Washing machine

A technology for washing machines and clothes, applied in the field of washing machines, can solve the problems of generating flow resistance, increasing time, and unable to spray water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, a washing machine according to an embodiment of the present invention will be described with reference to the accompanying drawings.

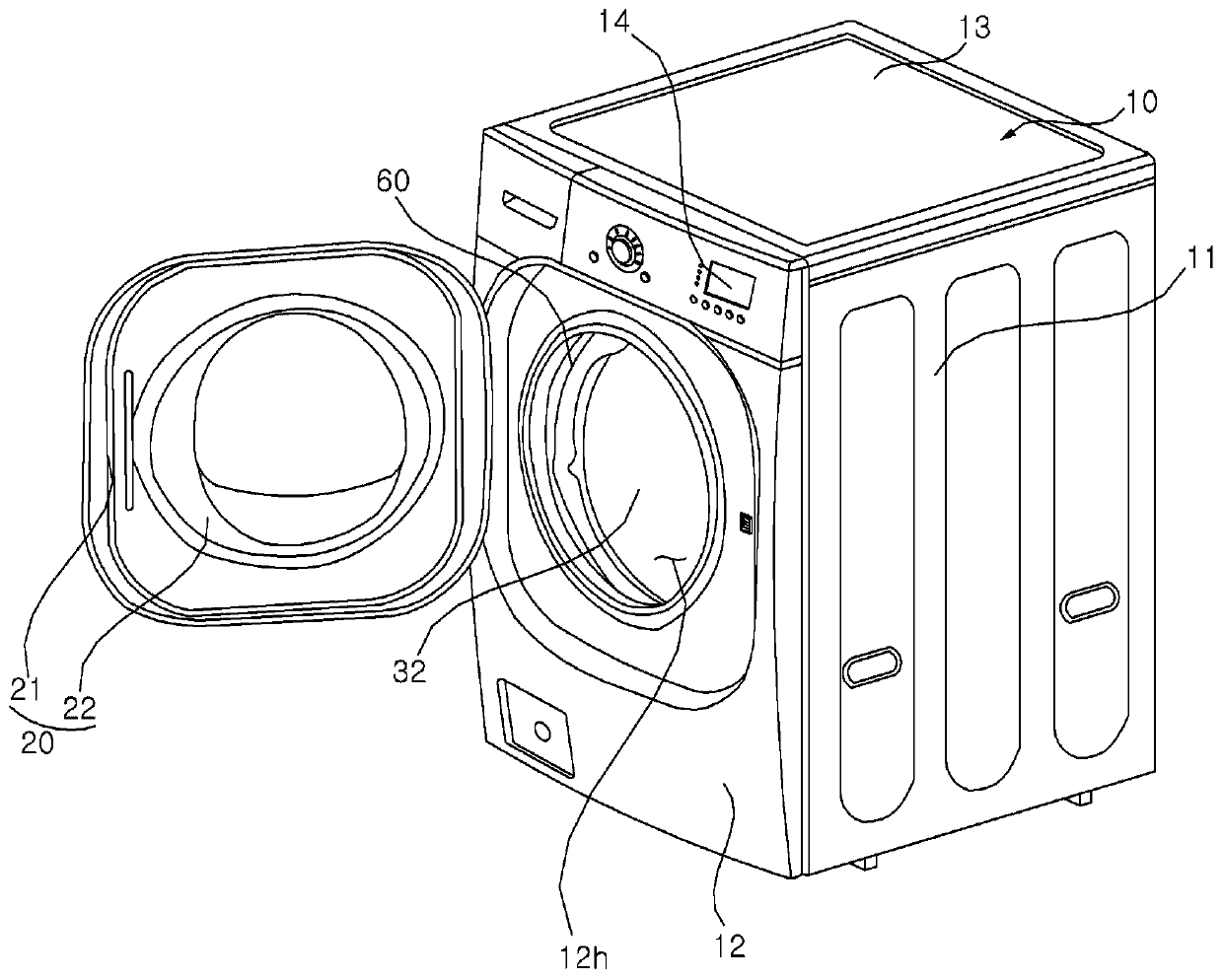

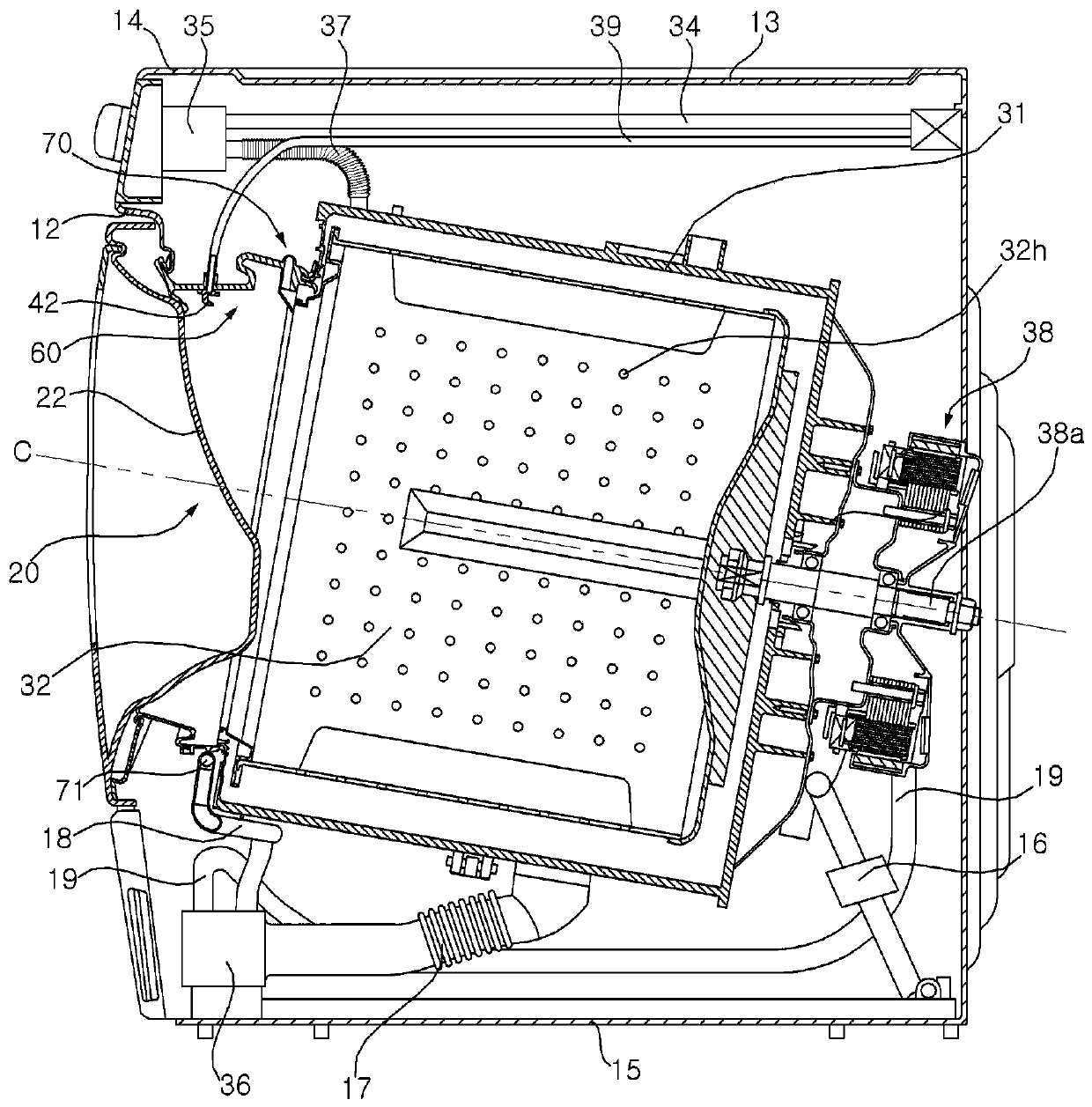

