A jujube stone removal device

A technology of jujube core and bottom plate, which is applied in the field of jujube core removing device, can solve the problem that the work efficiency needs to be improved, and achieve the effects of ingenious design, compact device structure and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

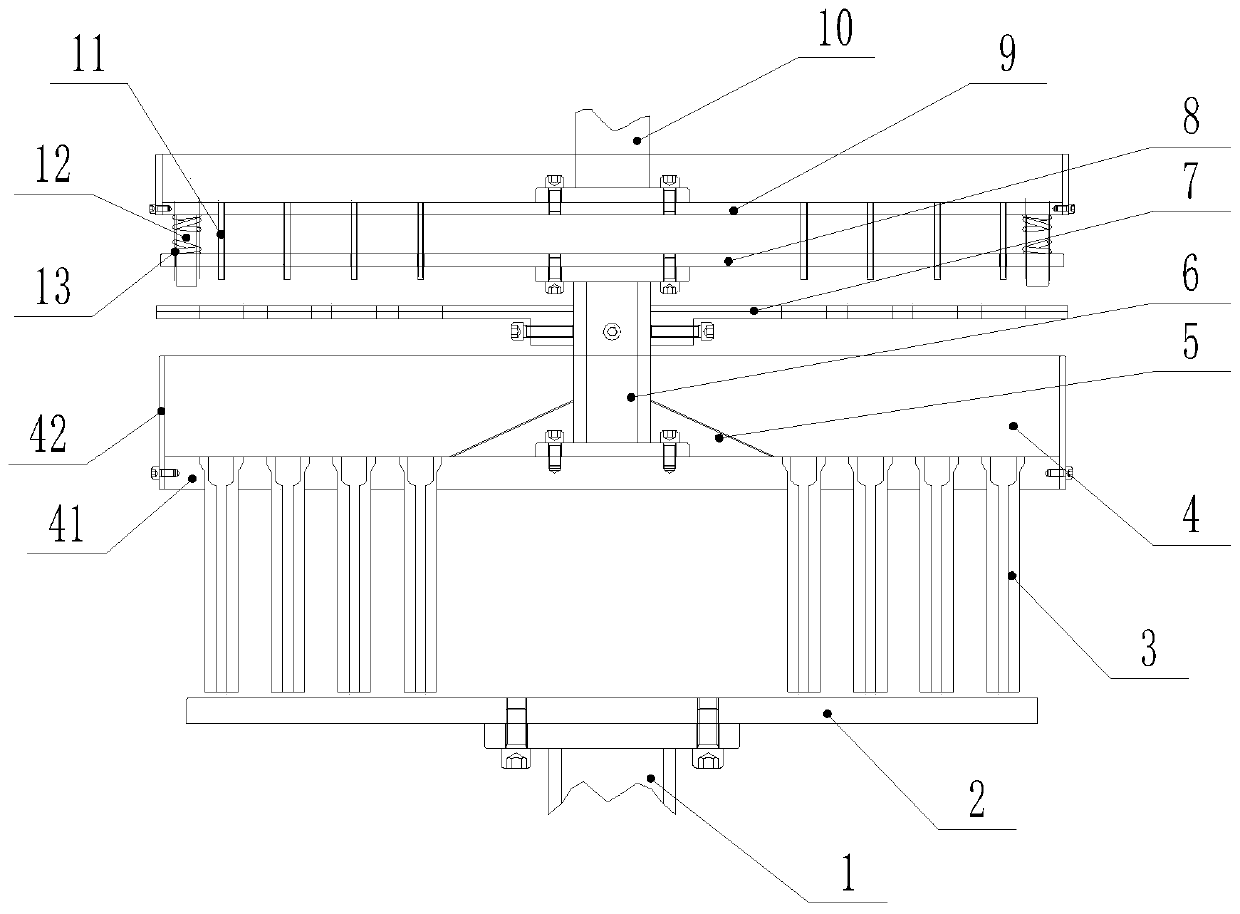

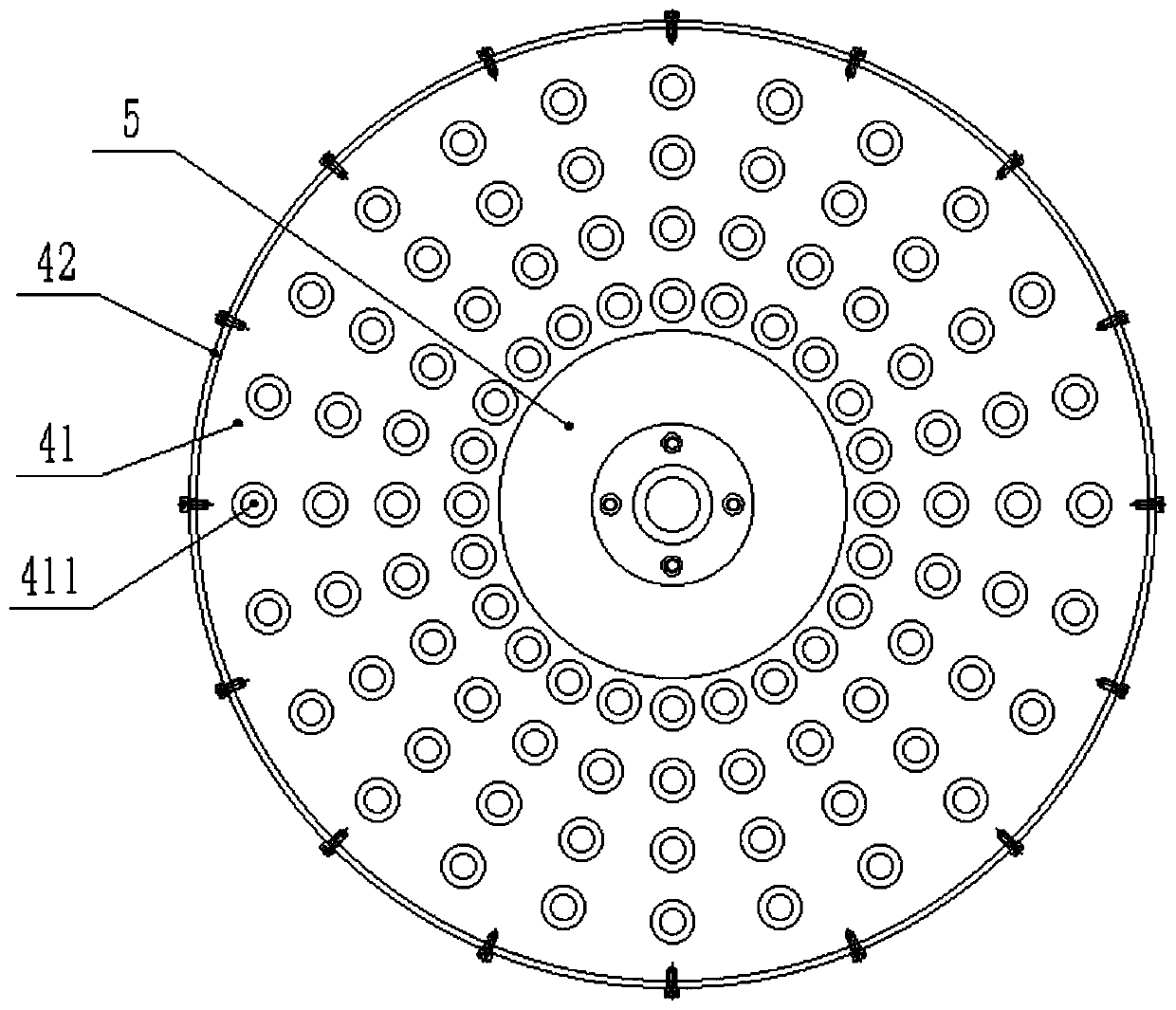

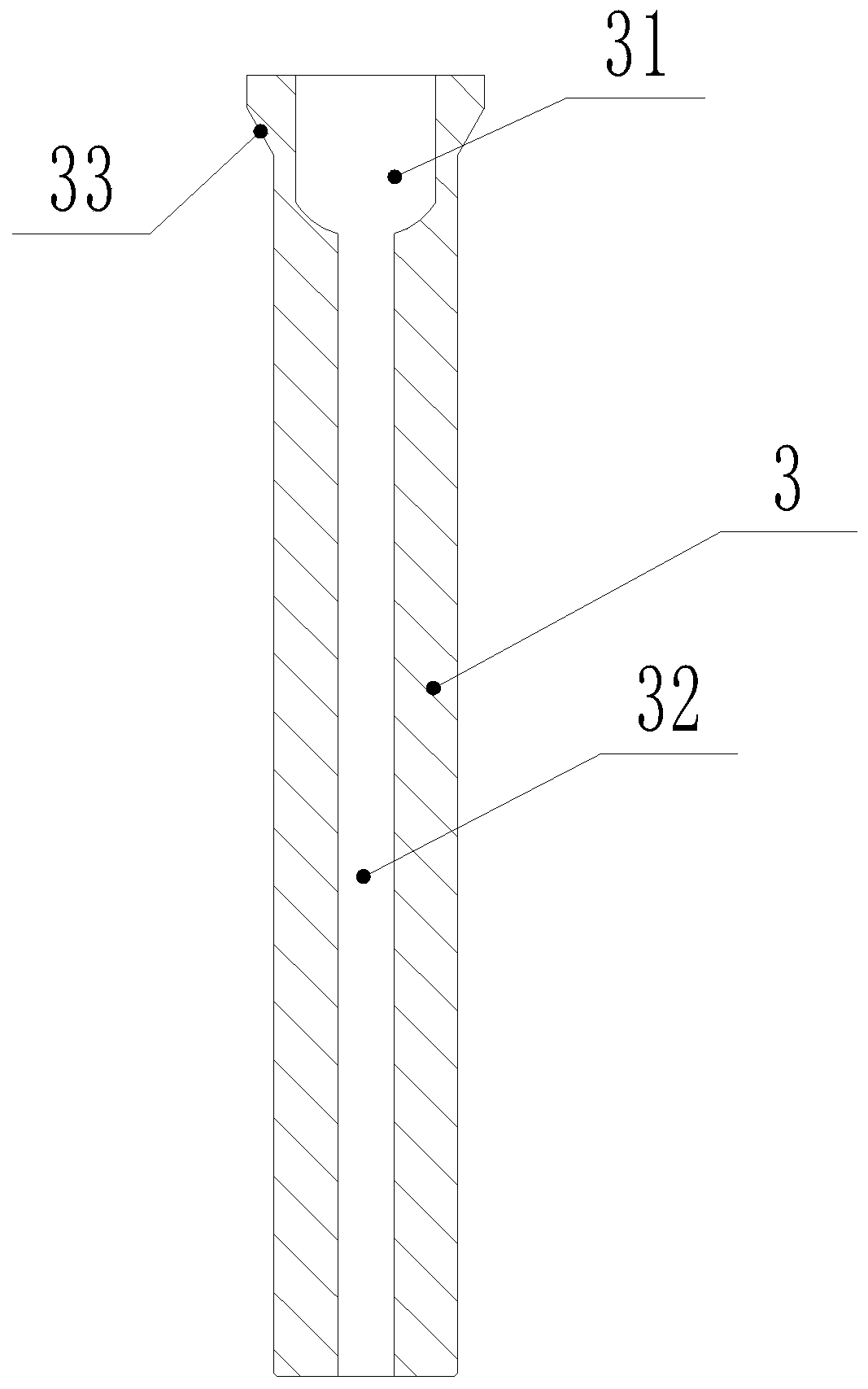

[0031] Such as figure 1 As shown, a kind of jujube stone removal device described in the embodiment of the present invention includes a material management tray 4, and the material management tray 4 is formed by a round bottom plate 41 and a coaming plate 42, and the round bottom plate 41 is regularly processed. Strip tube positioning hole 411; strip tube 3, the strip tube 3 is placed in the strip tube positioning hole 411 and can move up and down along the material tray 4, the strip tube 3 at least includes In the groove 31 that holds jujube 14 and is positioned at the column hole 32 below described groove 31; The upper end processing oblique shoulder 33 of described bar tube 3, matches with the upper end of bar tube positioning hole 411, is used for bar The limit of shaped tube 3. The grid plate 8 is located above the material sorting tray 4, and is connected with the round bottom plate 41 through the flange 6. The grid plate 8 is fixed by a bracket and can drive the materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com