Compressor And Method For Manufacturing Compressor

A manufacturing method and compressor technology, which is applied in the field of compressors, can solve problems such as deformation and deformation of airtight containers, and the decrease in reliability of compression units in airtight containers, and achieve the effect of suppressing the increase in manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

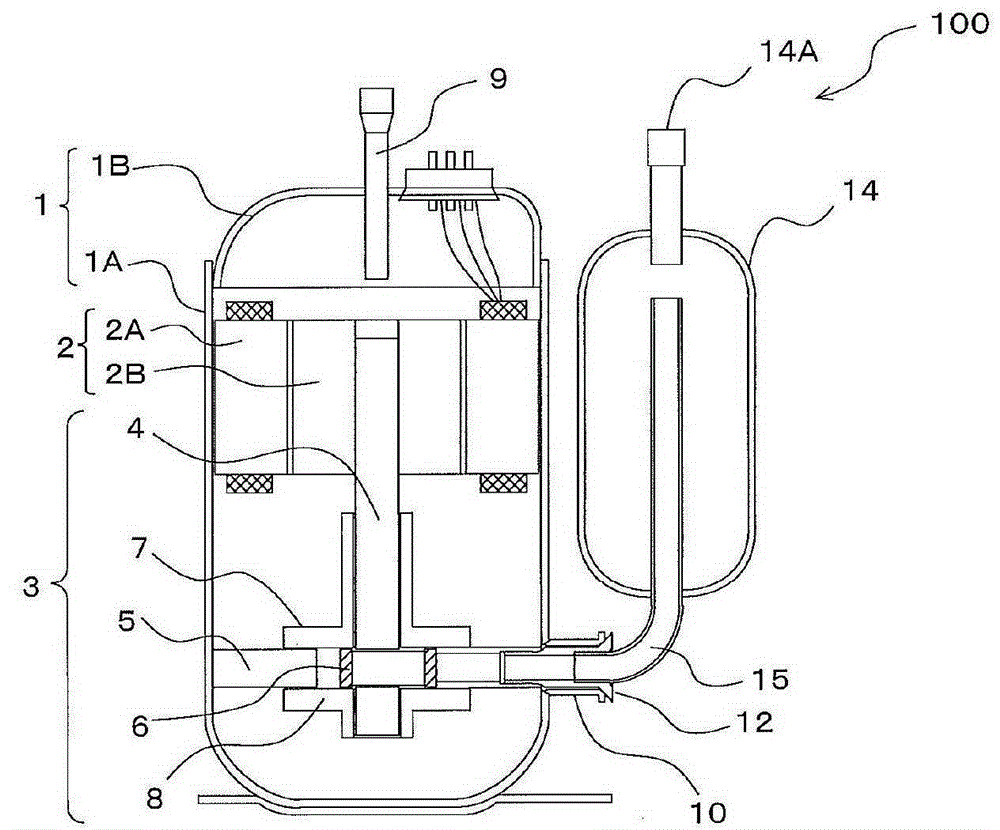

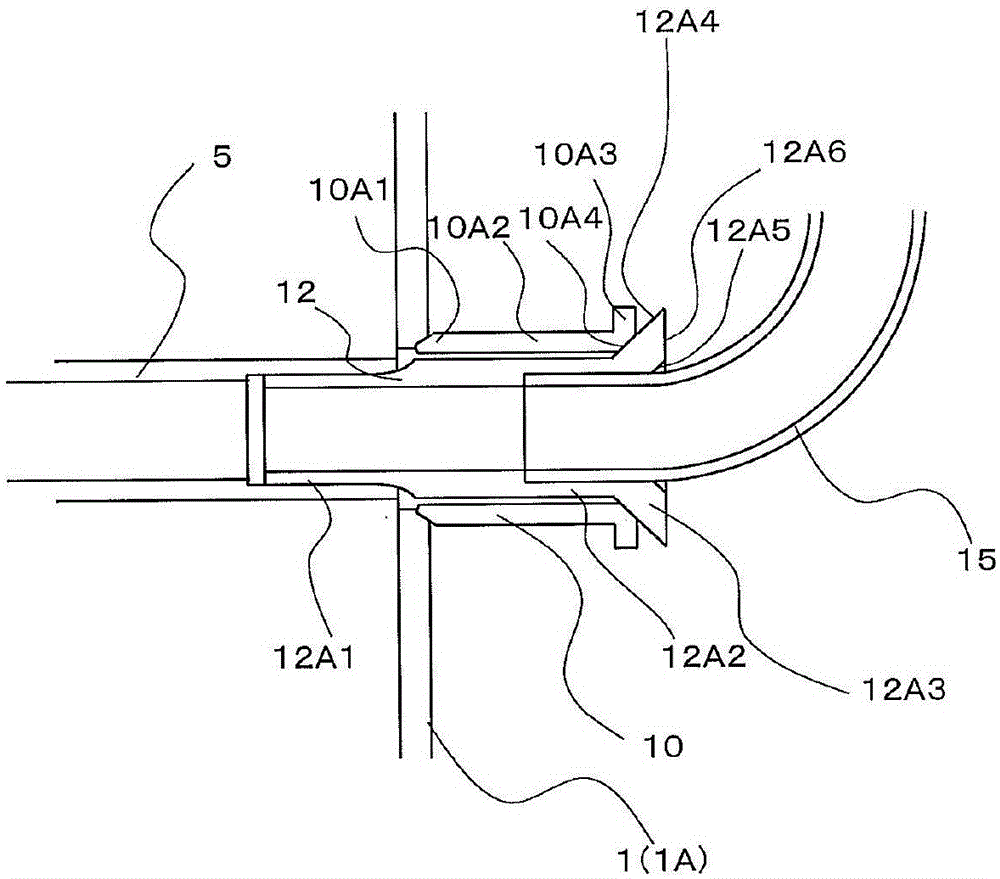

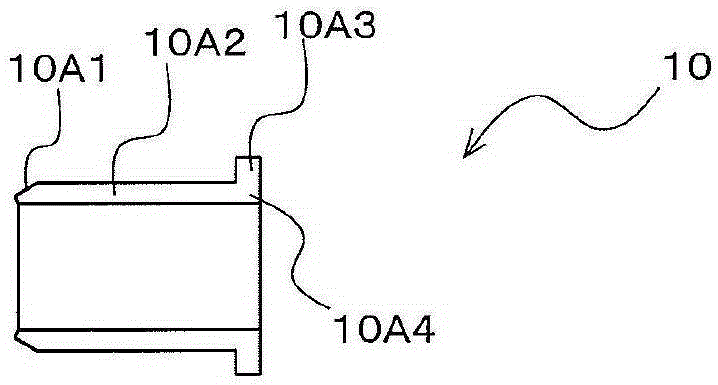

[0047] figure 1 It is a sectional view schematically showing the structure of the compressor 100 according to the first embodiment. figure 2 is schematically shown figure 1 A cross-sectional view of the engagement of the suction connection pipe 12 and the junction pipe 10 of the compressor 100 is shown. Figure 3A ~ Figure 3D It is a schematic diagram explaining the structure of the junction pipe 10 etc., and the 1st welding part P. FIG. refer to figure 1 , figure 2 , Figure 3A ~ Figure 3D The configuration of the compressor 100 will be described. also, figure 1 , figure 2 , Figure 3A ~ Figure 3D It is a longitudinal sectional view of various structures.

[0048] [Structure description]

[0049] Such as figure 1 As shown, the compressor 100 has: a closed container 1; an electric unit 2; a compression unit 3; and an accumulator 14 for accumulating liquid refrigerant. In addition, the compressor 100 has a junction pipe 10 connected to the airtight container 1 , ...

Embodiment approach 2

[0116] Figure 7 It is a cross-sectional view schematically showing the connection between the suction connecting pipe 120 and the joint pipe 110 of the compressor 100 according to the second embodiment. Figure 8A It is a schematic diagram explaining the structure of the joint pipe 110 . Figure 8B It is a schematic diagram explaining the structure of the suction connection pipe 120. refer to Figure 7 , Figure 8A as well as Figure 8B Compressor 100 according to Embodiment 2 will be described. In addition, in this Embodiment 2, the same code|symbol is attached|subjected to the structure common to Embodiment 1, and it demonstrates centering on a difference.

[0117] In Embodiment 1, the first welded portion P is formed on the contact surface between the inner diameter corner portion 10A4 of the joint pipe 10 and the tapered portion 12A4 of the suction connection pipe 12 . On the other hand, in Embodiment 2, instead of forming the inner diameter corner portion 10A4 in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com