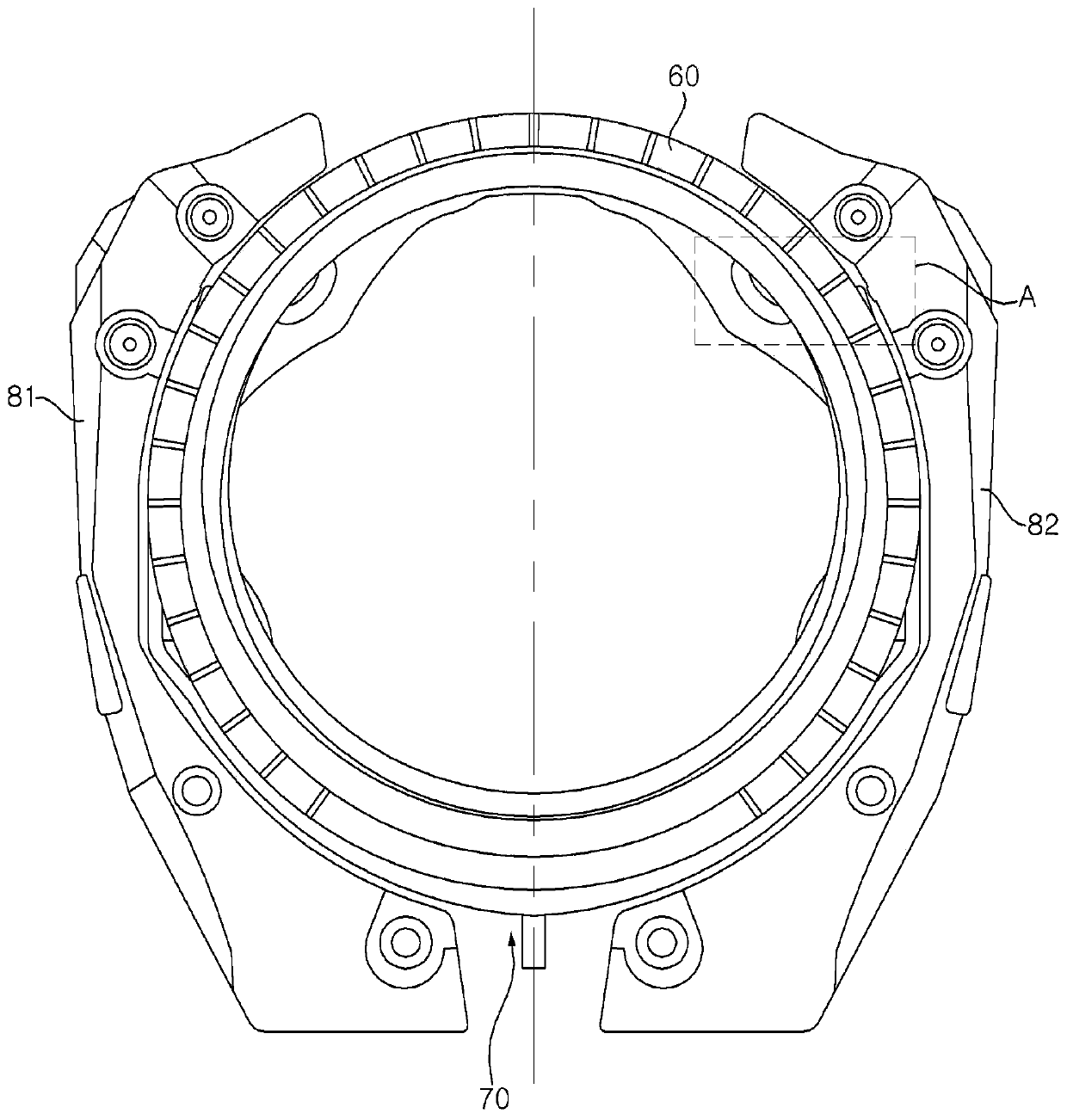

[0039] figure 1 is a perspective view illustrating a washing machine according to an embodiment of the present invention, and figure 2 Yes figure 1A cutaway side view of the washing machine shown in .

[0040] refer to figure 1 and figure 2 , The washing machine according to the embodiment of the present invention includes a casing 10 forming an appearance. The housing 10 is provided with an inlet 12h formed on its front surface, through which laundry is inserted. The casing 10 includes a box body 11 and a front panel 12, the box body 11 has an open front surface, a left surface, a right surface and a rear surface, the front panel 12 is coupled to the open front surface of the box body 11 and the input port 12h is formed on panel 12. Bottom and upper surfaces of the case 11 are opened, and a horizontal base 15 suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com