Large-diameter heat exchanger inner sleeve assembling and disassembling tool and using method thereof

A technology for inner sleeves and loaders, applied in the field of heat exchanger manufacturing, can solve problems such as unsafe, difficult operation of inner sleeves of large-diameter heat exchangers, etc., to achieve easy operation, stable and reliable assembly and disassembly, and low operational risk Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] specific implementation plan

[0023] The present invention is described in conjunction with accompanying drawing:

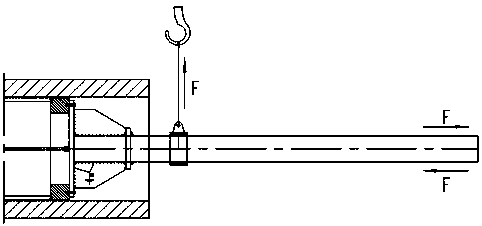

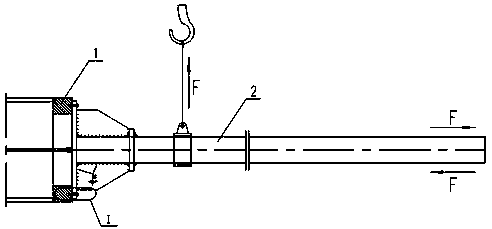

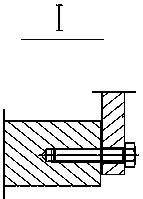

[0024] Large-diameter heat exchanger inner sleeve loading and unloading tooling, its structure is as follows Figure 4 As shown: the inner sleeve loading and unloading tooling assembly 2 is composed of a connecting plate 3, a rib plate 4, a reinforcing plate 5, a moving lug 6, and a balance bar 7; wherein the connecting plate 3, the rib plate 4, the reinforcing plate 5, the balance The rod 7 is welded as a whole; the mobile lifting lug 6 is set on the balance rod 7 and can move freely; Figure 5 As shown, the bolt holes processed on the upper circumference of the connecting plate 3 are matched with the bolt holes of the inner sleeve assembly 1; the connecting plate 3 and the inner sleeve assembly 1 adopt a bolt connection structure, such as image 3 As shown; the connection between the inner sleeve loading and unloading tooling assembly 2 and the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com