Manufacturing method of cover, molded article, and mold for molding

A manufacturing method and technology of molded products, applied in medical science, hospital beds, hospital equipment, etc., can solve problems such as lack of molded products, poor transferability, etc., and achieve the effect of suppressing the increase in manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

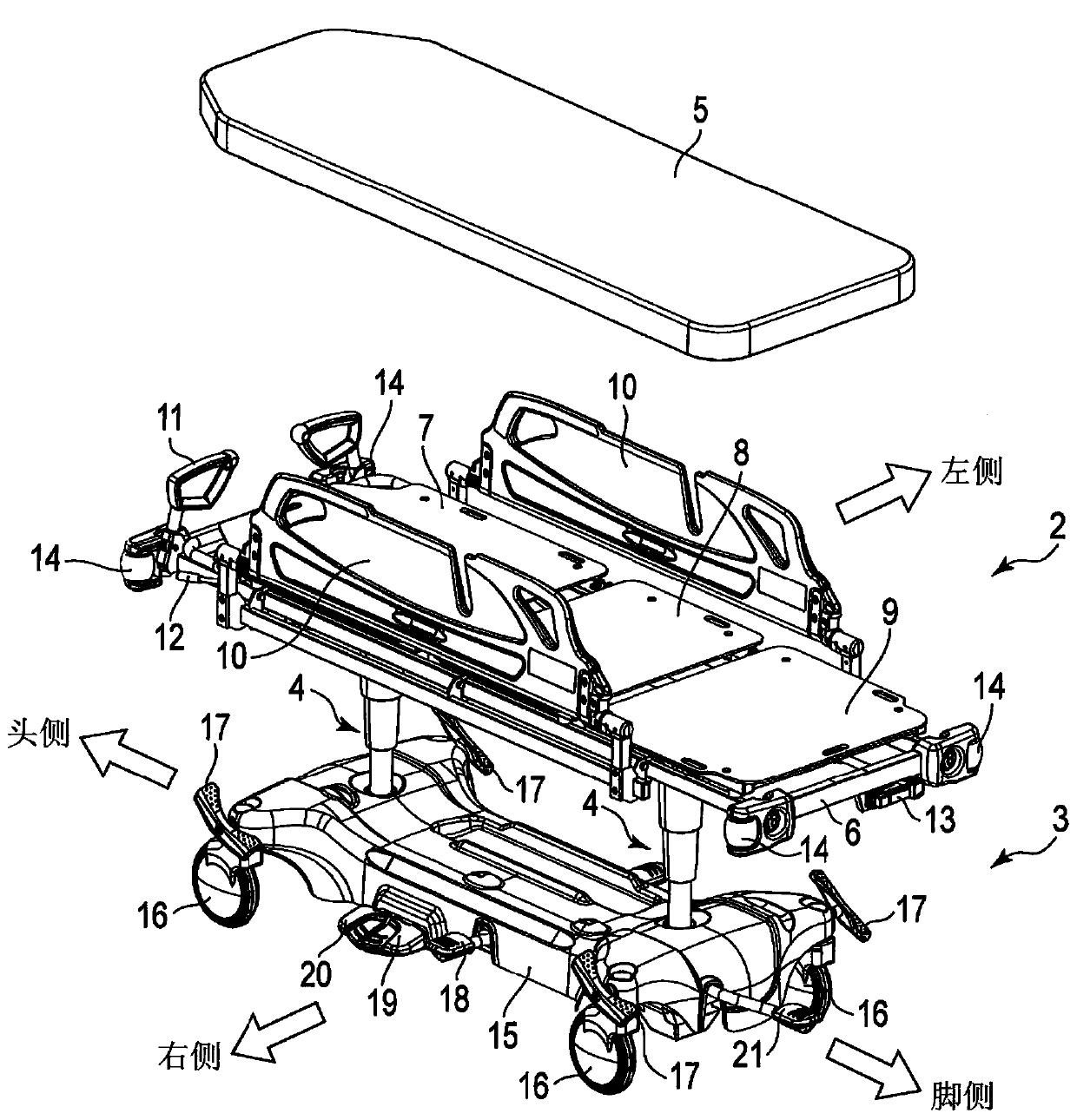

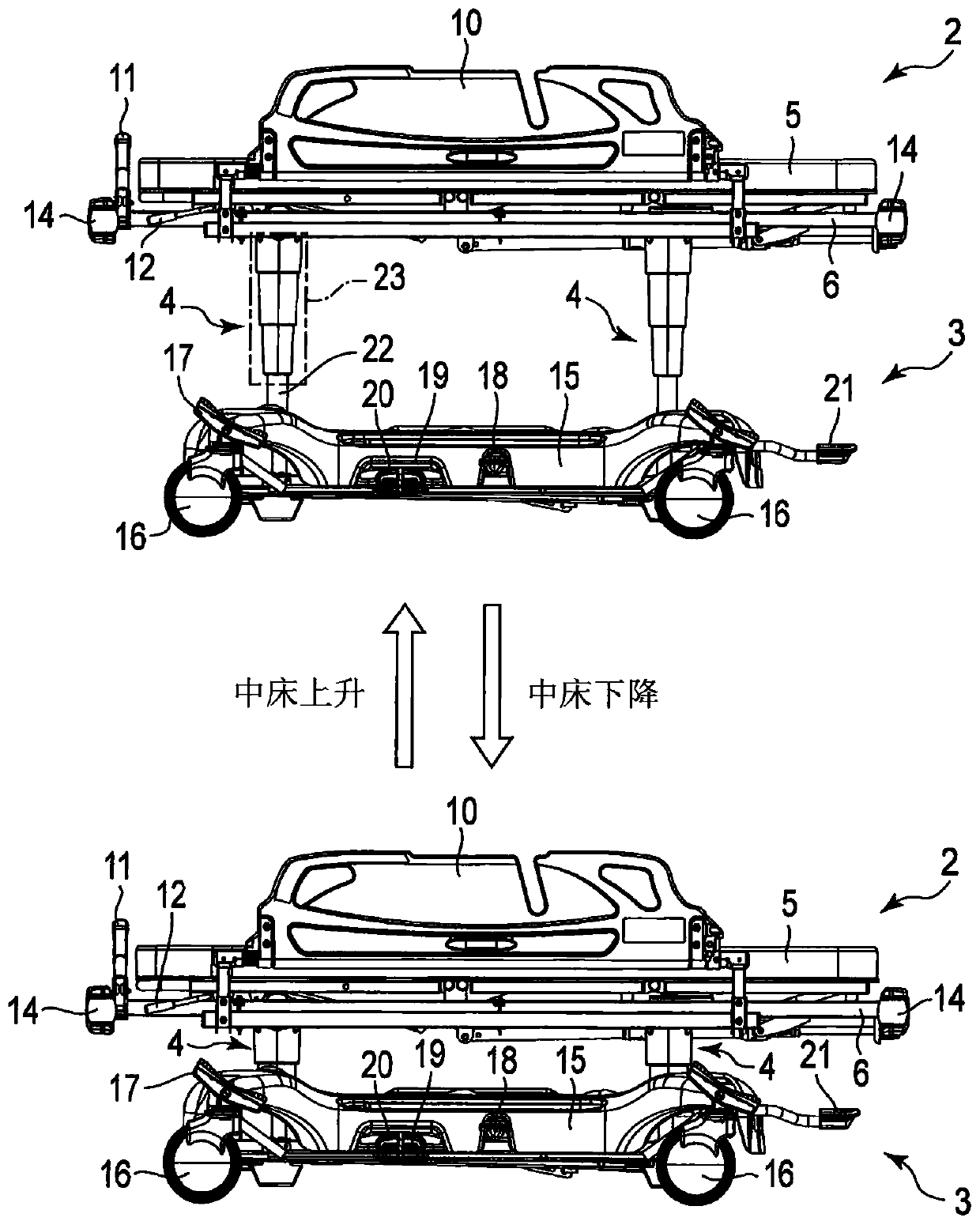

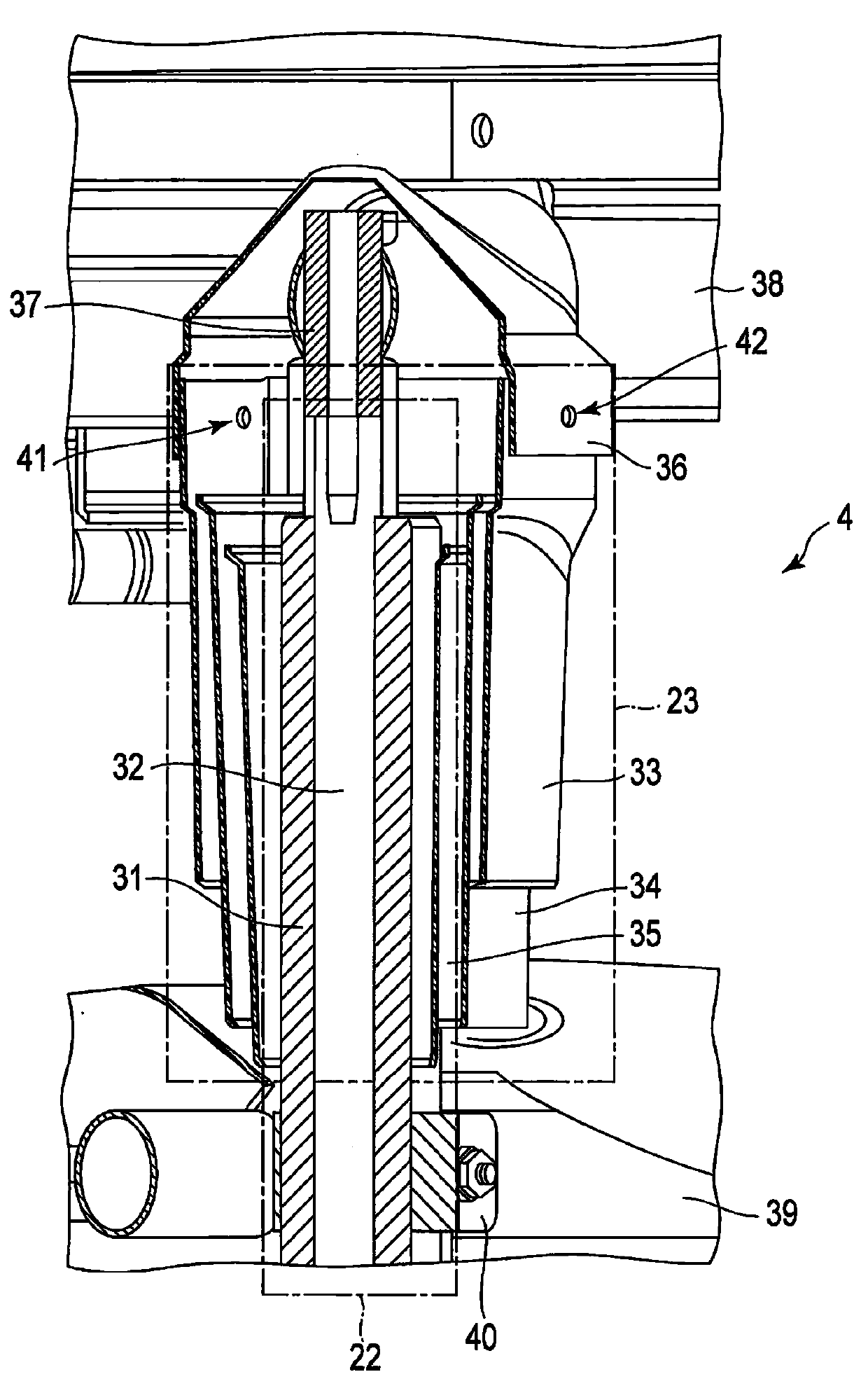

[0081] The method of manufacturing the cover, the molded product, and the mold for molding of the first embodiment will be described. Hereinafter, an example in which a telescoping cover is used for a lifting device of a stretcher having a lifting function will be described. In addition, the telescoping cover is not limited to stretchers, and can also be applied to other bed devices with lifting functions such as medical beds, nursing beds, operating tables, and newborn beds, and can also be applied to tables, chairs, etc. Products with lifting function.

[0082] 1.1 Stretcher structure

[0083] First, use figure 1 and figure 2 The overall structure of the stretcher 1 will be described. figure 1 A perspective view of the stretcher 1 is shown. figure 2 It is a diagram showing the raising and lowering operation of the stretcher 1, showing the state in which the middle bed 2 (bed portion) of the stretcher 1 is raised most (hereinafter referred to as "highest position") and...

no. 2 approach

[0170] Next, a second embodiment will be described. In the second embodiment, a description will be given of a case where a shape serving as a guide for a cutter or the like is provided when cutting is performed at the cutting position of the molded product 100 .

[0171] 2.1 Sectional shape of molded product

[0172] use Figure 12 Next, the cross-sectional shape of the molded product 100 will be described. Figure 12 with the first embodiment Figure 9 Similarly, in the molded article 100 of the present embodiment, an enlarged view of a region AR near the cross section of the second cutting portion 103 is shown.

[0173] Such as Figure 12 As shown, the molded product 100 in this embodiment has a concave guide portion 112 a corresponding to the second cutting position 112 and a concave guide portion 113 a corresponding to the third cutting position 113 . In addition, in Figure 12 In the example shown, there are guide parts 112a and 113a, but the molded product 100 has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com