Four-linkage lifting omni-directional rotation device

A slewing device, an all-round technology, applied in the direction of support device, earthwork drilling, drilling equipment, etc., can solve the problems of poor mechanism stability, damage to the slewing mechanism, difficult underground transportation and construction, etc., to achieve the effect of easy movement and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following description and drawings sufficiently illustrate specific embodiments of the invention to enable those skilled in the art to practice them. Other embodiments may incorporate structural, logical, electrical, process, and other changes. The examples merely represent possible variations. Individual components and functions are optional unless explicitly required, and the order of operations may vary. Portions and features of some embodiments may be included in or substituted for those of other embodiments.

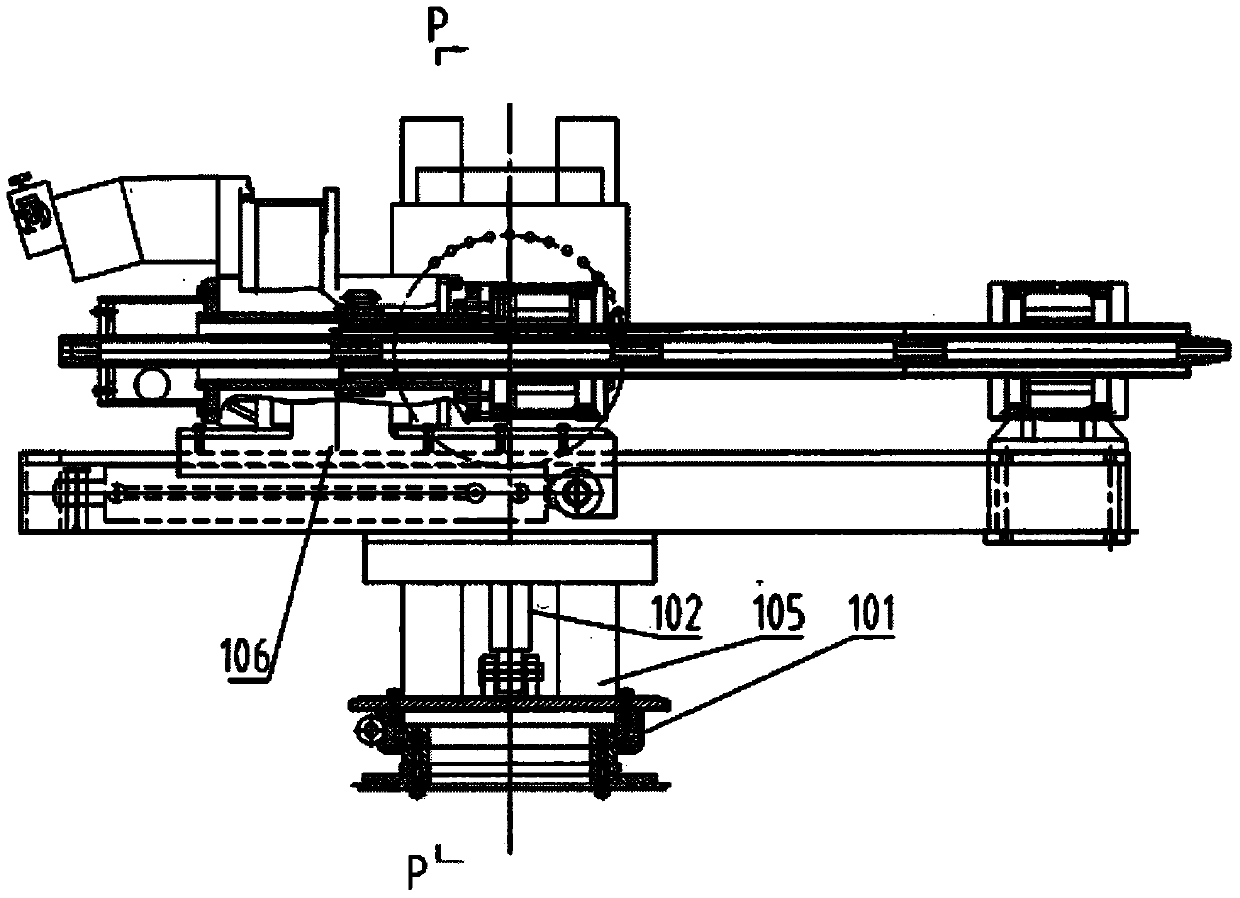

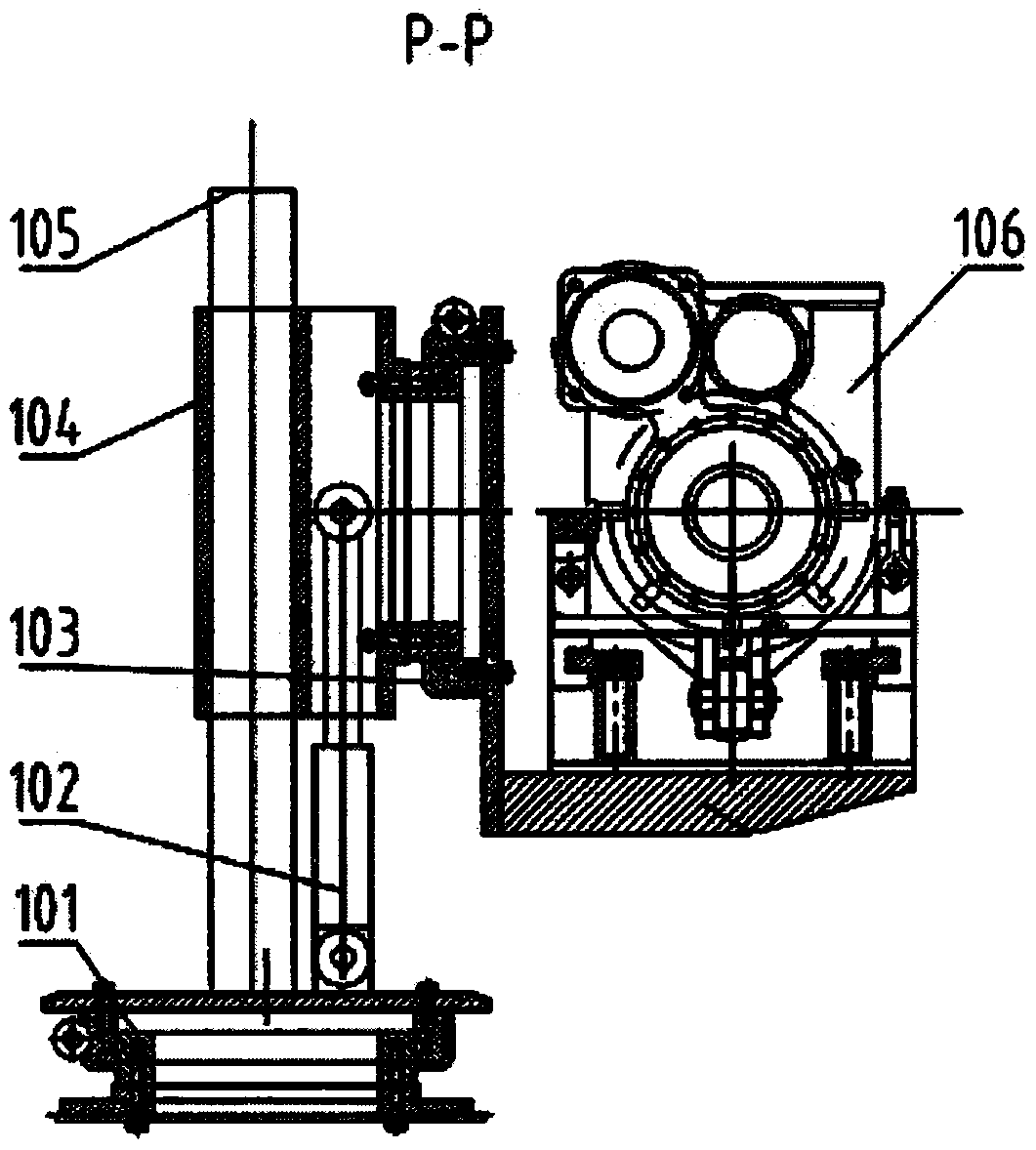

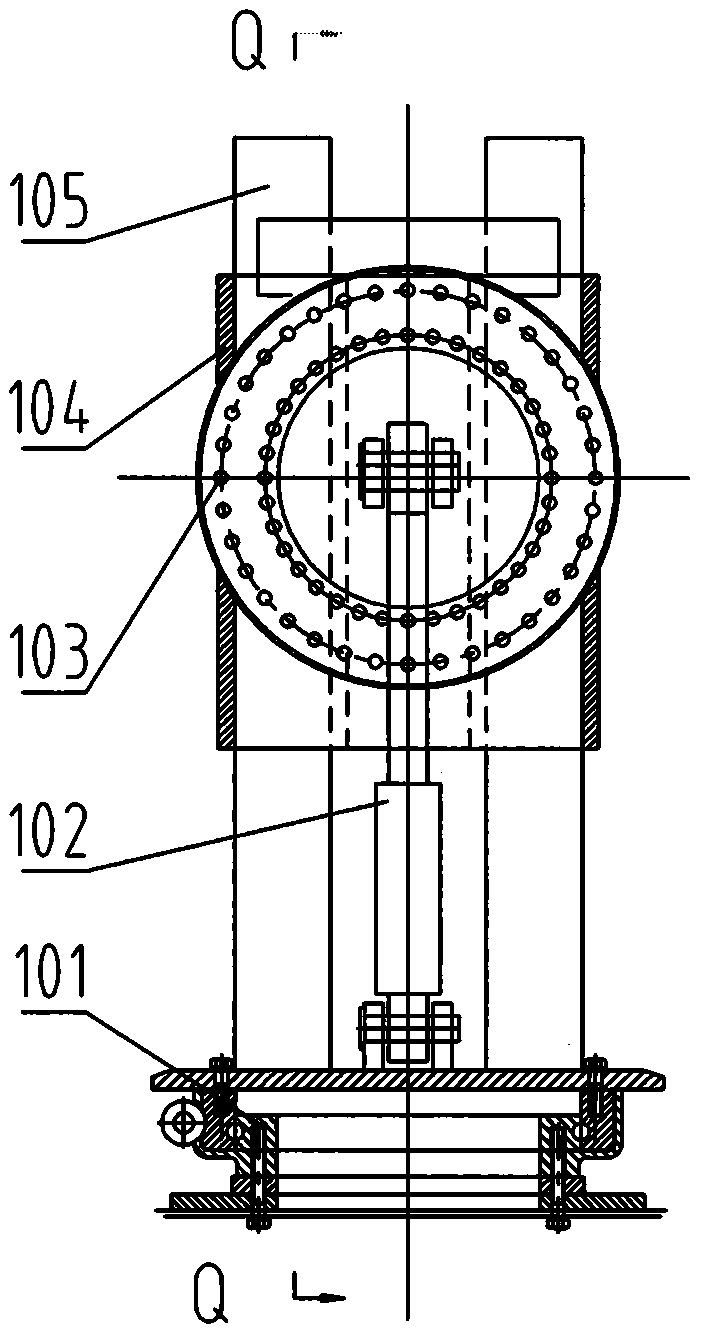

[0029] Such as Figures 5 to 11 As shown, in some demonstrative embodiments, a four-link lifting and omnidirectional turning device is provided, including: a moving beam 1, a moving cylinder 11, a second overturning beam 2, a second overturning beam cylinder 12, a first overturning beam 3. Upper connecting rod 4, front connecting rod 5, rear connecting rod 6, slewing seat 7, a flip beam cylinder 13, lifting cylinder 14, slewing support bearing 8, worki...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap