Mounting structure, electrooptic device, and electronic apparatus

An electro-optical device and structure technology, applied in the direction of fixed capacitor dielectric, printed circuit assembled with electrical components, printed circuit connected with non-printed electrical components, etc., can solve problems such as harsh noise, environmental deterioration, and downgrade of electronic equipment , achieve the effect of suppressing the increase of manufacturing cost and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

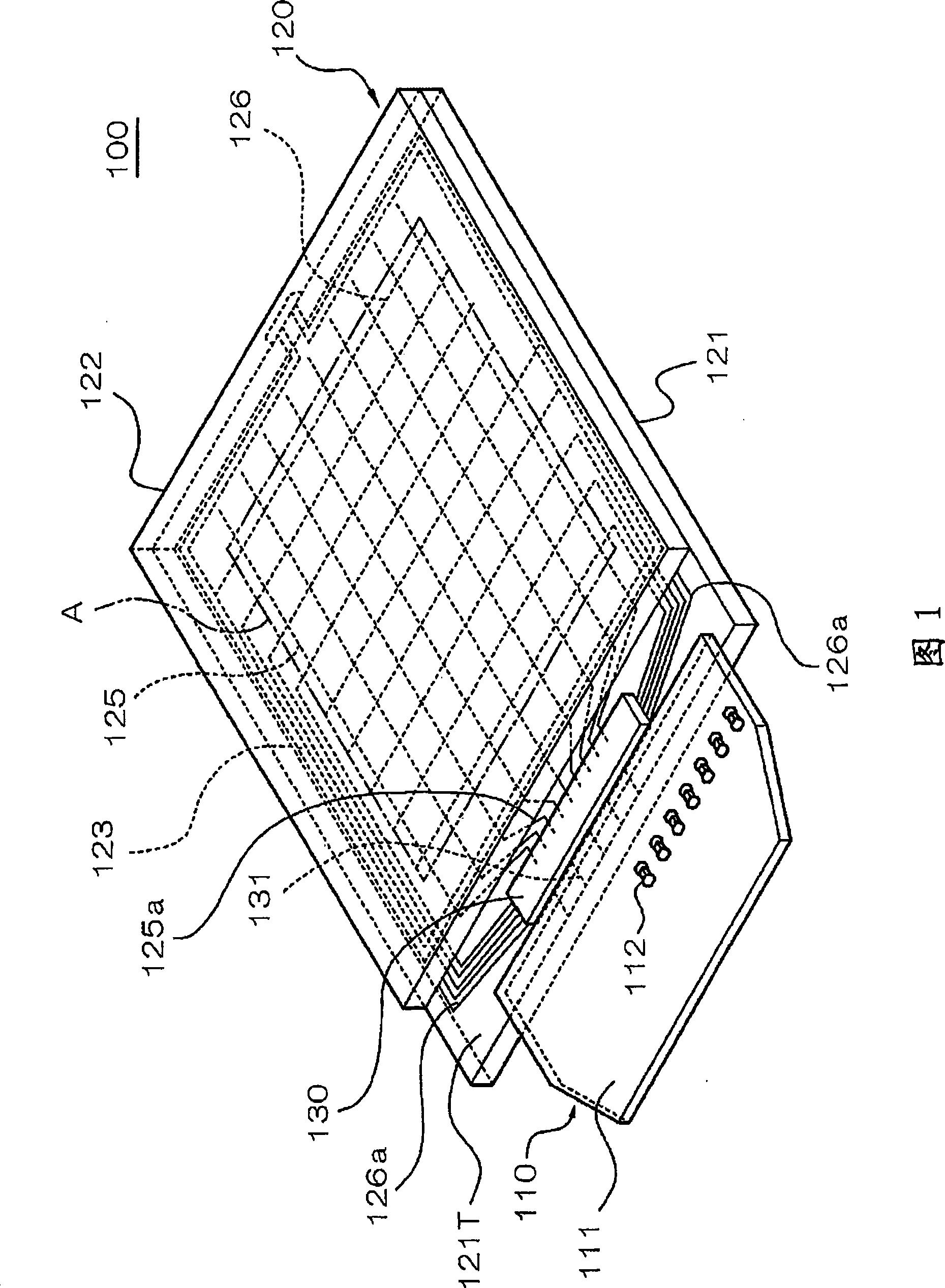

