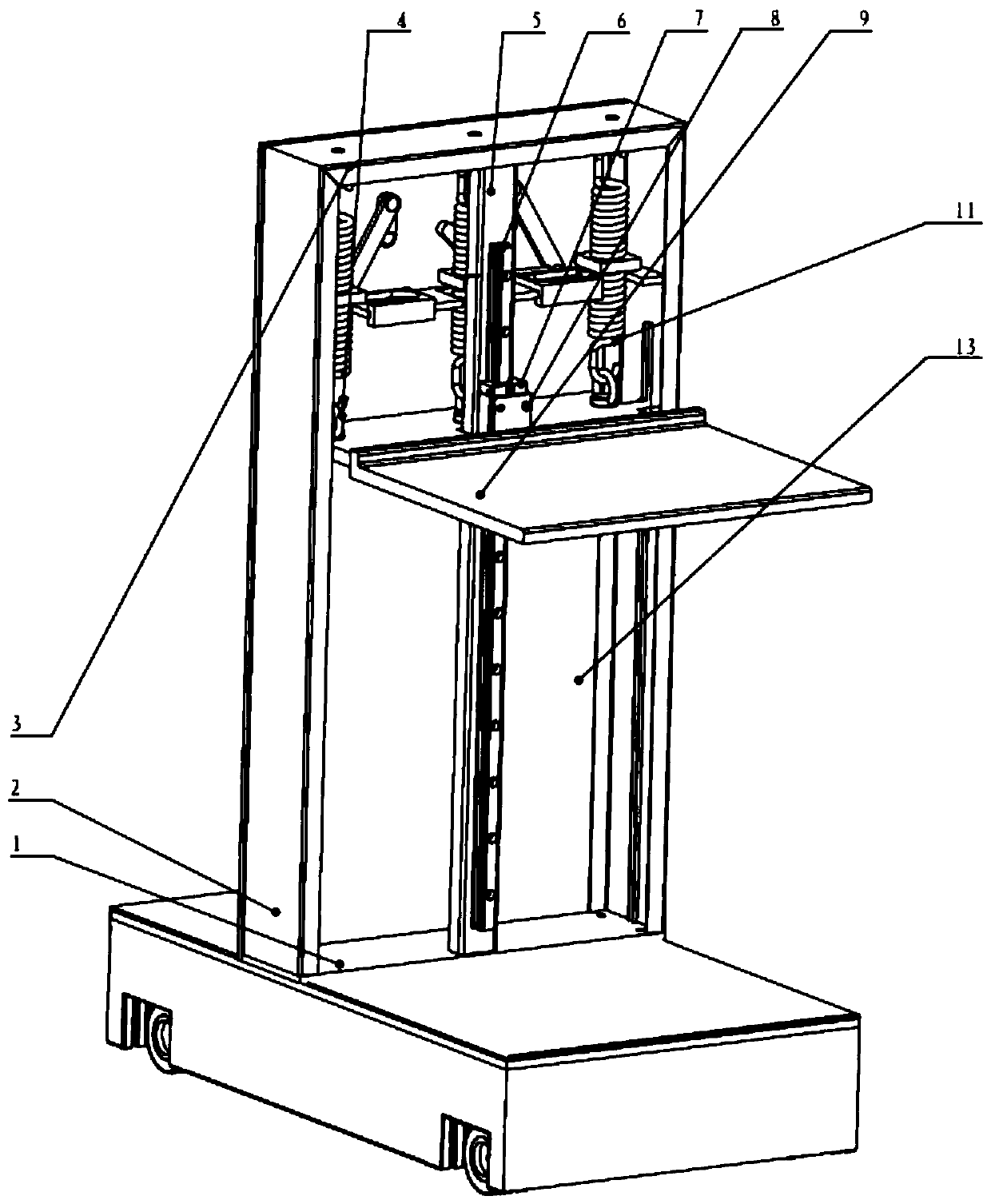

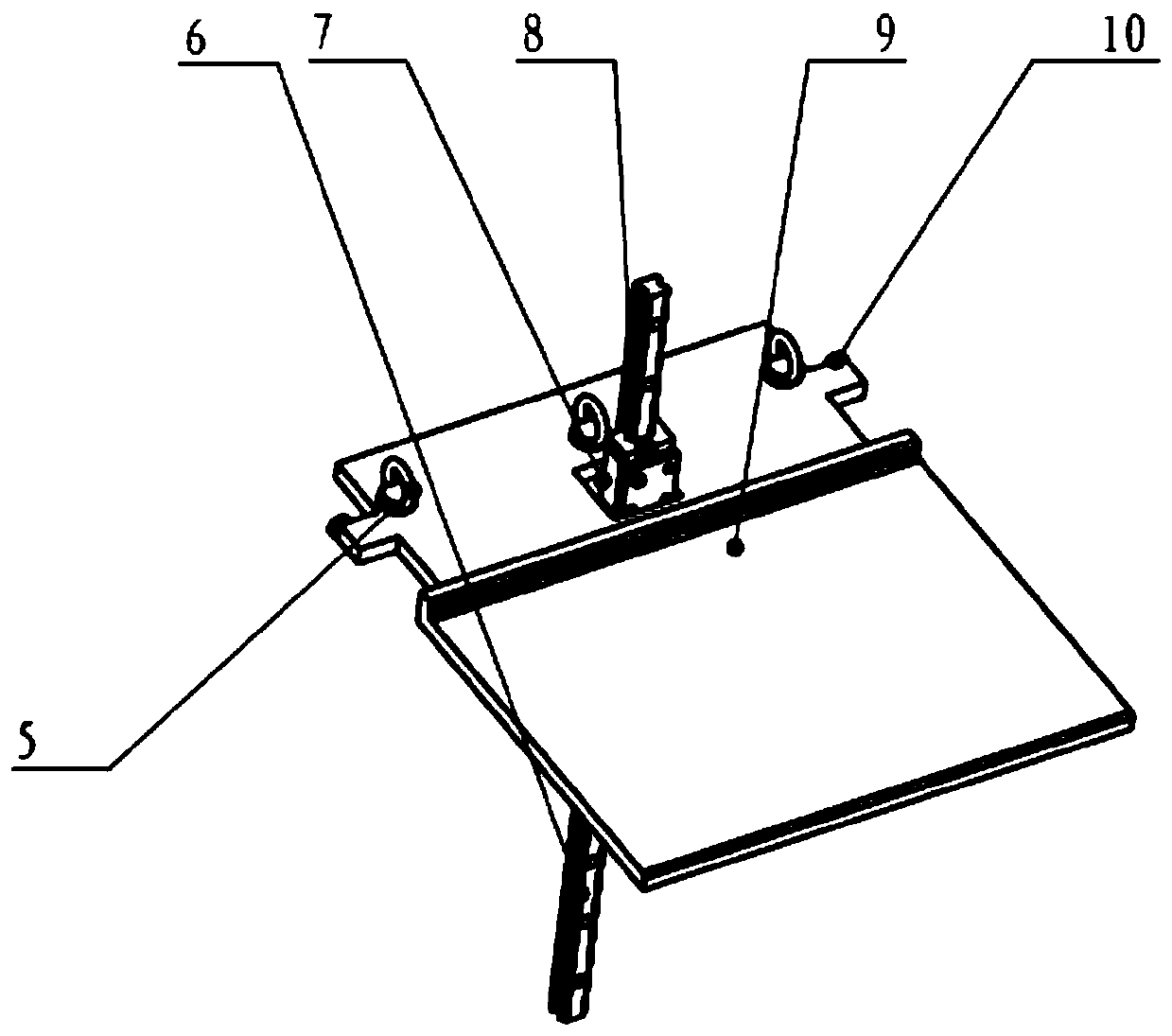

[0024] refer to Figure 1-Figure 2 , this embodiment includes a frame, a loading plate, a combined spring and an adjustment mechanism;

[0025] The frame includes a frame bottom plate 1, a frame side plate 2, a frame top plate 3, a U-shaped channel steel 5, a frame rear plate 13, a frame middle plate 14, a support frame 8, a linear guide rail 6 and a slide block 7 , the frame bottom plate 1 is fixed on the trolley by screws, the frame side plate 2 is welded and fixed on the frame bottom plate 1, the frame top plate 3 is welded and fixed on the frame side plate 2, and the U-shaped Channel steel 5 is welded and fixed between the frame bottom plate 1 and the frame top plate 3, and the frame rear plate 13 is welded and fixed with the frame bottom plate 1, the frame side plate 2, and the frame top plate 3, and the frame middle plate 14 is welded and fixed ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap