A cell module casing device

A cell module and cell technology, applied in the field of cell module housing device, can solve the problems of uneven pressure inlet, uneven deformation, easy deformation, etc., to save the number of cells, ingenious design, practical strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with specific embodiment, the content of the present invention is described in further detail:

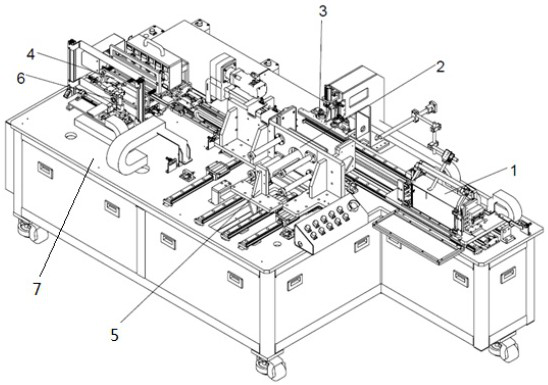

[0024] like figure 1 As shown in the figure, the problem to be solved by the present invention is to provide a device for inserting a cell module into a casing with a compact structure and stable operation, and the device includes:

[0025] Rack 7, housing fixing device 1, cell entering device 2, cell fixing device 4;

[0026] The casing fixing device 1 is fixed at the front end of the frame 7; the two sides of the casing fixing device 1 are provided with clamping cylinders 15; the battery cell entering device 2 is arranged in the middle of the frame 7; The cell fixing device 4 is arranged at the rear end of the rack 7; the rack 7 is provided with a guide rail 8; Device 4 is connected.

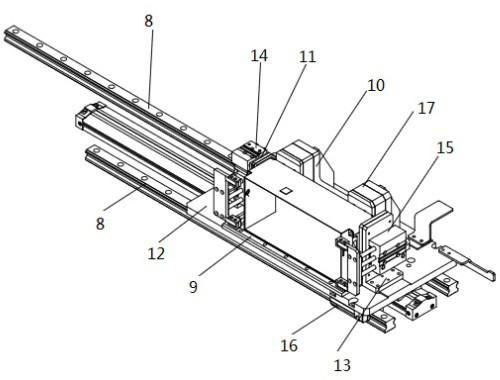

[0027] like figure 2 As shown, further, the casing fixing device 1 is covered with a casing positioning plate 9, a module base plate 10, a movable cylinder push pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com