A toothed flange locknut

A technology of anti-loosening nuts and flanges, which is applied in the direction of nuts, screws, bolts, etc., can solve problems such as easy loosening, and achieve the effect of increasing friction, preventing position slippage, and preventing loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

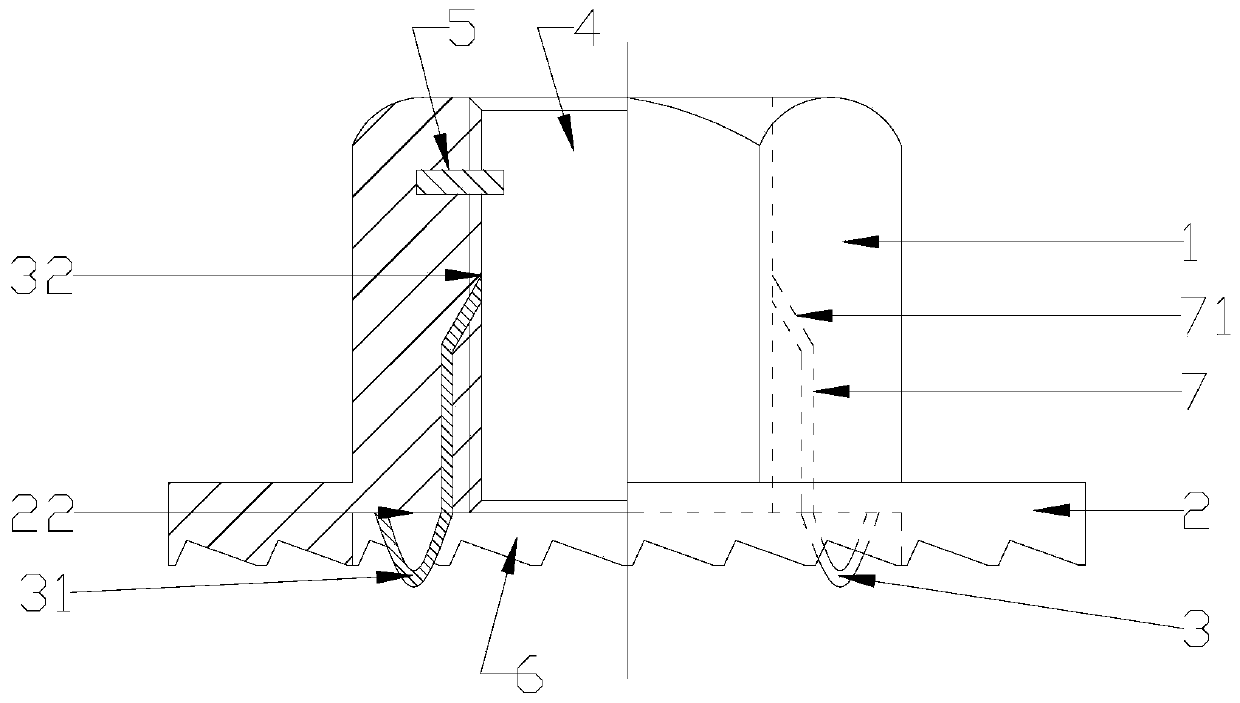

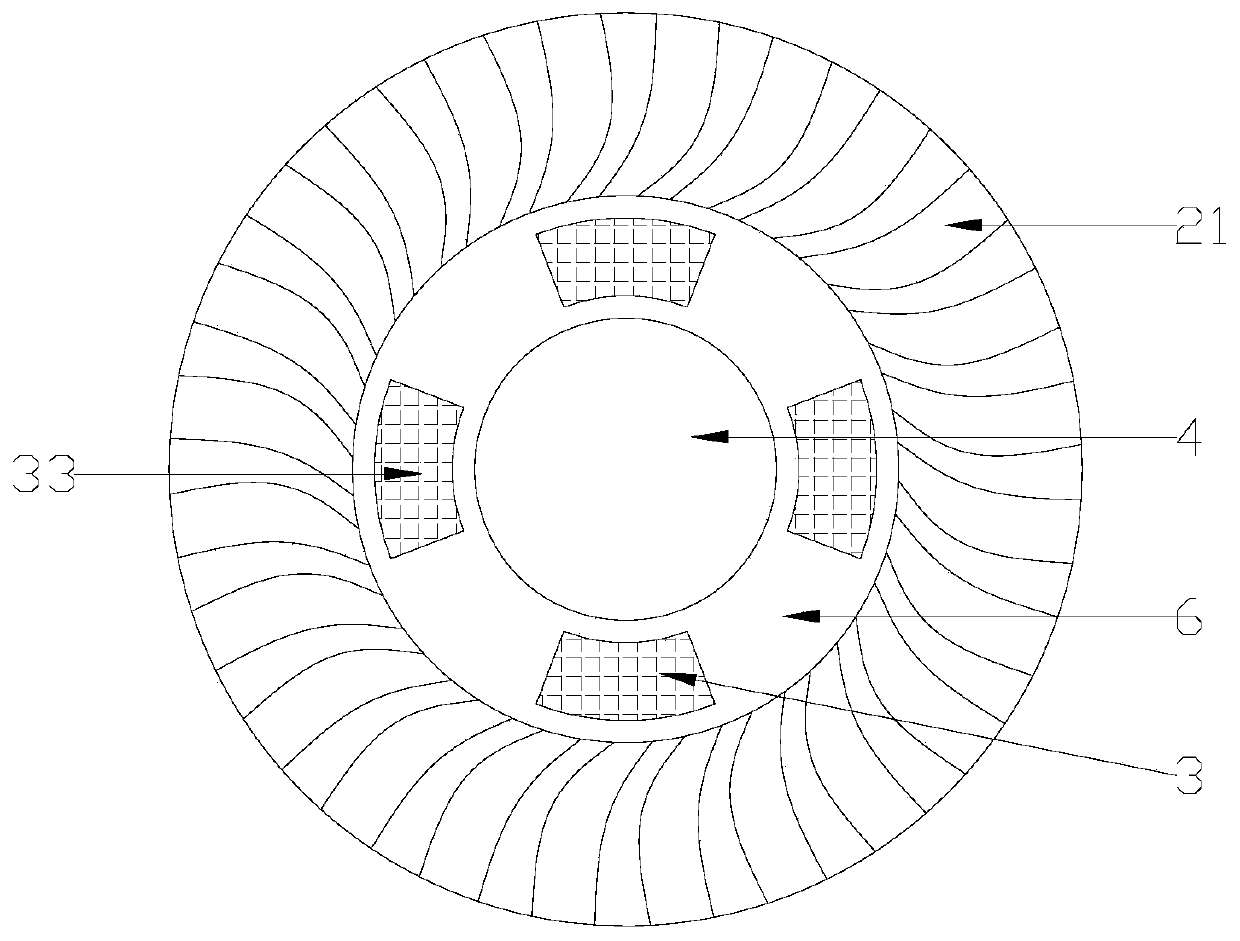

[0015] refer to figure 1 with figure 2 , a toothed flange anti-loosening nut according to the present invention, comprising a nut body 1 and an annular flange 2 integrally connected with the nut body 1, the nut body 1 and the flange 2 are provided with threaded holes 4 along the axial direction The side of the flange 2 away from the nut body 1 is provided with a coaxial counterbore 6 connected with the threaded hole 4, and the nut body 1 and the flange 2 are provided with several threaded holes 4 A through groove 7, the two ends of the through groove 7 communicate with the threaded hole 4 and the counterbore 6 respectively, and the end of the through groove 7 away from the flange 2 is provided with a bent portion 71 oblique to the threaded hole 4, Also insert stop piece 3 in described through groove 7, one end of described stop piece 3 stretches out through groove 7 and is fixed on the platform 22 between threaded hole 4 and counterbore 6, and the extension of described stop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com