A fracturing process suitable for infill development of shale gas wells

A shale gas well and fracturing technology, which is applied in the field of fracturing technology for intensified development of shale gas wells, can solve problems such as difficult breakthroughs, limited effectiveness, and reduced formation pressure coefficients, and achieve the effect of increasing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

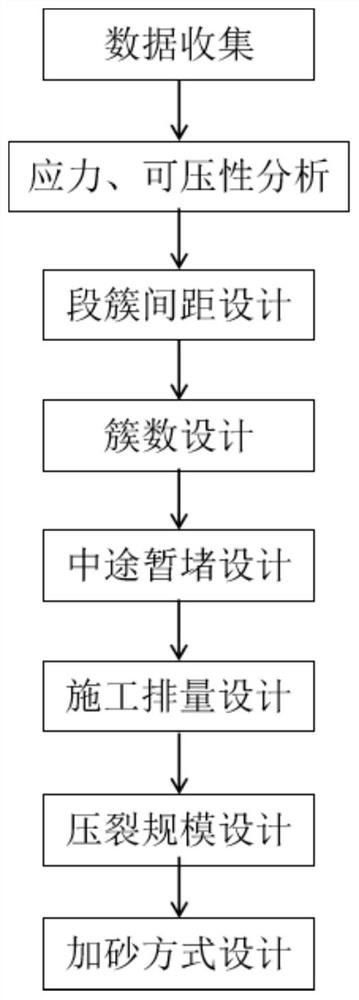

[0031] see Figure 1-4 , a fracturing process suitable for infill development of shale gas wells, comprising the following steps:

[0032] (1) Data collection, including well logging data and regional in-situ stress prediction results;

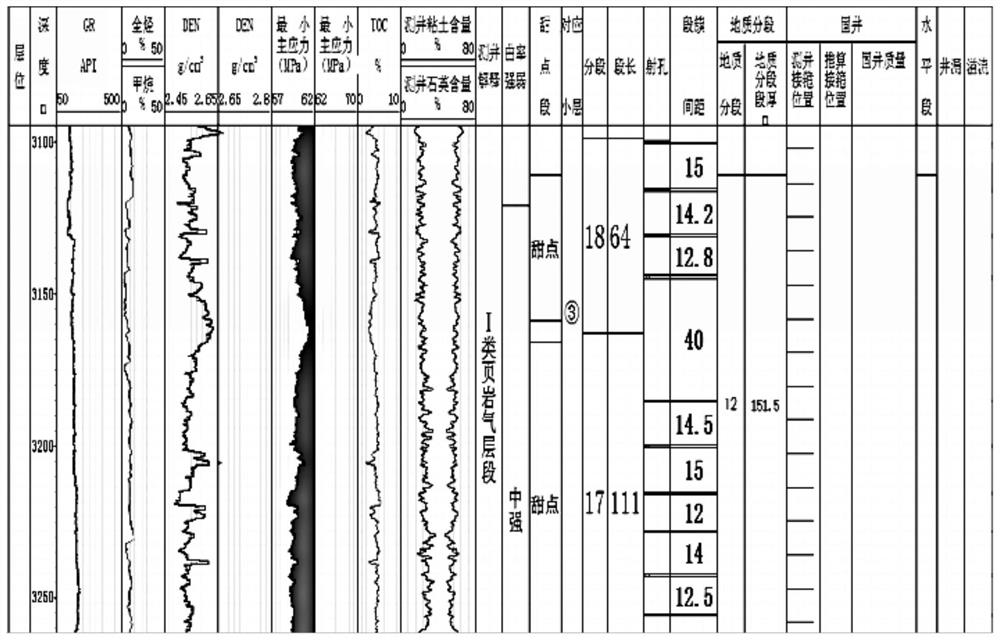

[0033] (2) Stress and compressibility analysis. According to the water stress difference in the area where the horizontal well is located, the stress value and the change of the stress field under different fracture spacing conditions are simulated and calculated. The different fracture spacing conditions include 15, 20, 25, 30, and 35m. Other distances are also possible;

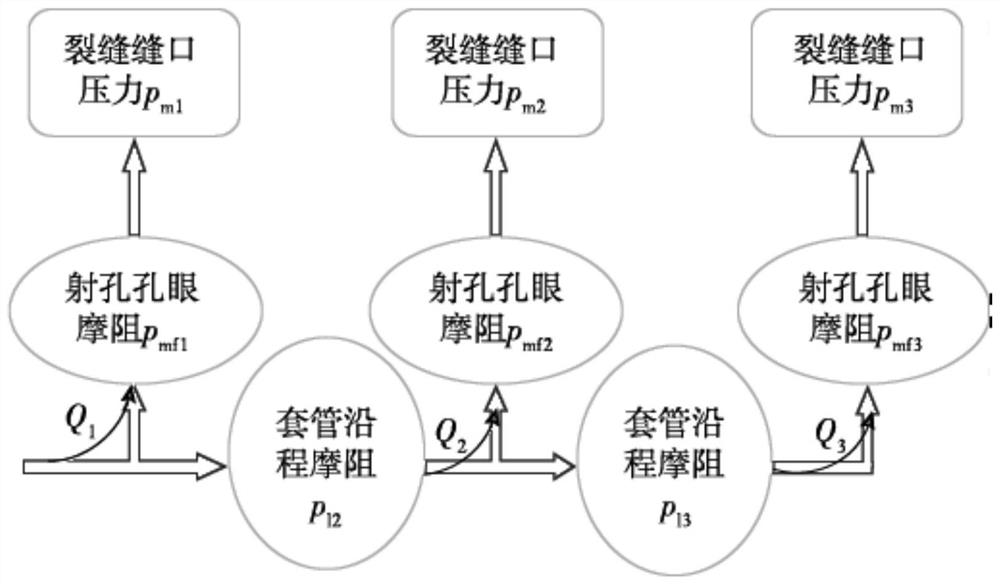

[0034] (3) Segment-cluster spacing design, select the segment-cluster spacing based on the induced stress difference obtained by the simulation calculation in step (2), and minimize the segment-cluster spacing within an appropriate range. The section-cluster spacing includes section spacing and cluster spacing, and the selection of the cluster spacing should meet the requ...

Embodiment 2

[0041] The other content of this embodiment is the same as that of Embodiment 1, the difference is that when sand is added continuously, 3 kinds of particle sizes are combined, and the initial powder pottery-sand ratio is designed to be 3%, so as to ensure the safety of construction and at the same time play the role of grinding holes. The subsequent sand ratio is mainly used to fill the micro-fractures in the near-wellbore zone, providing favorable conditions for the injection in the medium sand stage; the sand ratio in the medium sand stage starts at 3-4%, which acts as the main support for the fractures, and the highest sand ratio in this stage is generally designed It is 13-19%; the coarse sand is mainly selected for trailing at the final stage to achieve high conductivity support in the near-wellbore area, and considering the safety and effectiveness of on-site construction, the sand ratio is designed to be 14-17%.

[0042]The invention relates to a new shale gas fracturin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com