A variable space π-type shear test device

A shear test, variable space technology, applied in measuring devices, using stable shear force to test the strength of materials, testing of mechanical parts, etc. and other problems, to achieve the effect of eliminating the influence of additional bending moment, convenient installation and disassembly, and convenient test requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

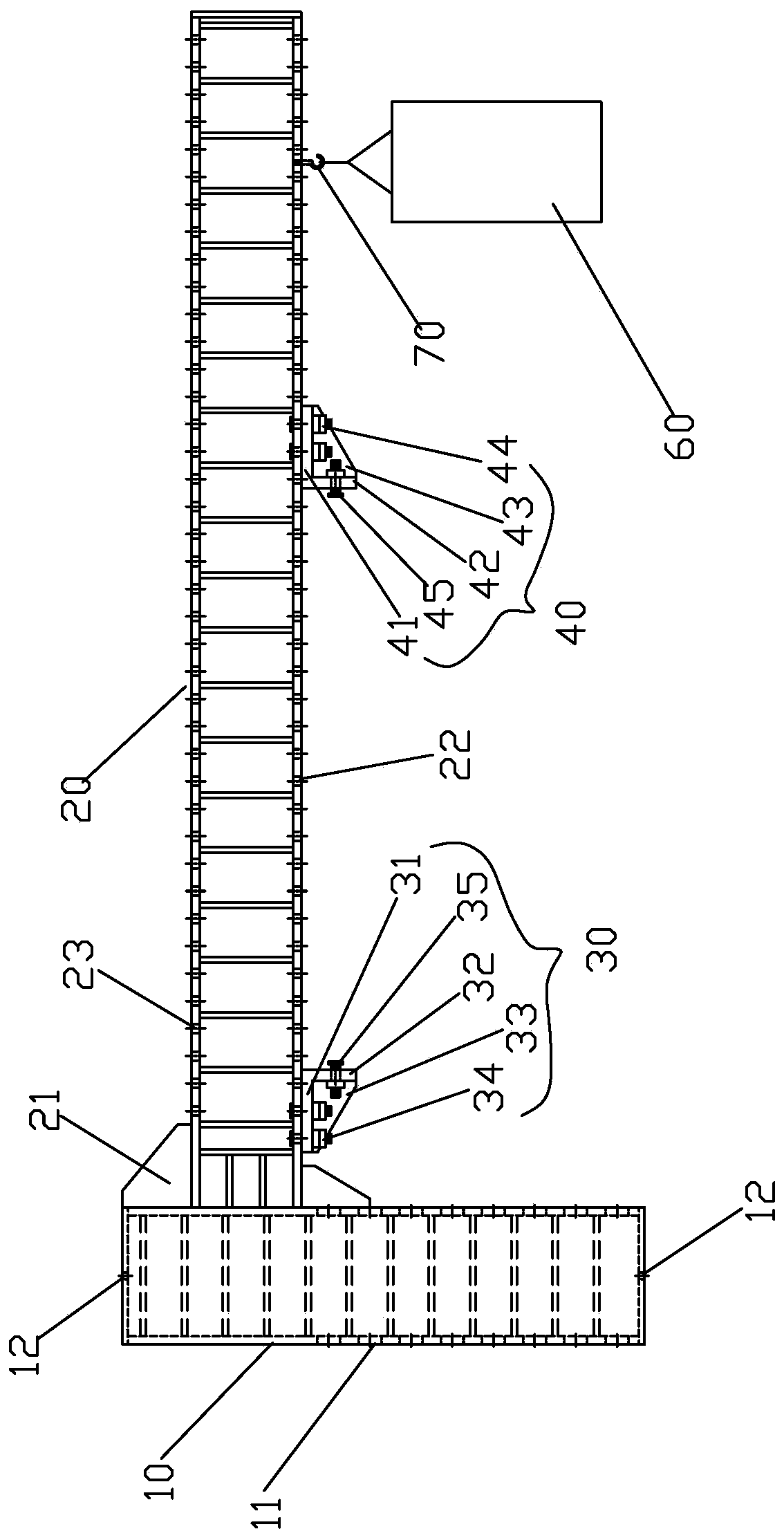

[0040] In order to further explain the technical solution of the present invention, it will be described in detail below in conjunction with the accompanying drawings.