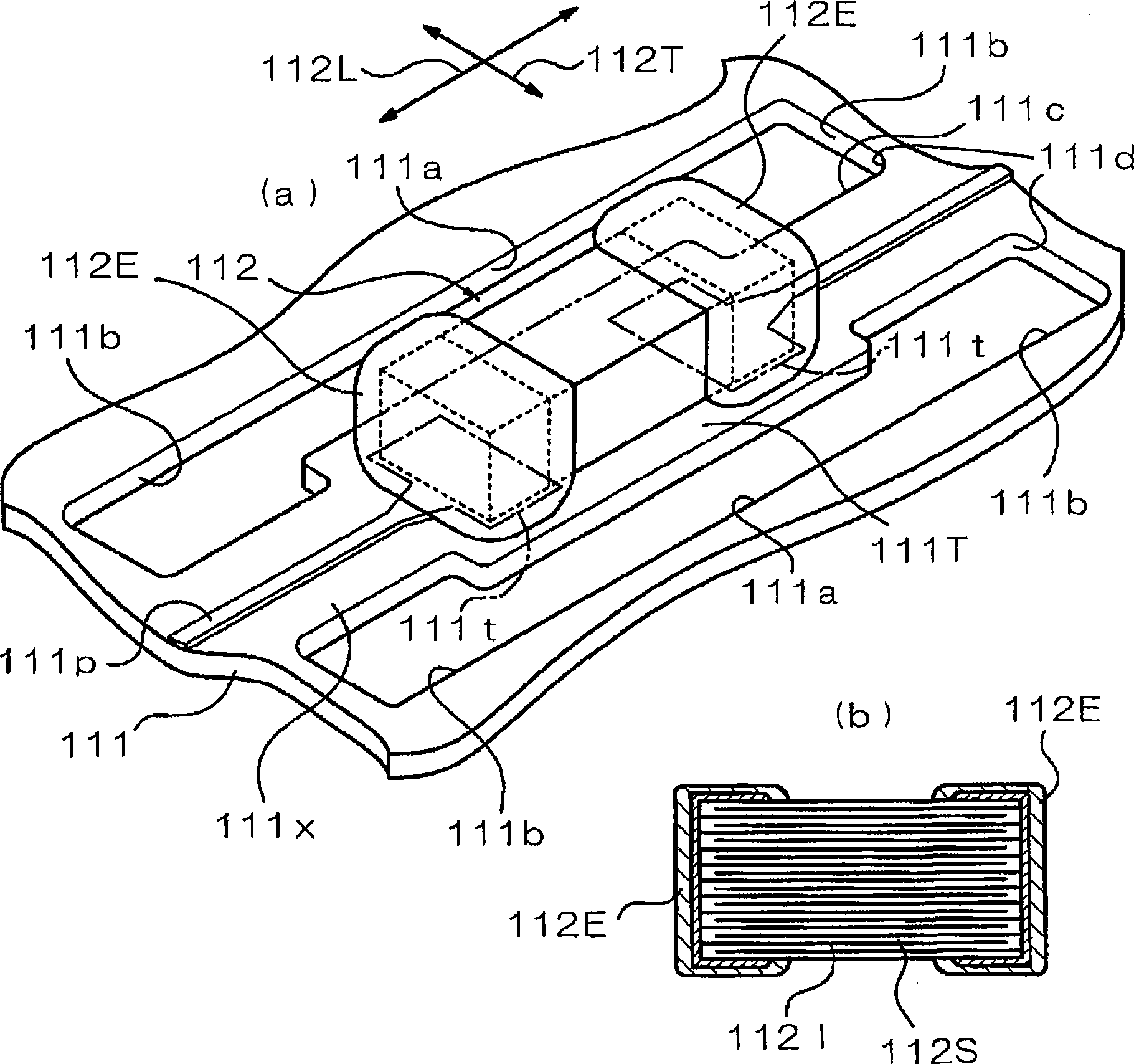

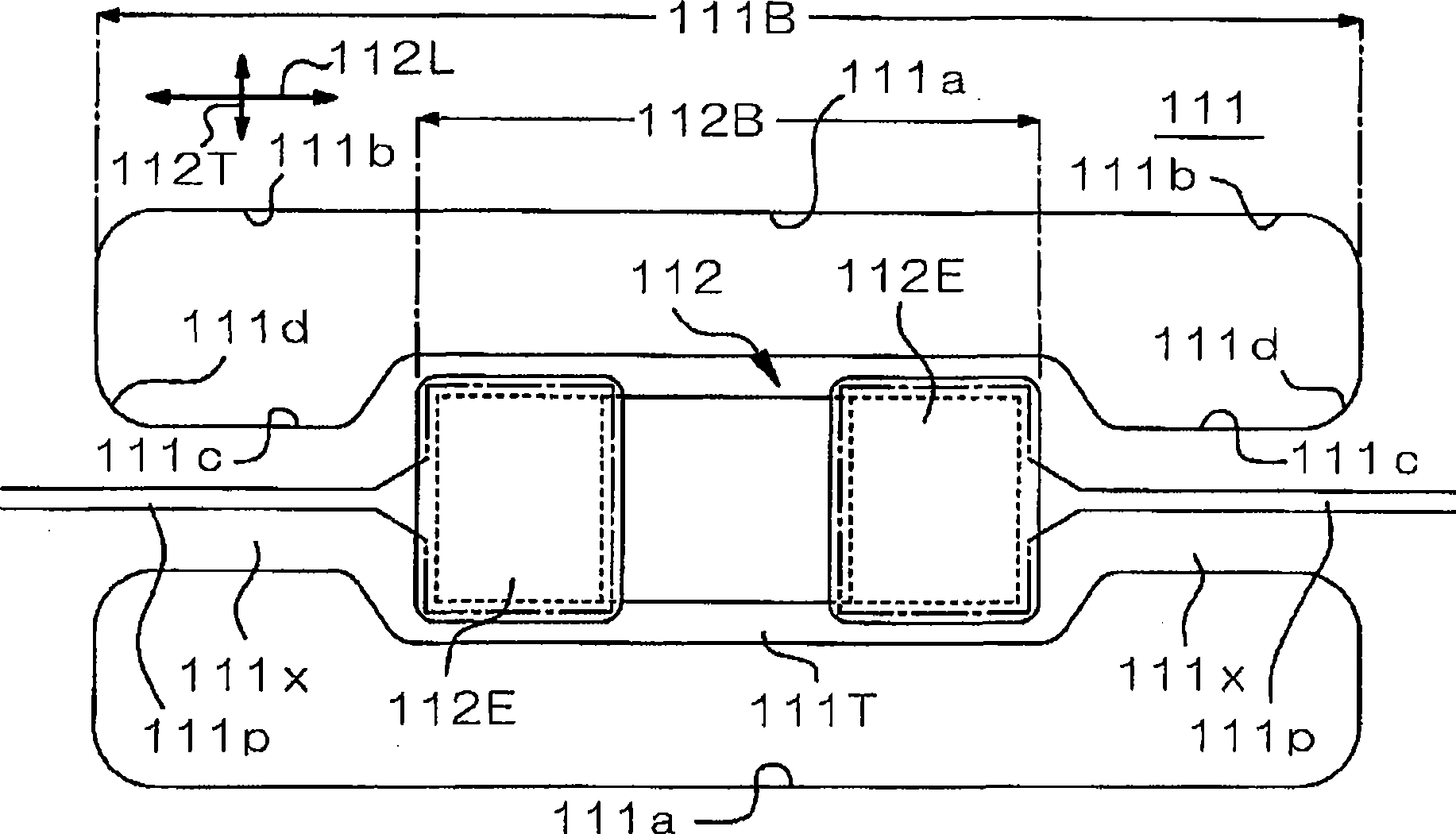

[0057] Next, embodiments of the present invention will be described in detail with reference to the drawings. FIG. 1 is a schematic perspective view showing a schematic structure of an electro-optical device 100 including a mounting structure as an embodiment of the present invention. The electro-optical device 100 of this embodiment includes a mounting structure 110. This mounting structure 110 is a mounting structure in which, for example, an electronic component 112 as a multilayer ceramic capacitor is mounted on a wiring board 111 made of a flexible wiring board. The wiring board 111 has: a plate-shaped resin base material made of an insulating resin material such as polyimide, and wiring not shown made of aluminum, copper, etc., formed on the surface of the resin base material; Equipped with surface resist, cover film, etc. covering these parts.

[0058] The electro-optical device 100 has an electro-optical panel 120 connected to the above-mentioned mounting structure 110. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com