Tearing-assistant device for elevator protection film

A technology of auxiliary device and protective film, applied in the directions of lamination auxiliary operation, layered products, lamination, etc., can solve the problems of inconvenient operation, inability to adjust the operating handle, softening of the inner layer glue without protective film, etc., to avoid scratches , Improve the tearing efficiency, the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

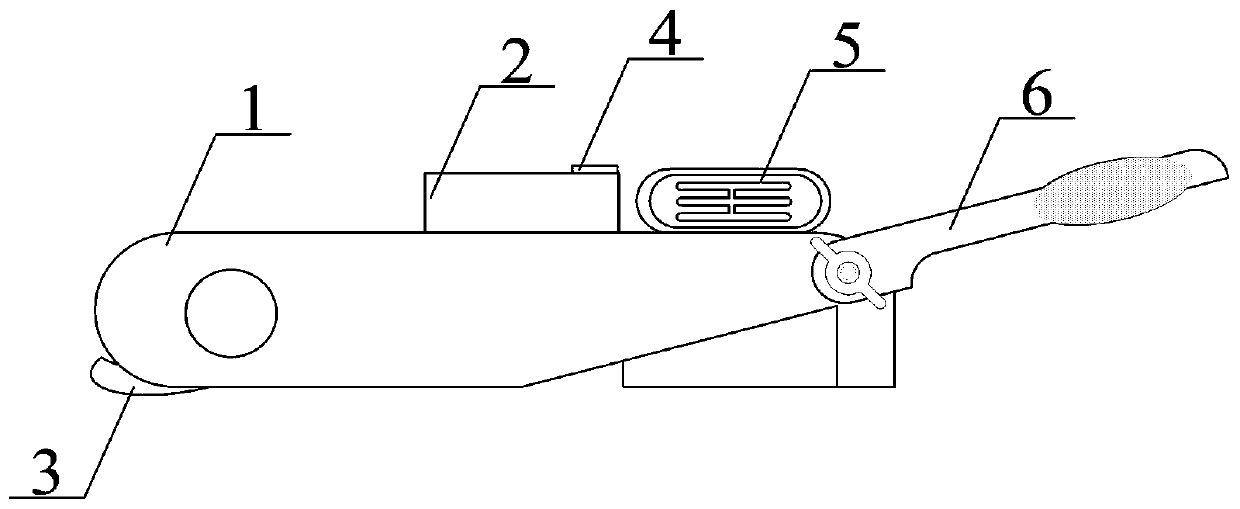

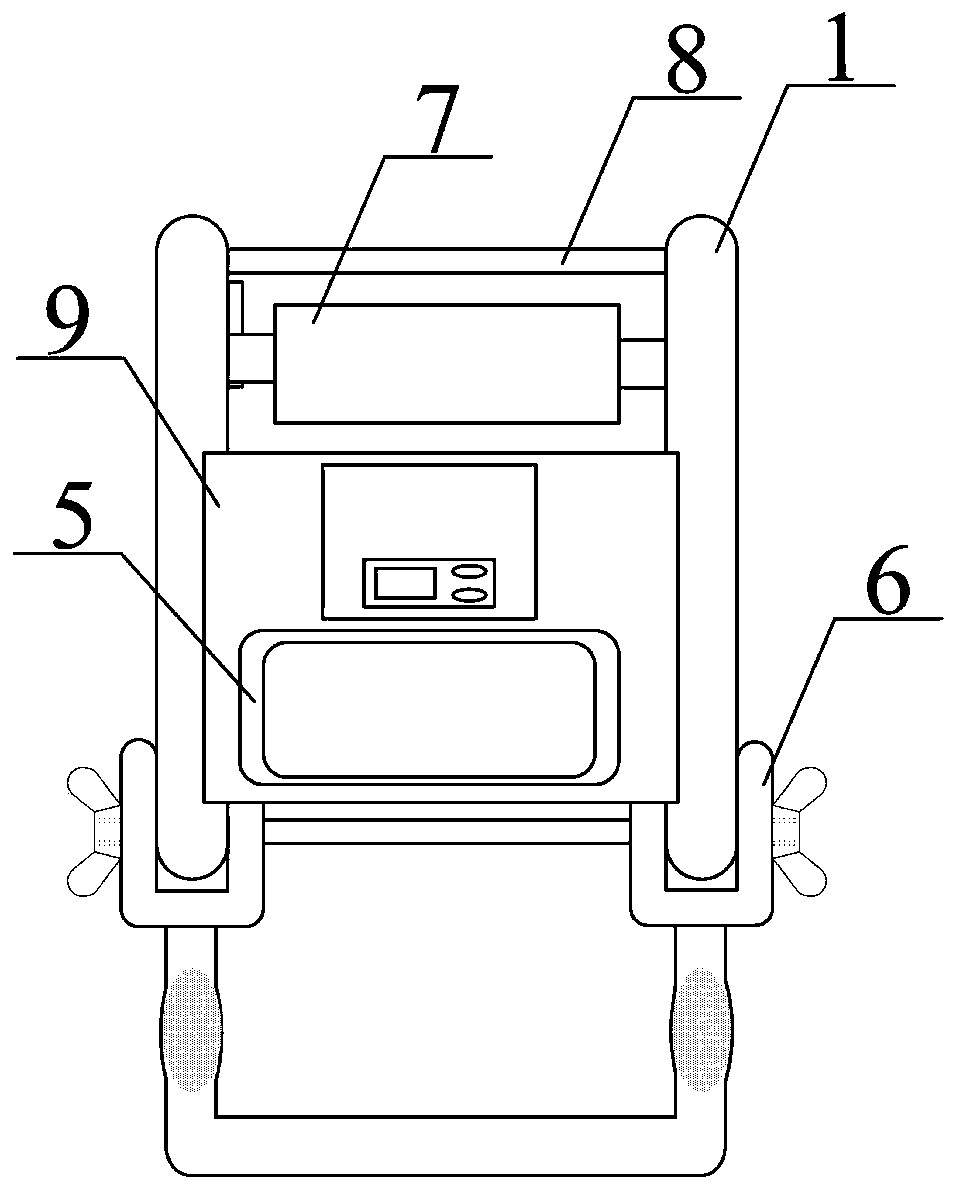

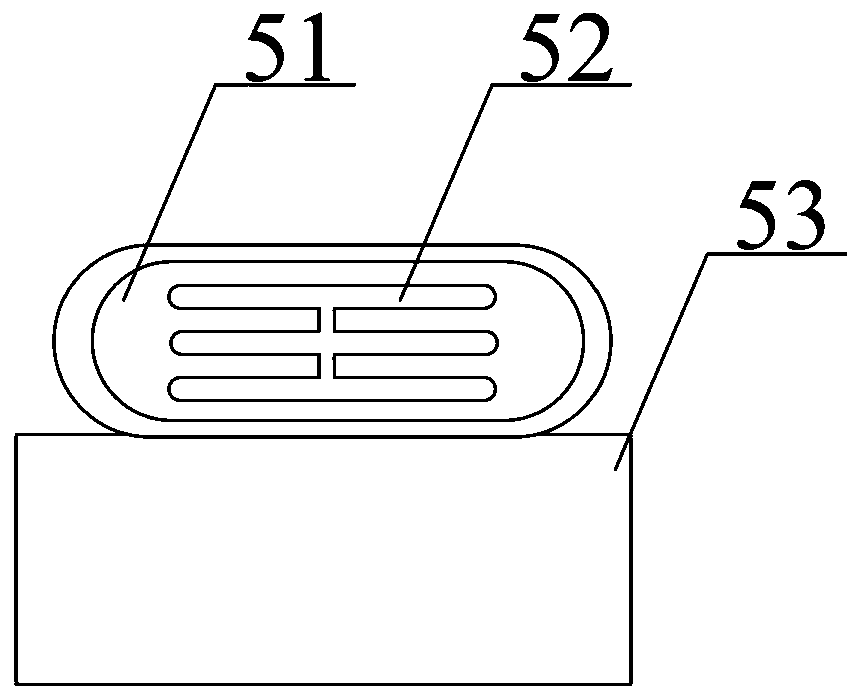

[0024] as attached figure 1 to attach Figure 5 shown

[0025] The present invention provides an elevator protective film tearing auxiliary device, which includes a frame body 1, a battery 2, an electric heating knife 3, a control panel 4, a heating mechanism 5, an adjustment handle 6, a delivery roller 7, a scraper 8 and a top plate 9, The battery 2 is embedded on the top of the top plate 9, and a protective casing is installed on the outside; the electric knife 3 is installed on the inside of the frame body 1 by screws, and is connected with the battery 2 and the control panel 4 by wires; the control The panel 4 is arranged on the upper end of the protective shell of the storage battery 2, and is connected with the storage battery 2 through wires; the heating mechanism 5 is embedded in the right end of the frame body 1, and is respectively connected with the storage battery 2 and the control panel 4 through wires; the adjustment handle 6 is movably installed at one end of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap