Liquid filling machine

A filling machine and filling technology, applied in the directions of liquid materials, packaging, transportation and packaging, can solve problems such as a large number of foam, and achieve the effect of avoiding foam and avoiding standing and stratification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

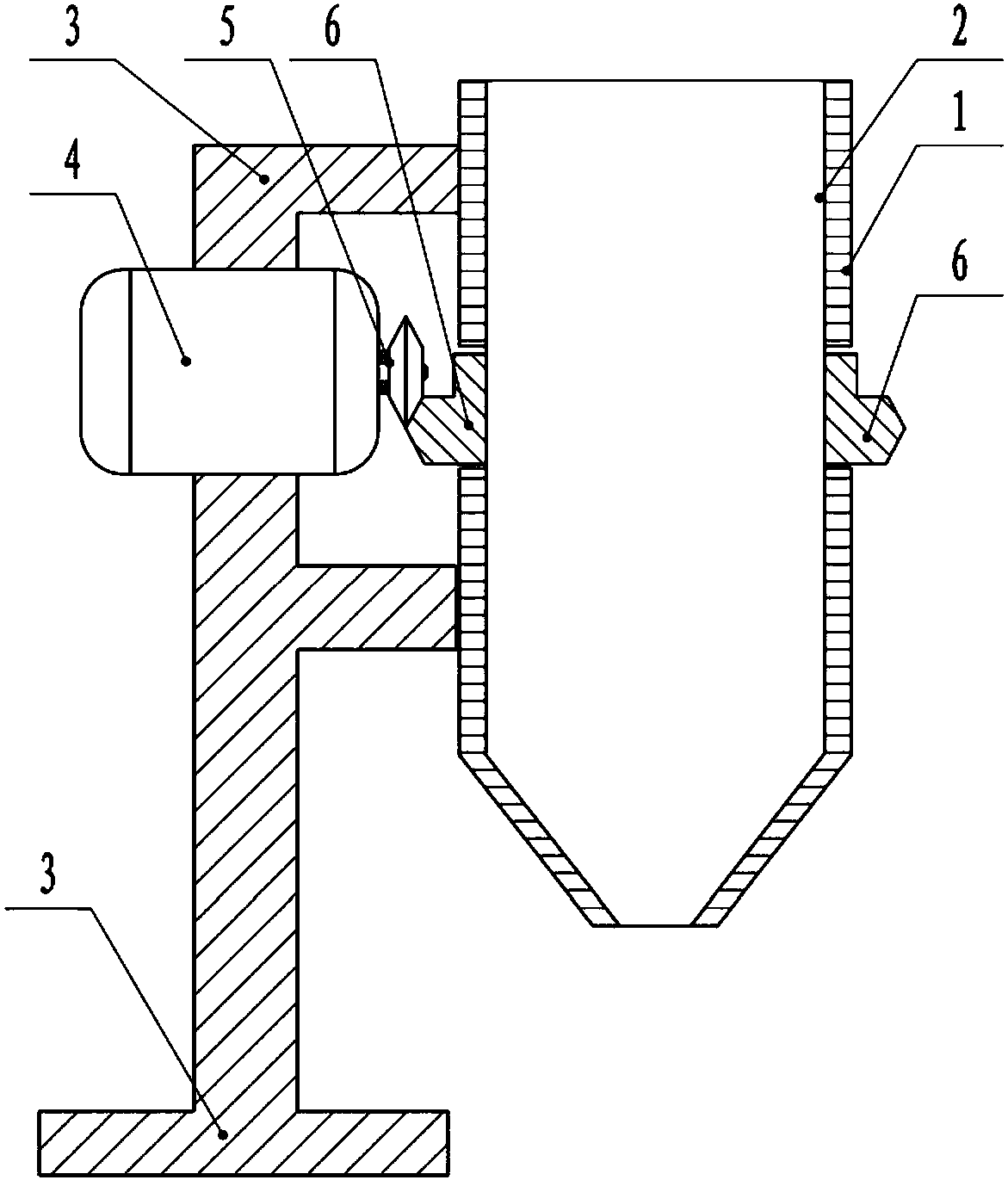

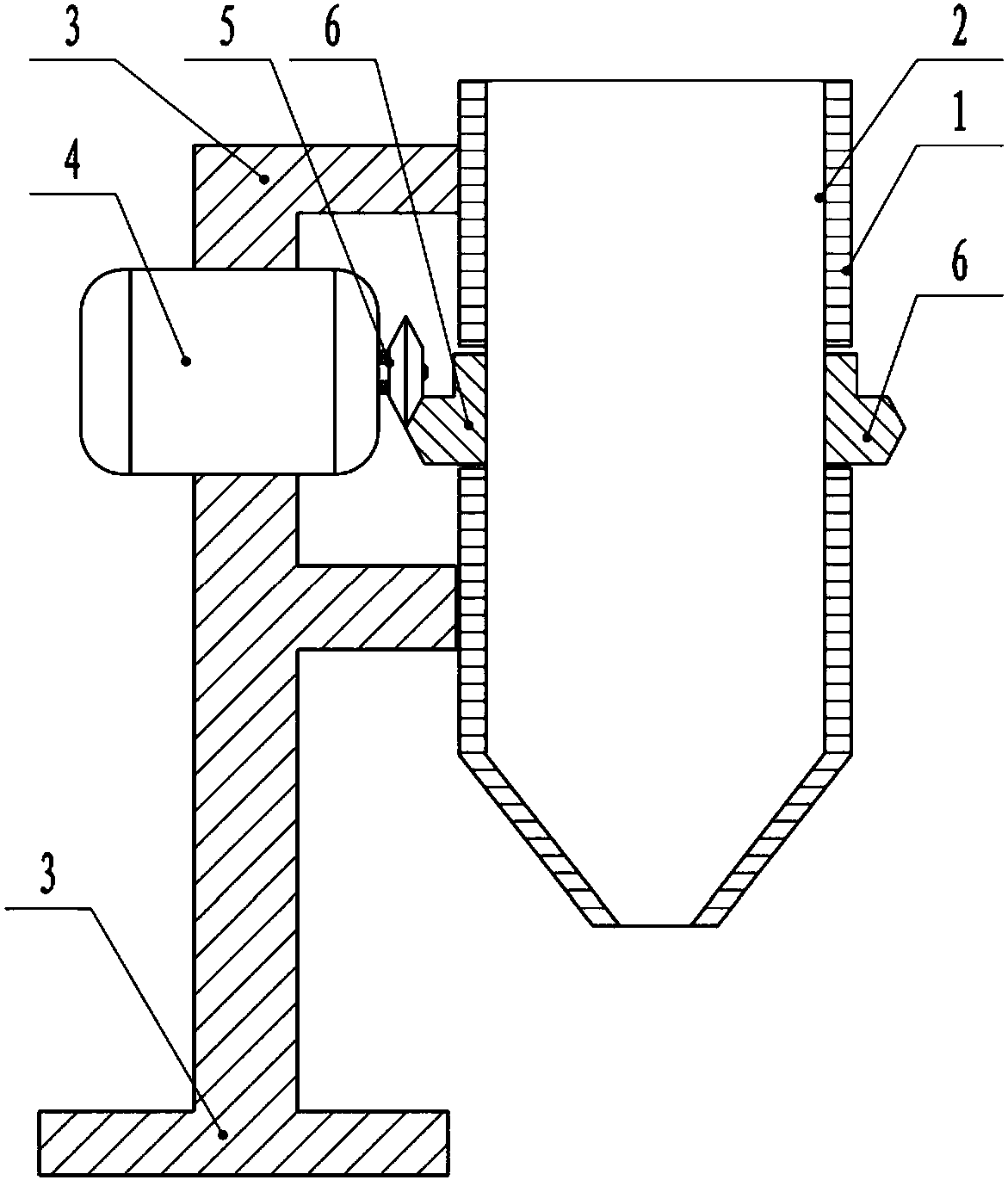

[0009] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

[0010] Such as figure 1 In the shown embodiment, this liquid filling machine includes a filling barrel body 2, a base 3, a sleeve 1 and a power machine 4, the base 3 is "F" shaped, and the sleeve 1 is divided into upper and lower parts And respectively fixed with the two transverse ends of the base 3, the filling barrel body 2 is installed inside the sleeve 1 and stuck in the upper and lower parts of the sleeve 1 by a circle of ring-shaped protrusions welded on the outside of the filling barrel body 2 The power machine 4 is installed on the base 3 at the seam between them. The output shaft of the power machine 4 is connected with the ring-shaped protrusion of the filling barrel body 1 through a gear transmission. The protrusion of the ring-shaped protrusion has a driven cone Groove for gear 6 fit. After the power machine 4 starts, it drives the gear 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com