Filter device

A filtration equipment and filter technology, applied in filtration separation, membrane filter, fixed filter element filter, etc., can solve problems such as mud clogging, and achieve the effect of effective cleaning, reduced pressure loss, and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

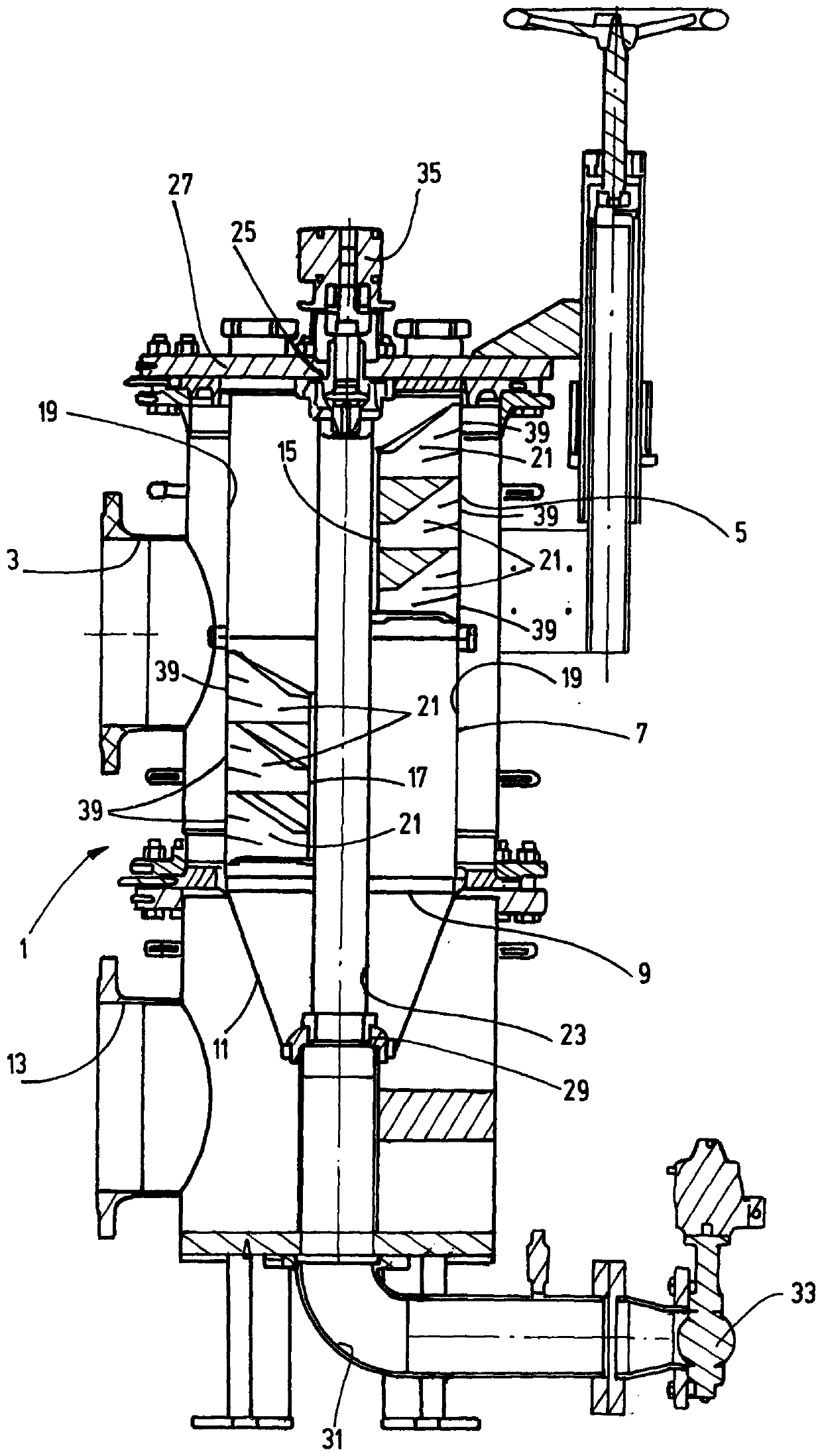

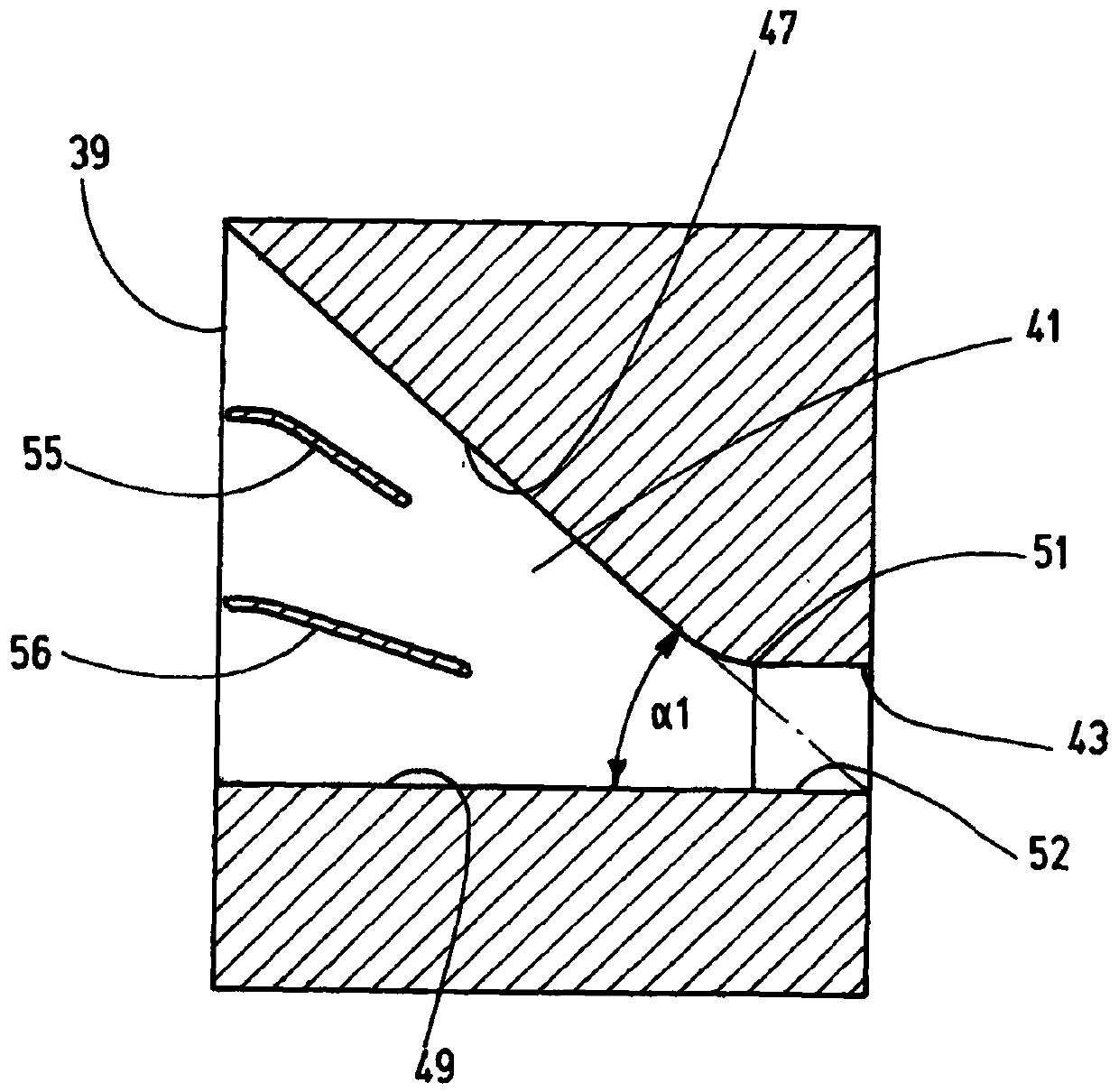

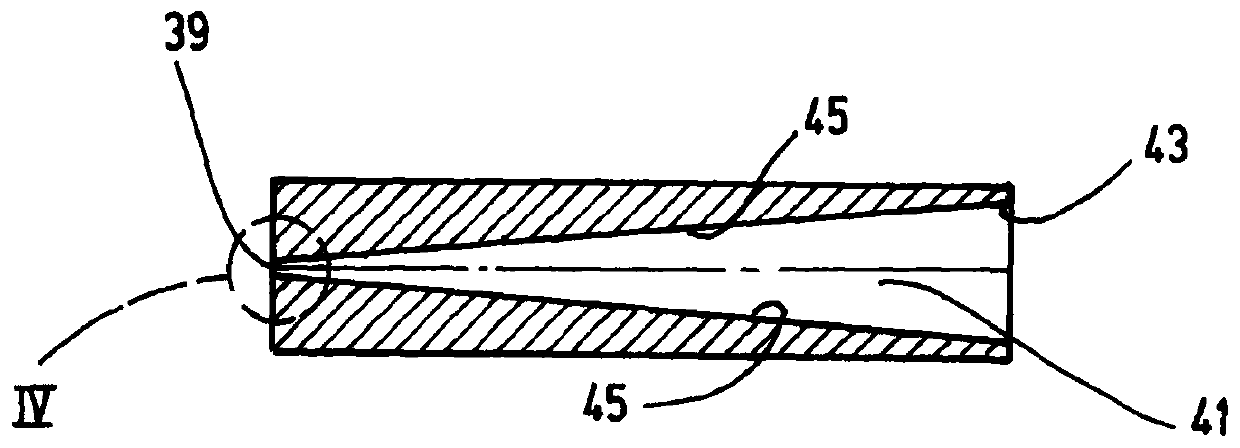

[0047] exist figure 1 An exemplary embodiment of a filter device according to the invention is shown in , wherein the filter housing as a whole is marked with 1 . A fluid outlet 3 for the filtrate is arranged laterally on the cylindrical filter housing 1 . An upper filter insert 5 and a lower filter insert 7 are accommodated in a superimposed arrangement in the filter housing 1 , through which filter inserts can flow through from the inside to the outside during the filtration process, wherein unfiltrate can be supplied to both filter inserts from the lower inlet side 9 5 and 7. Connected upstream of the inlet side 9 is an inlet filter 11 as a prefilter, through which unfiltrate can be conveyed through an inlet 13 for unfiltrate. In nautical applications, the input filter 11 is arranged as a so-called fish screen.

[0048] In order to clean deposits on the filter material 19 of the upper filter element 5 and the lower filter element 7 during backwashing, a backwashing arm 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com