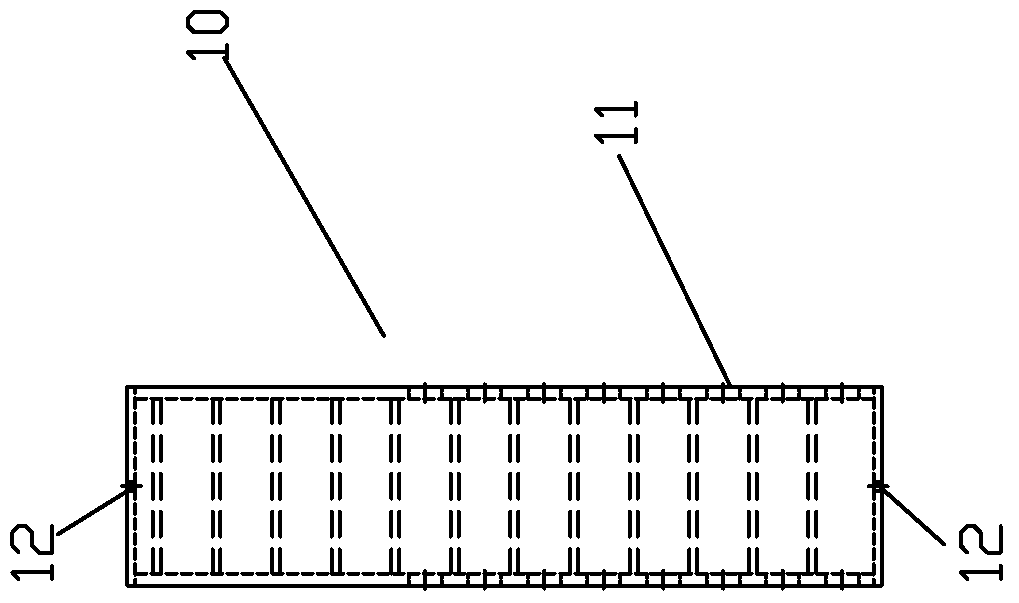

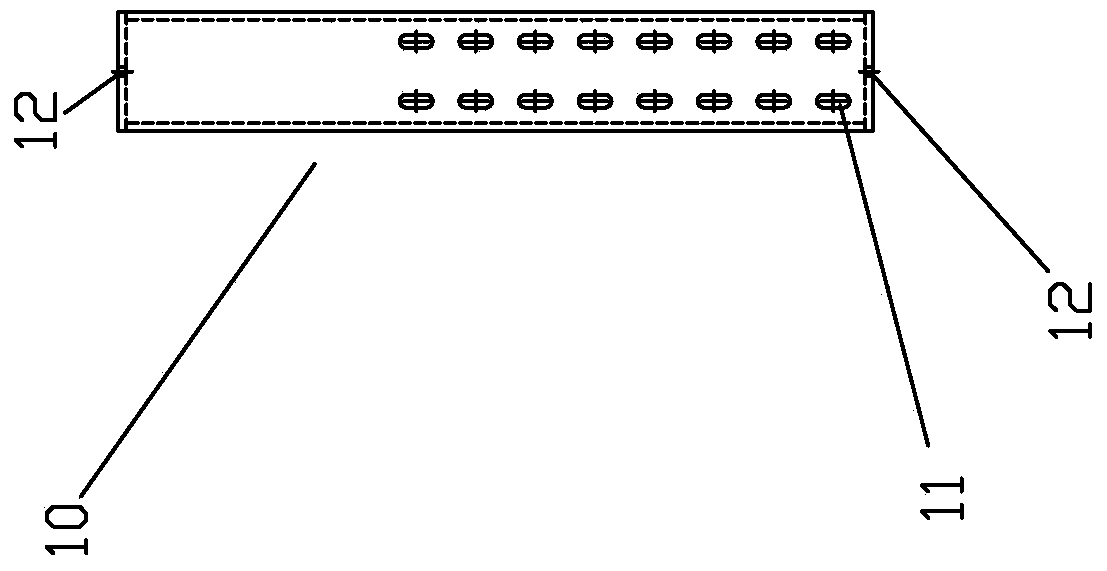

[0041] refer to Figure 1 to Figure 8 , a variable space Π-type shear test device, including a conversion beam 10 connected to a horizontal loading device (not shown in the figure) and a horizontal shear beam 20 connected to a vertical loading device (not shown in the figure), the conversion The beam 10 is arranged in the vertical direction, the horizontal shear beam 20 is arranged in the horizontal direction, the horizontal loading device applies a horizontal force to the transfer beam 10, the vertical loading device loads the vertical force to the horizontal shear beam 20, and the horizontal loading device The vertical loading device and the vertical loading device are conventional devices in the field of component performance testing, and will not be described in detail here.

[0042] In the present invent...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap