Stator for rotary electric machine

A technology for rotating electrical machines and stators, applied to the shape/style/structure of winding conductors, which can solve the problems of difficulty in satisfying the positional accuracy of multiple fastening parts, insufficient joint strength, and increased manufacturing costs to achieve guaranteed joints Effects of strength, suppression of increase in manufacturing cost, and suppression of increase in the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] Hereinafter, an embodiment of a stator of a rotating electrical machine according to the present invention will be described based on the drawings. It should be noted that the drawings are viewed along the direction of the symbols.

[0078] [stator]

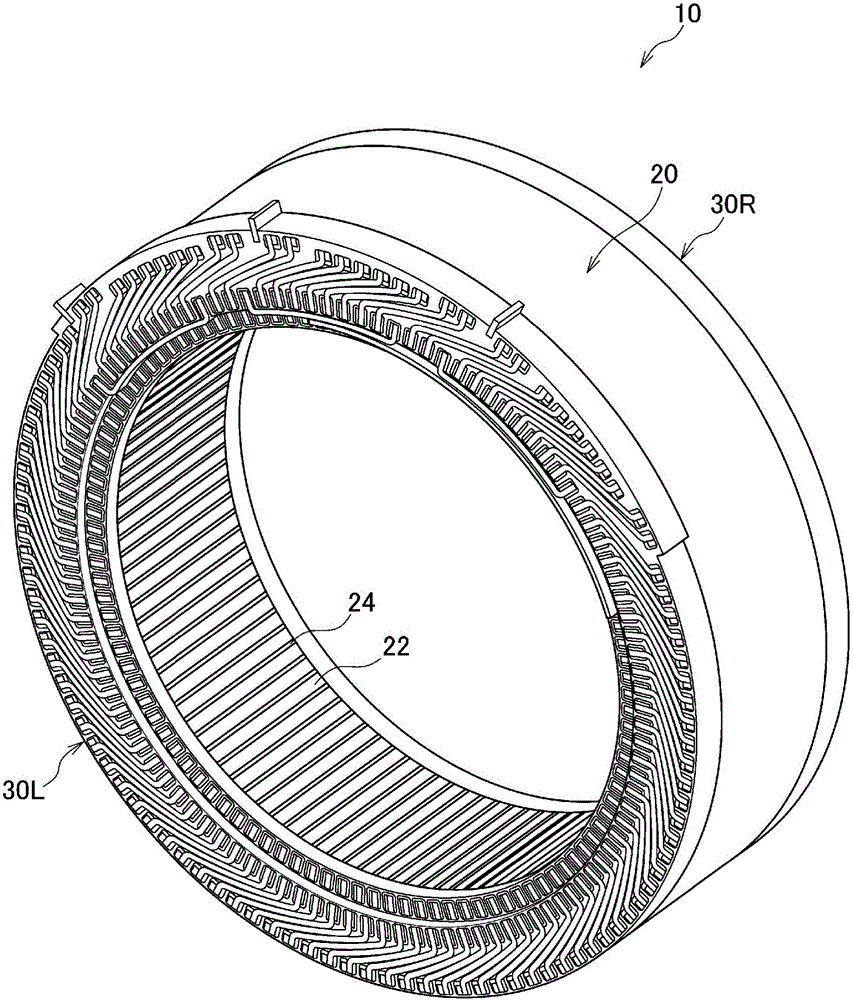

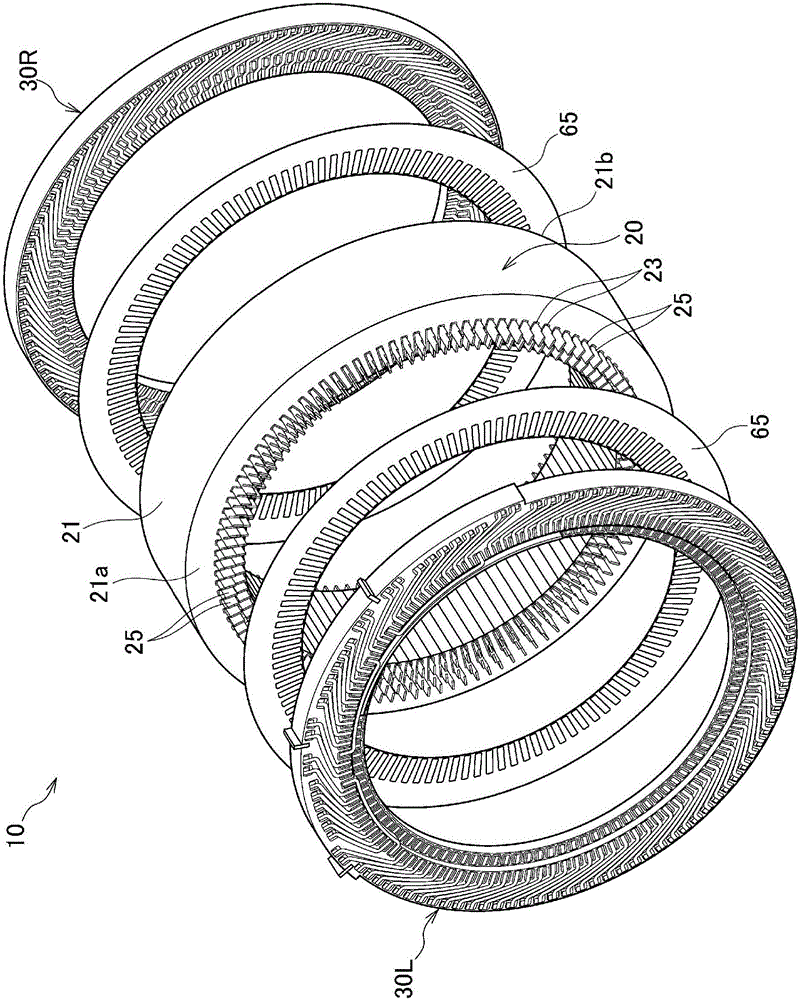

