Lock washer for screwed fitting and preparation method thereof

A technology of threaded connectors and anti-loosening washers, which is applied in the direction of connecting components, threaded fasteners, screws, etc., can solve the problems that the anti-loosening washers are not anti-loosening, and cannot play the anti-loosening effect well, so as to improve the forming accuracy , Improve the anti-loosening effect area and improve the effect of anti-loosening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

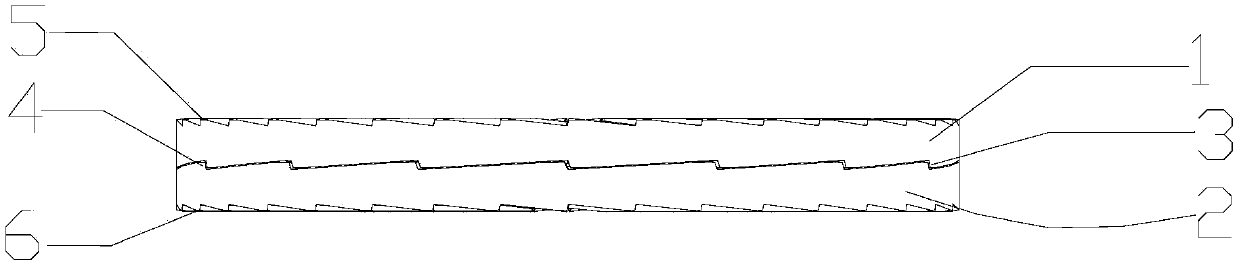

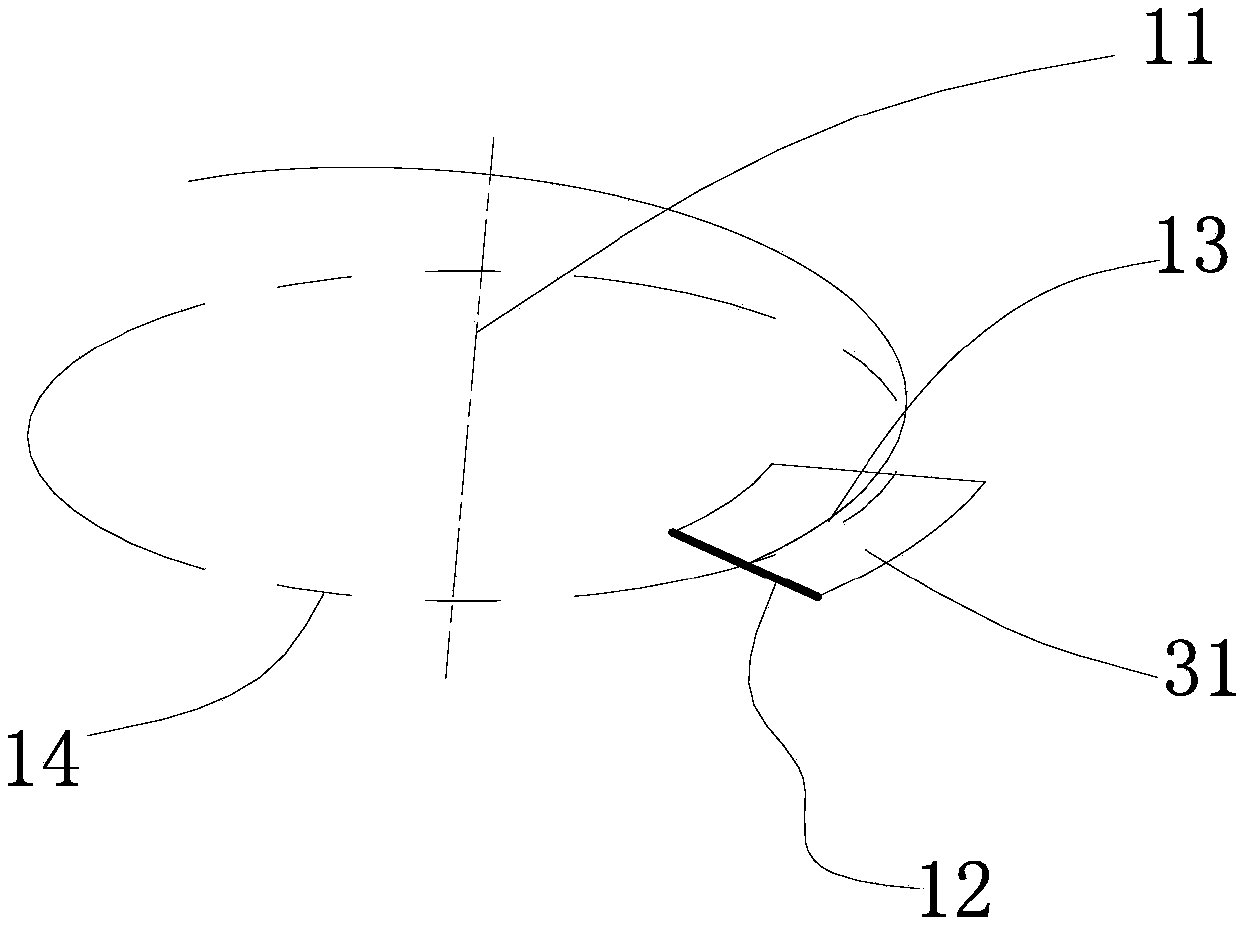

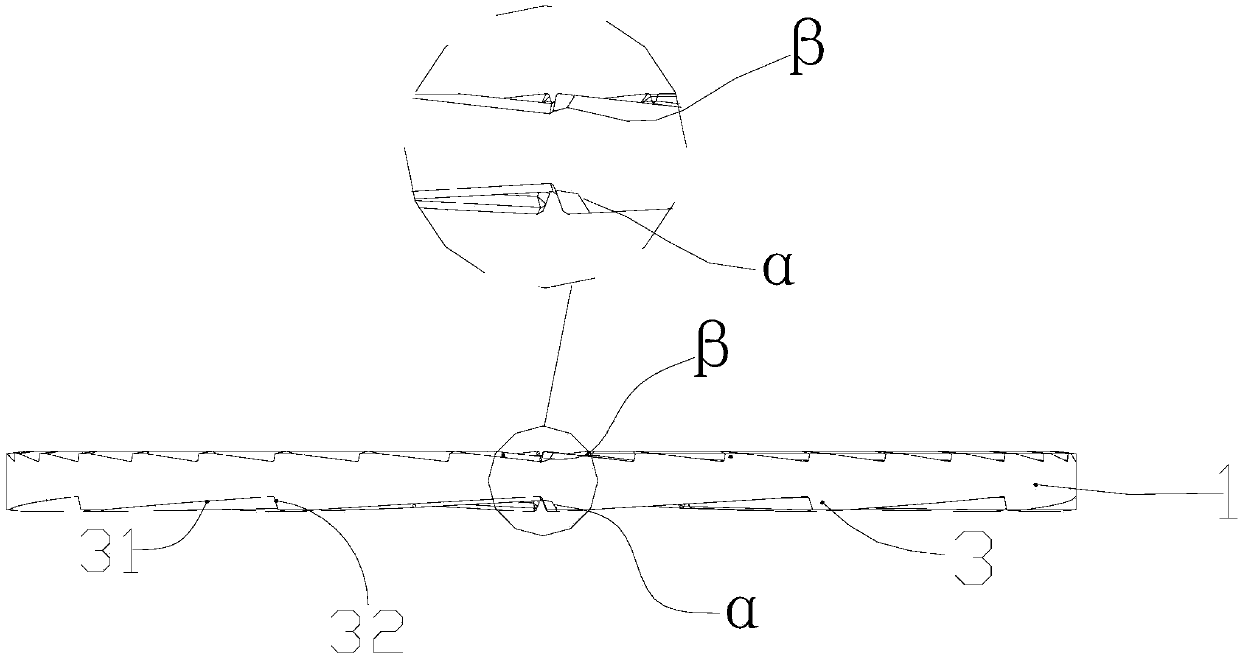

[0032] Specific embodiments of the present disclosure will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present disclosure, and are not intended to limit the present disclosure.

[0033] In this disclosure, in the absence of a contrary statement, the used orientation words such as "up, down, bottom, top" can refer to figure 1 The direction of the drawing, the specific use of the anti-loosening washer of the present disclosure is not limited by the "upper, lower, bottom, top" described in the present disclosure. The distance in this disclosure refers to the length of the shortest line between two components. In the present disclosure, the thread lead angle is the included angle between the tangent of the helix (wire) of the threaded connector (helix surface) on the medium-diameter cylinder and the plane perpendicular to the axis.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Helix angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com