Coplanar complete-mining local-filling mining method of mine resources

A technology of mining method and coal mining method, which is applied in the direction of filling, safety device, ground mining, etc., can solve problems such as environmental pollution, difficulty in retaining roadway support along gobs, etc., achieve safe and efficient green mining, and reduce surrounding rock Effect of deformation and balance rock movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

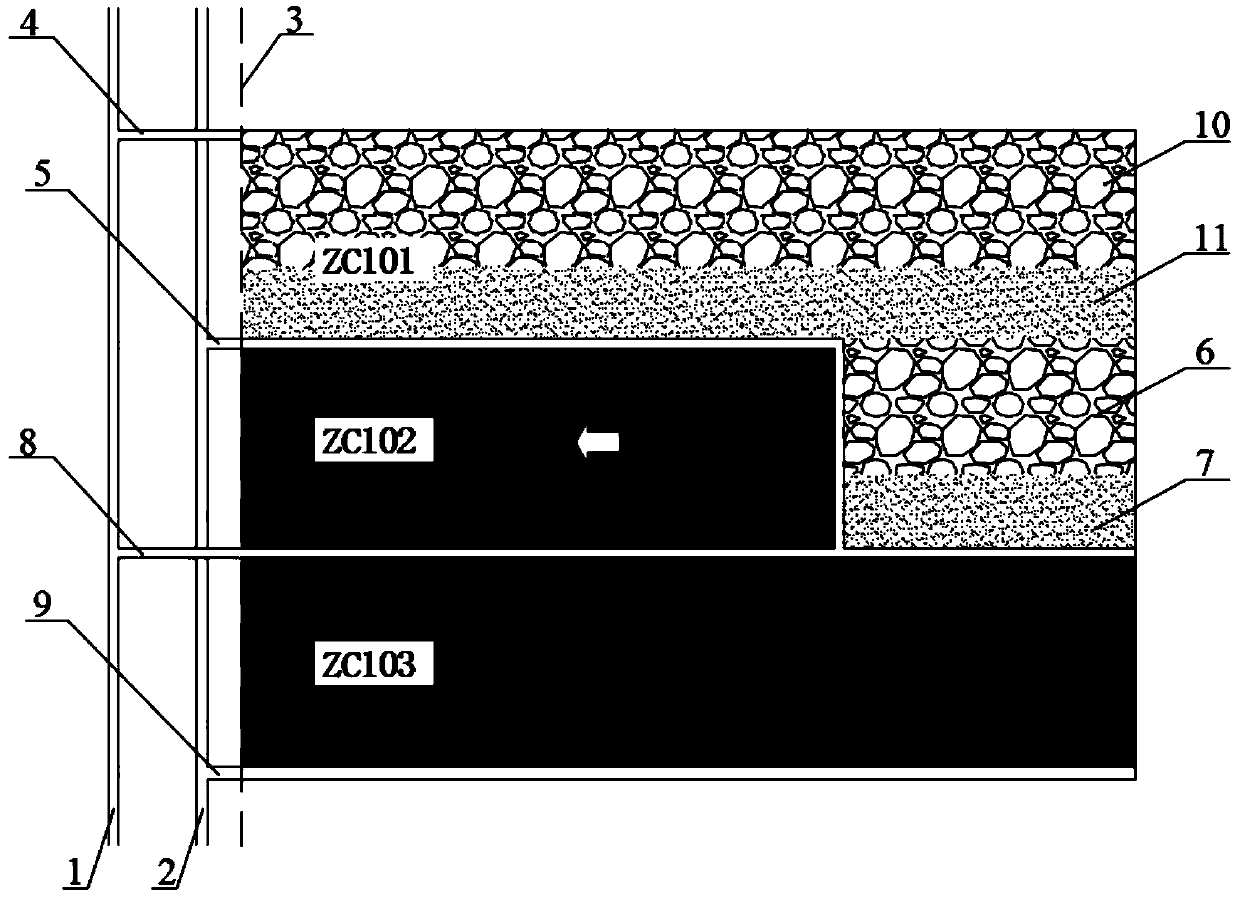

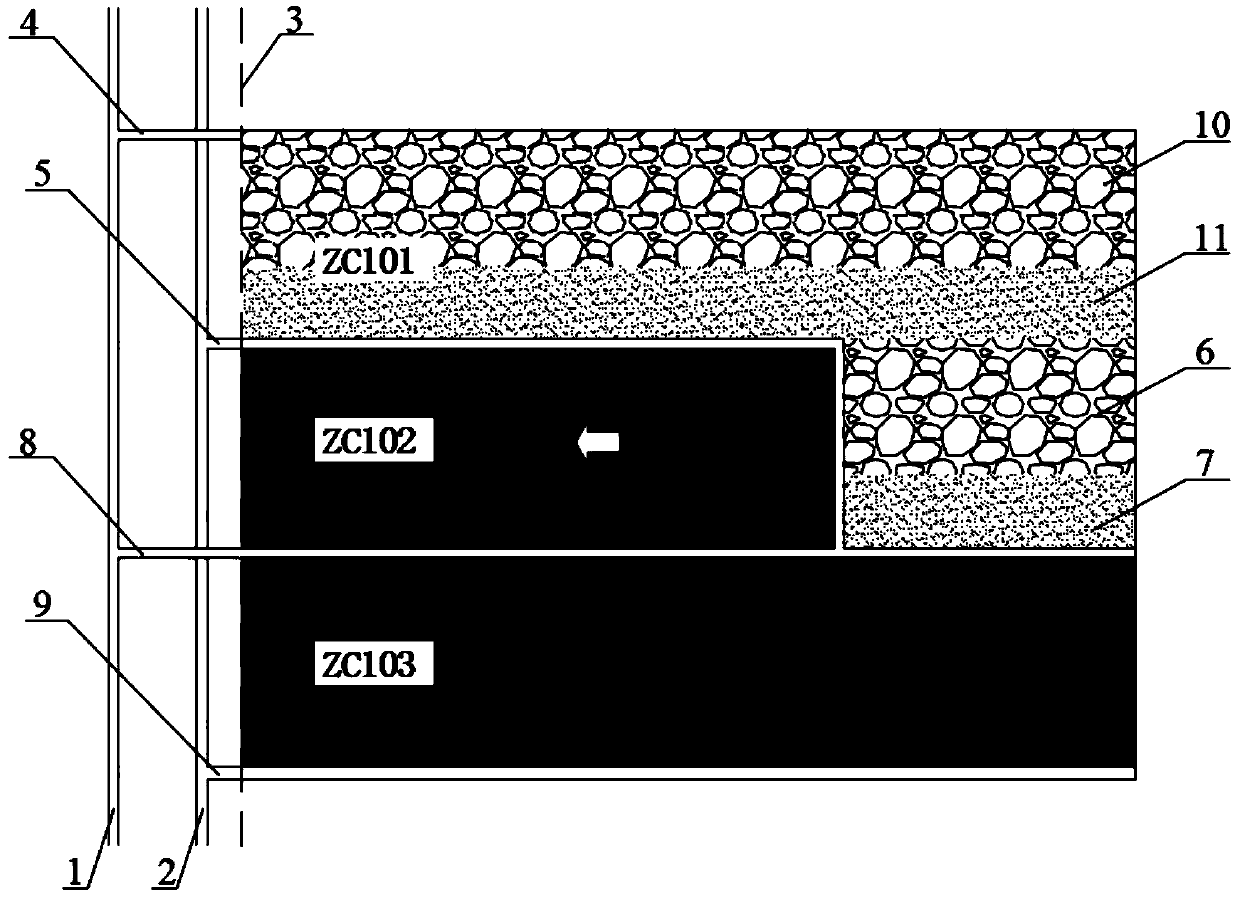

[0019] Below in conjunction with accompanying drawing, a kind of mine resource mining method of the present invention will be described in detail.

[0020] Taking the No. 1 mining area of a certain mine as an example, the working faces of this mine are all full-mining and mixed-mining faces on the same plane. Currently, the ZC102 mixed mining face is being mined. The depth of the coal seam is -600m~-800m, and the average thickness of the coal seam is 3.5m. , the average dip angle is 8°, the average thickness of the immediate top is 1.42m, mainly gray mudstone, the average thickness of the basic top is 5.52m, mainly dark gray sandy mudstone, and the average thickness of the immediate bottom is 4.15m, mainly gray black mudstone. The length of the mixed mining face is 260m, the advancing length is 1500m, the length of the solid filling section of the mixed mining face is 100m, and the length of the fully mechanized caving section is 160m. The mixed mining face adopts a set of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com