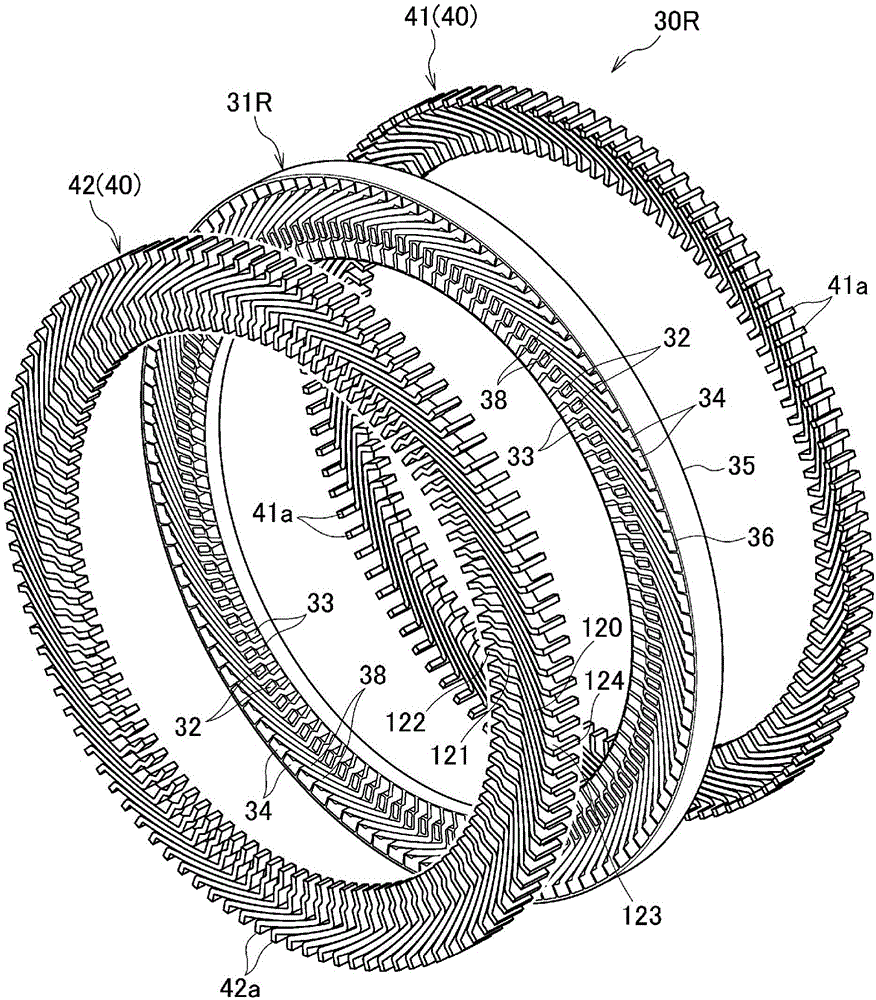

[0079] Such as figure 1 and figure 2 As shown, the stator 10 of the rotating electrical machine according to this embodiment includes a stator core assembly 20 and a pair of base plate assemblies 30L, 30R. The base plate assemblies 30L, 30R are arranged and assembled on both sides of the stator core assembly 20 . An insulating sheet 65 such as a silicon wafer is arranged between the stator core assembly 20 and the base plate assemblies 30L, 30R to insulate the stator core assembly 20 and the base plate assemblies 30L, 30R.

[0080] [1 stator core assembly]

[0081] The stator core assembly 20 includes a stator core 21 and a plurality (108 in the illustrated embodiment) of slot coils 25 .

[0082] [1-1 stator core]

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com